Treatment equipment for kitchen waste

A technology for processing equipment and kitchen waste, applied in the fields of grain processing, application, food science, etc., can solve the problems of waste, unable to realize the reuse of waste products, unable to target specific waste, etc., and achieve the effect of convenient and labor-saving operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

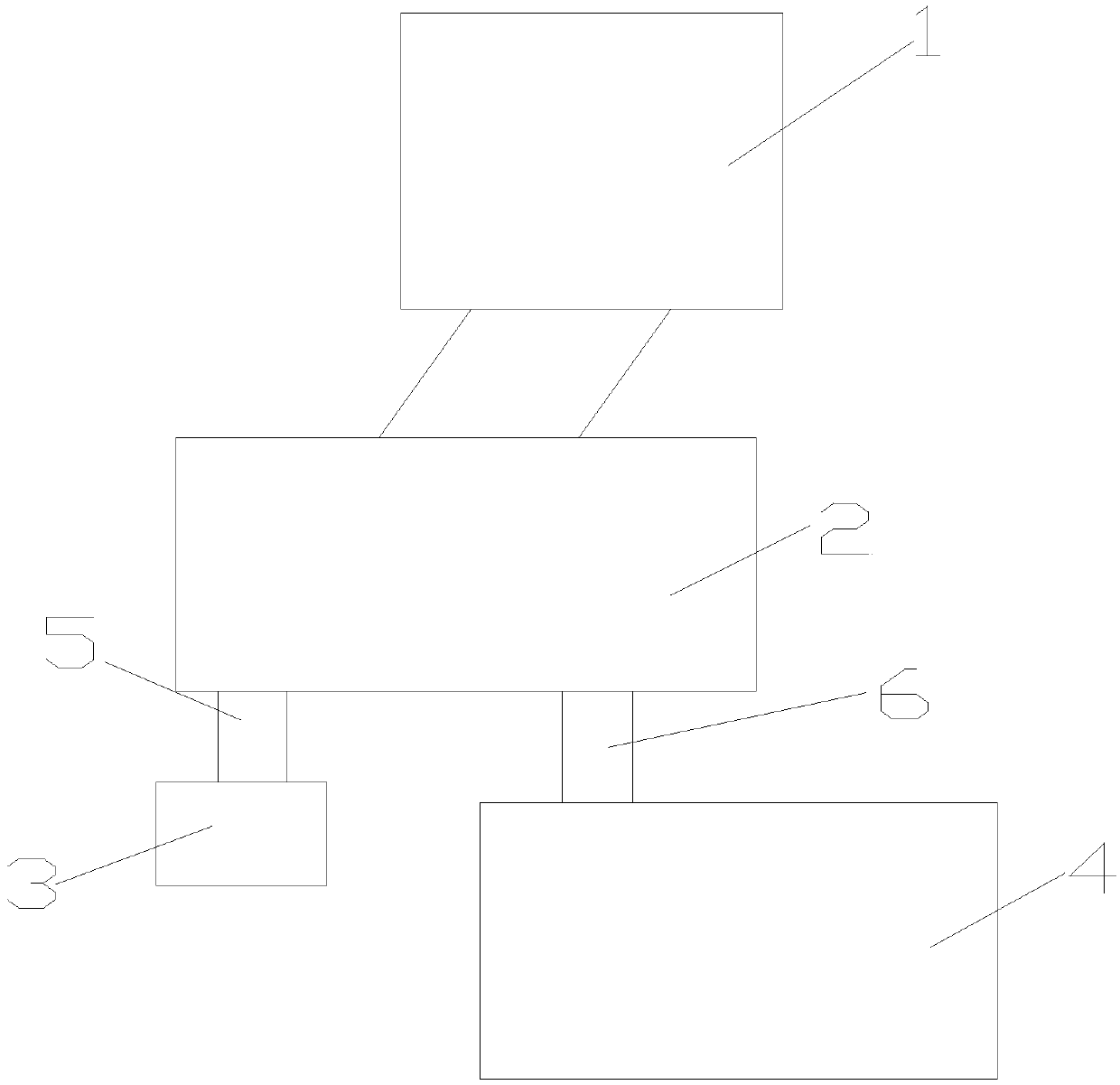

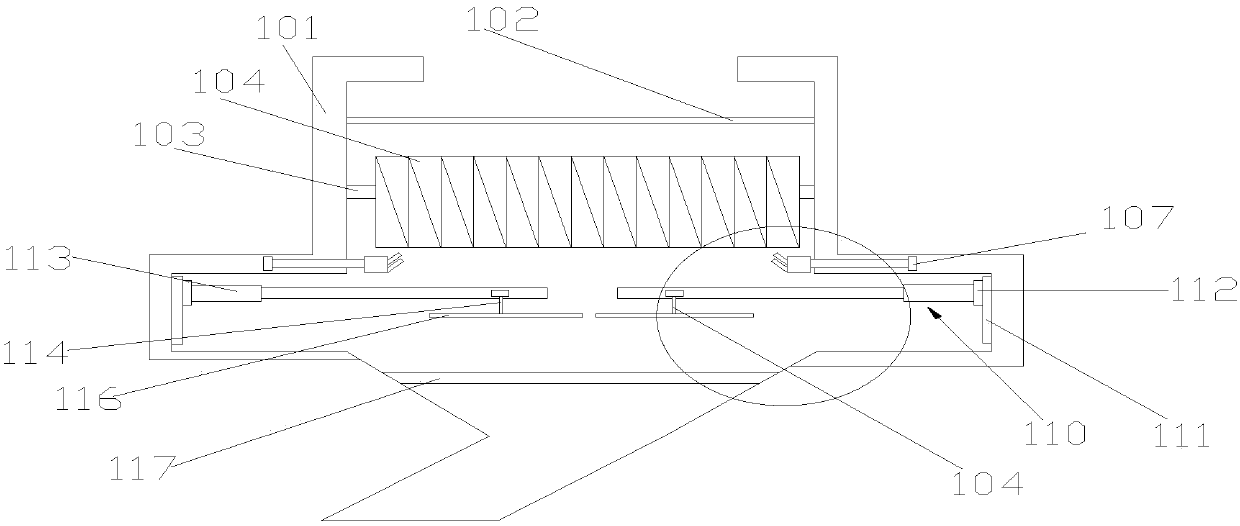

[0028] as attached Figure 1-11 The shown kitchen waste treatment equipment of the present invention includes a stirring device, a solid-liquid separation device, a solid processing device and an oil-water separator; the stirring device is located above the solid-liquid separation device; the solid-liquid separation device The lower end of the separation device is provided with a solid outlet pipe and a liquid outlet pipe; the lower end of the solid outlet pipe is provided with solid processing equipment; the lower end of the liquid outlet pipe is provided with an oil-water separator.

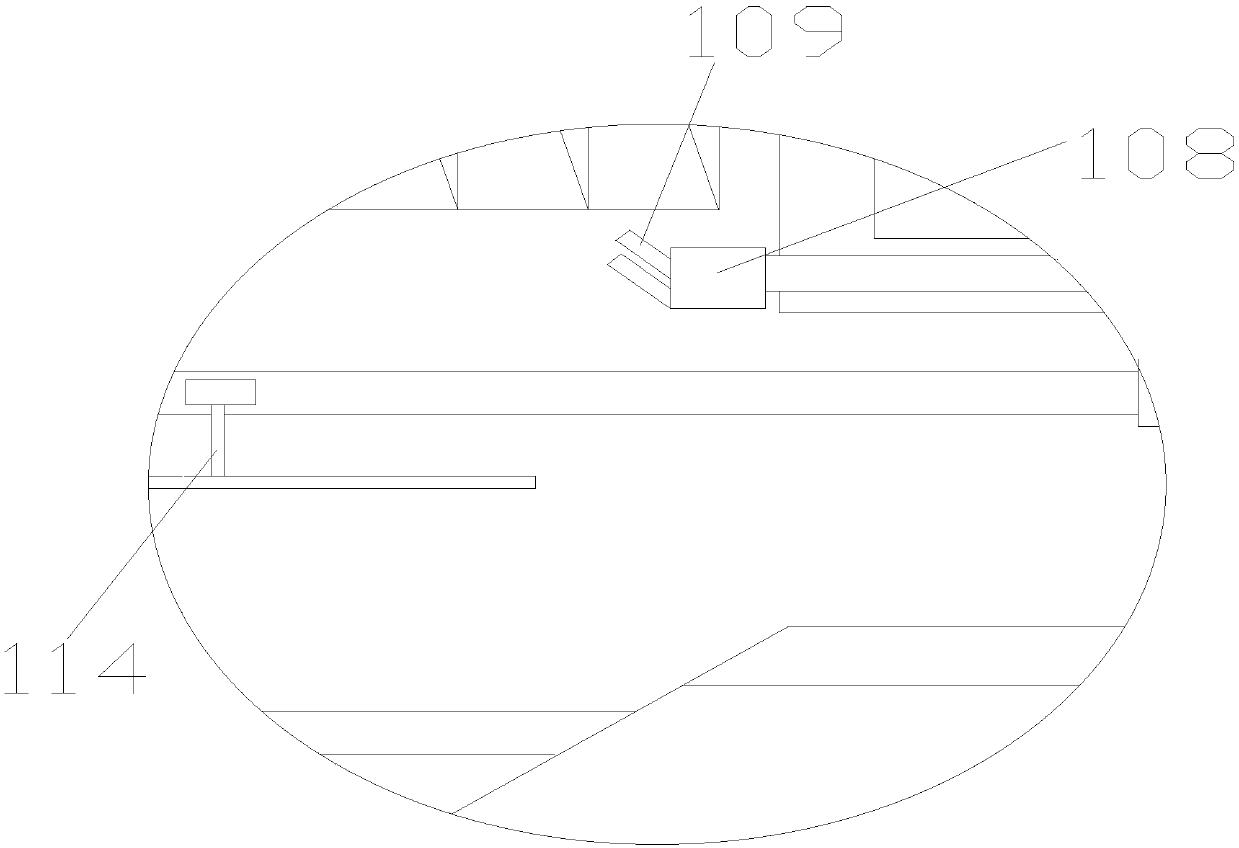

[0029] Described stirring device 1 comprises stirring box 101, the first filter screen 102, the first cutting blade 104, the second cutting blade 105, rotating shaft 103, the second filter screen 117 and cutting assembly 110; Described first filter scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com