Ternary composite photocatalytic material synthesized by one-step hydrothermal method

A photocatalytic material and ternary composite technology, applied in the field of photocatalytic materials, can solve problems such as complex process, high cost, and impossibility of ternary composite photocatalytic materials, and achieve the effect of simplifying synthesis steps and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

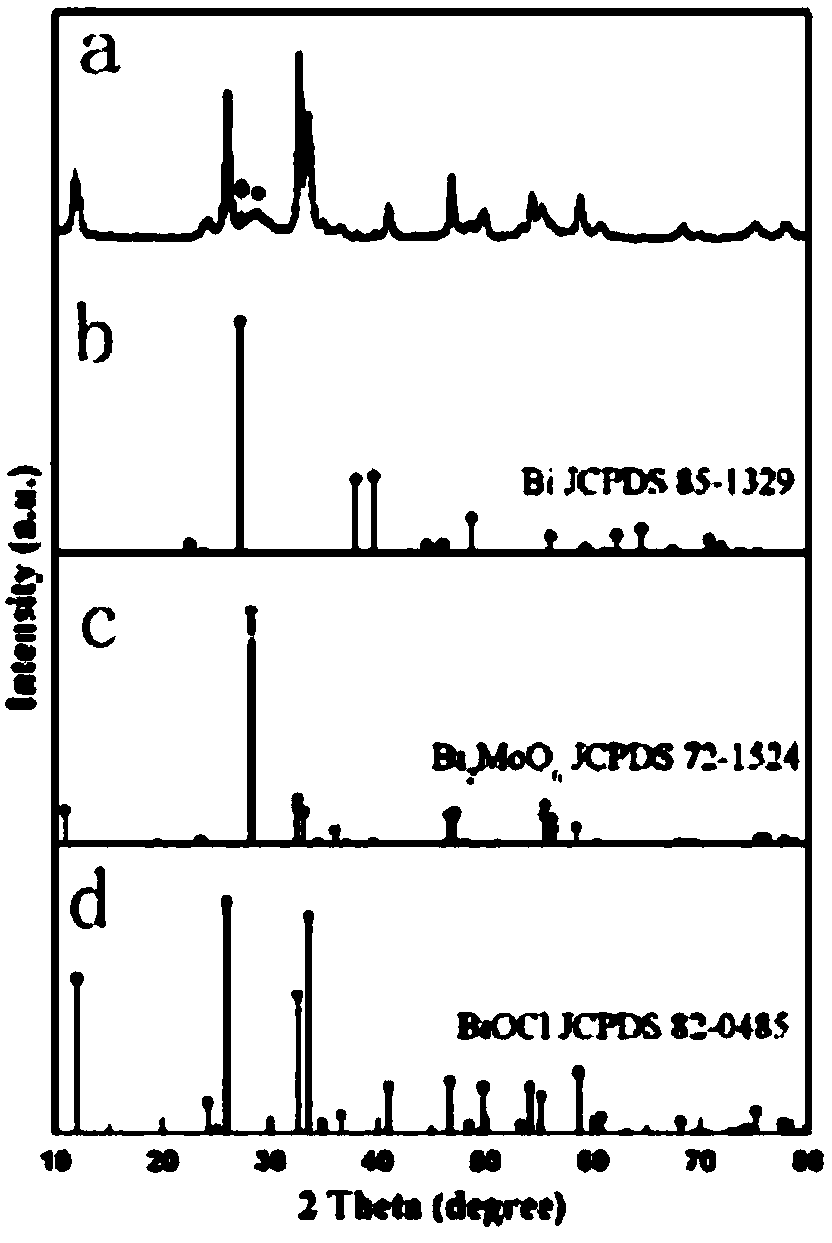

Embodiment 1

[0015] Weigh a certain mass of Bi(NO 3 ) 3 ·5H 2 O (1.4552 g) in 60 mL EG was stirred under a magnetic stirrer for 10 min, then 0.2236 g KCl was added, and stirring was continued for 30 min at room temperature. Then add 0.0242 g Na with stirring 2 MoO 4 2H 2 O, after 30 min of reaction, the reaction solution was transferred to a high-pressure reactor, placed in a homogeneous reactor, and heated to 180°C for 12 h. Then naturally cooled to room temperature, the obtained product was suction filtered, washed with water and ethanol three times, and placed in a drying oven at 60 °C for 12 h. After taking out and pulverizing, the synthetic ternary composite photocatalytic material can be obtained.

Embodiment 2

[0017] Weigh a certain mass of Bi(NO 3 ) 3 ·5H 2 O (1.4552 g) in 60 mL EG was stirred under a magnetic stirrer for 10 min, then 0.0242 g KCl was added, and stirring was continued for 30 min at room temperature. Then add 0.0726 g Na with stirring 2 MoO 4 2H 2 O, after 30 min of reaction, the reaction solution was transferred to a high-pressure reactor, placed in a homogeneous reactor, and heated to 180°C for 12 h. Then naturally cooled to room temperature, the obtained product was suction filtered, washed with water and ethanol three times, and placed in a drying oven at 60 °C for 12 h. After taking out and pulverizing, the synthetic ternary composite photocatalytic material can be obtained.

Embodiment 3

[0019] Weigh a certain mass of Bi(NO 3 ) 3 ·5H 2 O (1.4552 g) in 60 mL EG was stirred under a magnetic stirrer for 10 min, then 0.1210 g KCl was added, and stirring was continued for 30 min at room temperature. Then add 0.1210 g Na with stirring 2 MoO 4 2H 2 O, after 30 min of reaction, the reaction solution was transferred to a high-pressure reactor, placed in a homogeneous reactor, and heated to 180°C for 12 h. Then naturally cooled to room temperature, the obtained product was suction filtered, washed with water and ethanol three times, and placed in a drying oven at 60 °C for 12 h. After taking out and pulverizing, the synthetic ternary composite photocatalytic material can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com