Resource recycling method for waste lithium ion power battery

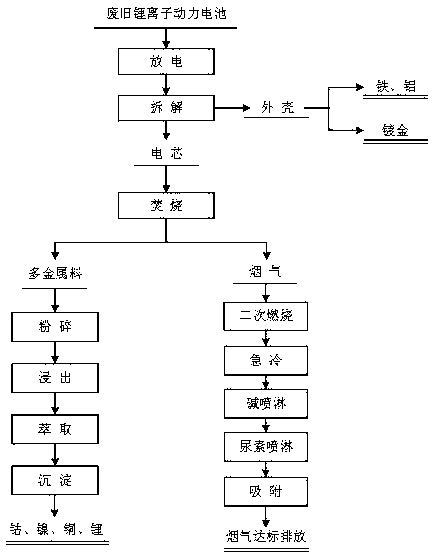

A lithium-ion battery and power battery technology, which is applied in the recycling of waste collectors, etc., can solve the problems of secondary pollution and low metal recovery rate, and achieve the effect of realizing recycling, improving metal recycling rate, and improving environmental protection indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Discharge pretreatment: First, use a special battery puncher to punch holes in the waste lithium-ion power battery. On average, each battery will punch 3-4 holes, and then soak the battery in salt water for discharge treatment. The discharge time is 4 Hours.

[0042] (2) Dismantling: Use a special waste power battery dismantling device to disassemble the shell and gold-plated waste power battery obtained in step (1), and separate to obtain gold-plated, iron or aluminum shells, and batteries. They are respectively used for the subsequent recovery of gold, iron and aluminum, and the batteries are used for subsequent recycling.

[0043] (3) Incineration: Use a converter to incinerate the cells of the waste lithium-ion power battery. The incineration temperature is controlled at 600°C and the incineration time is maintained for 60 minutes to obtain polymetallic materials and flue gas.

[0044] (4) Pulverization: The polymetallic material obtained in step (3) was pulver...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com