Tightening device of insulator replacement device

A tensioner and insulator technology, applied in the direction of overhead lines/cable equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

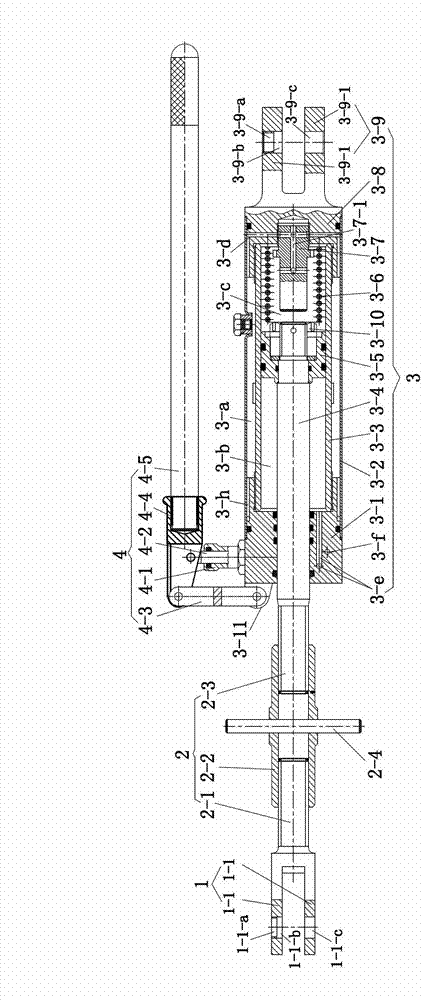

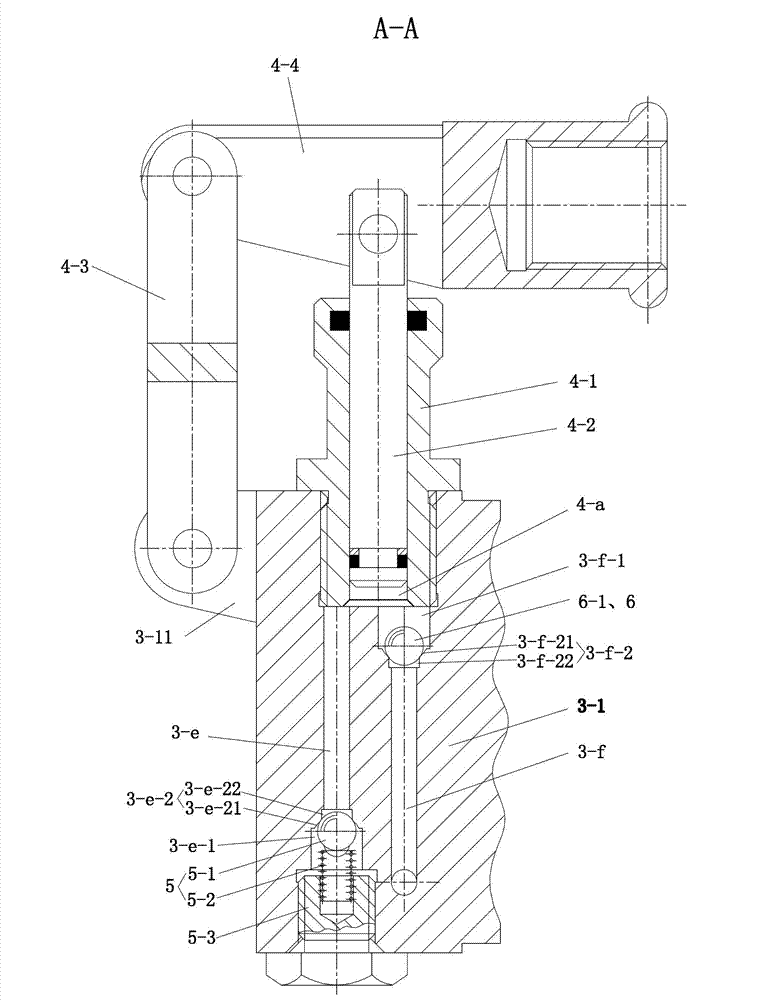

[0025] attached Figures 1 to 4 The tensioner shown includes a yoke 1 , a screw 2 and a hydraulic device 3 . The screw 2 is composed of No. Ⅰ screw 2-1, No. Ⅱ screw 2-3 and double-ended screw sleeve 2-2, and the double-ended screw sleeve 2-2 is connected to the Ⅰ screw 2-1 and the Ⅱ screw. Between 2-3, the thread directions of No. I screw mandrel 2-1 and No. II screw mandrel 2-3 are opposite, and a wrench 2-4 is fixed at the middle part of the double-ended screw sleeve 2-2. The fork joint 1 is connected to the end of No. 1 screw rod 2-1, the piston rod 3-4 of the hydraulic device 3 protrudes from the front end of the cylinder, and the No. 2 screw rod 2-3 is fixedly connected to the piston rod 3-4. It can be integrally processed by No. Ⅱ screw rod 2-3 and piston rod 3-4. The cylinder rear side of the hydraulic device 3 is a fork 3-9, and the hydraulic device 3 is connected with a hand pump 4.

[0026] The cylinder body of hydraulic device 3 is made up of front cylinder body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com