A shield tunnel lining segment and its reinforcement method

A technology for lining segments and shield tunnels, applied in tunnel lining, tunnel, wellbore lining, etc., can solve the problems of insufficient deformation restraint control ability, unsatisfactory joint reinforcement effect, and difficulty in preventing deformation in advance, so as to reduce the joint direction. The effect of outward opening, balancing safety and economy, and ensuring the safety of tunnel operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

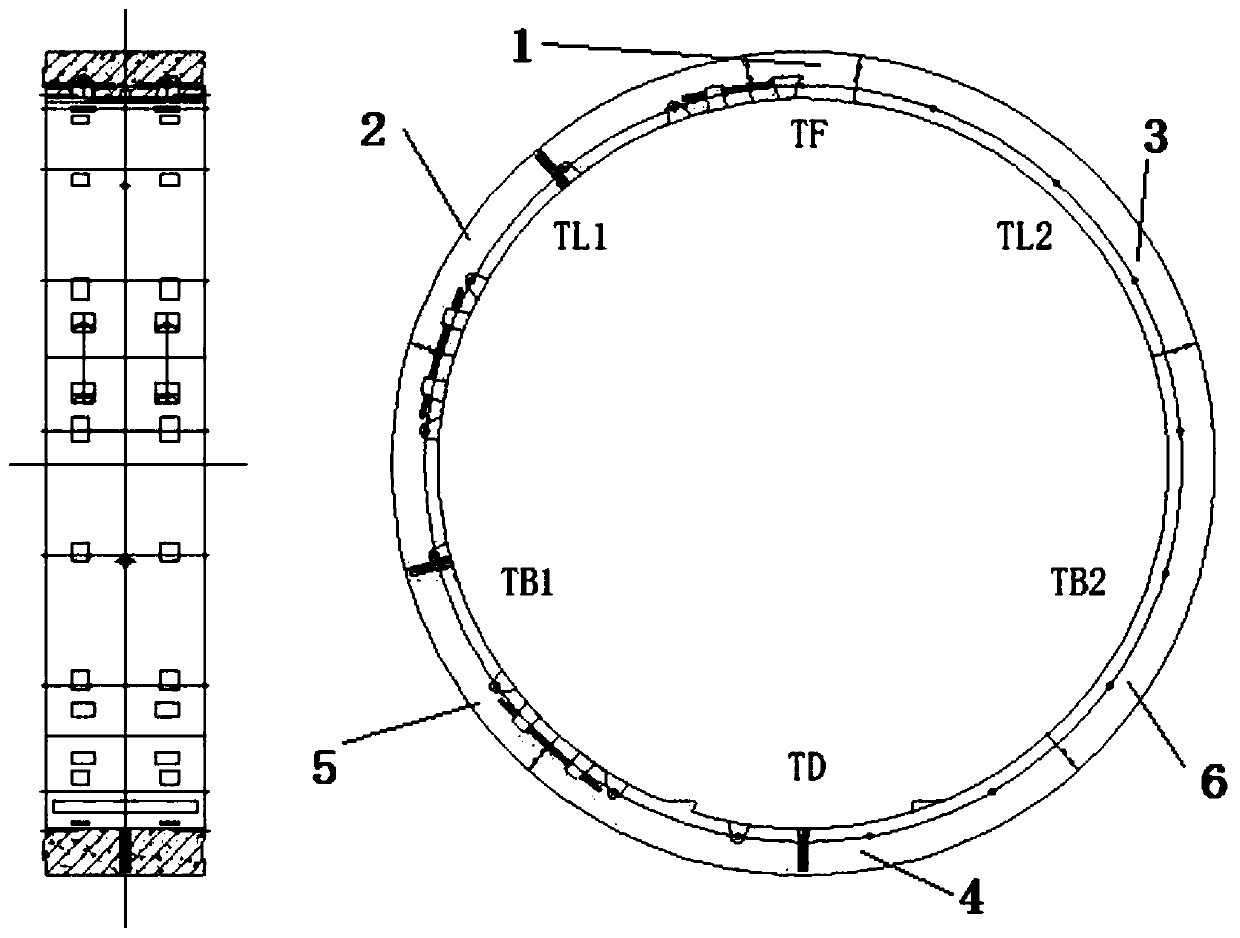

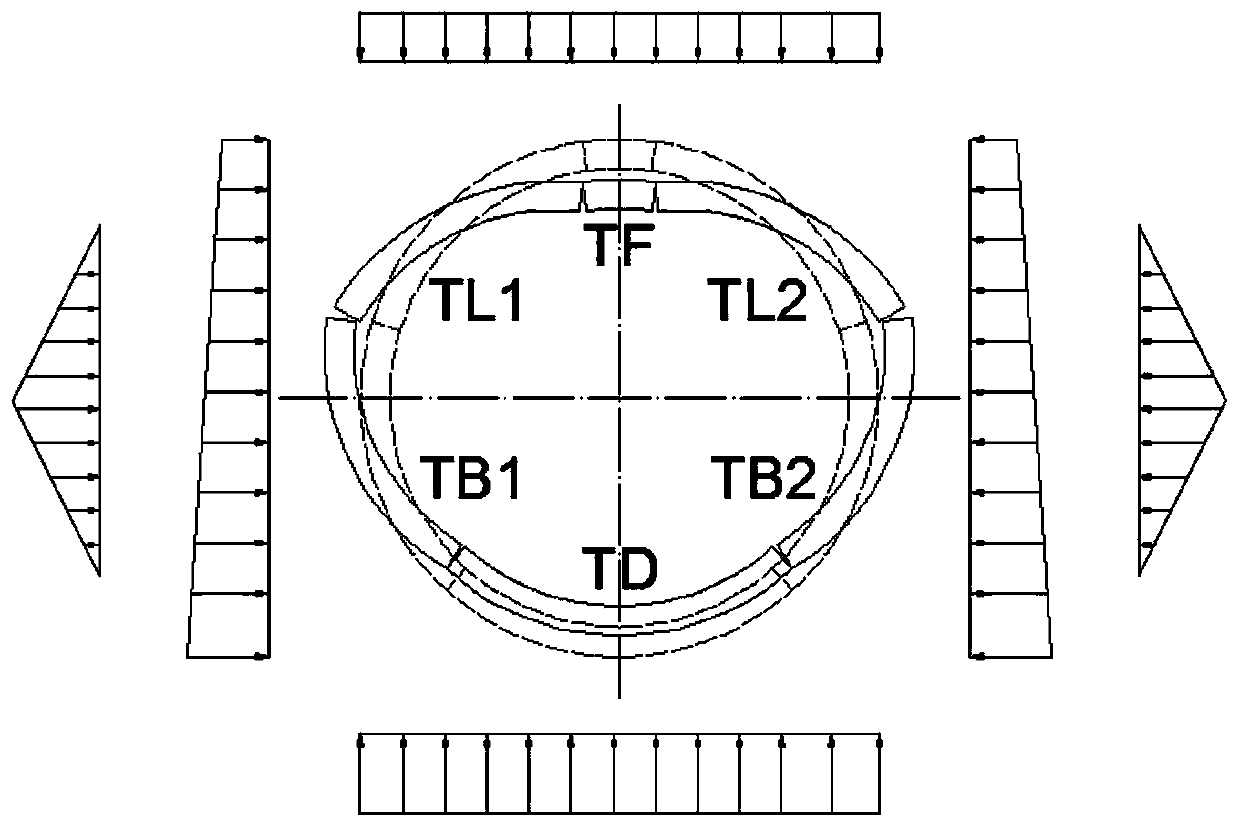

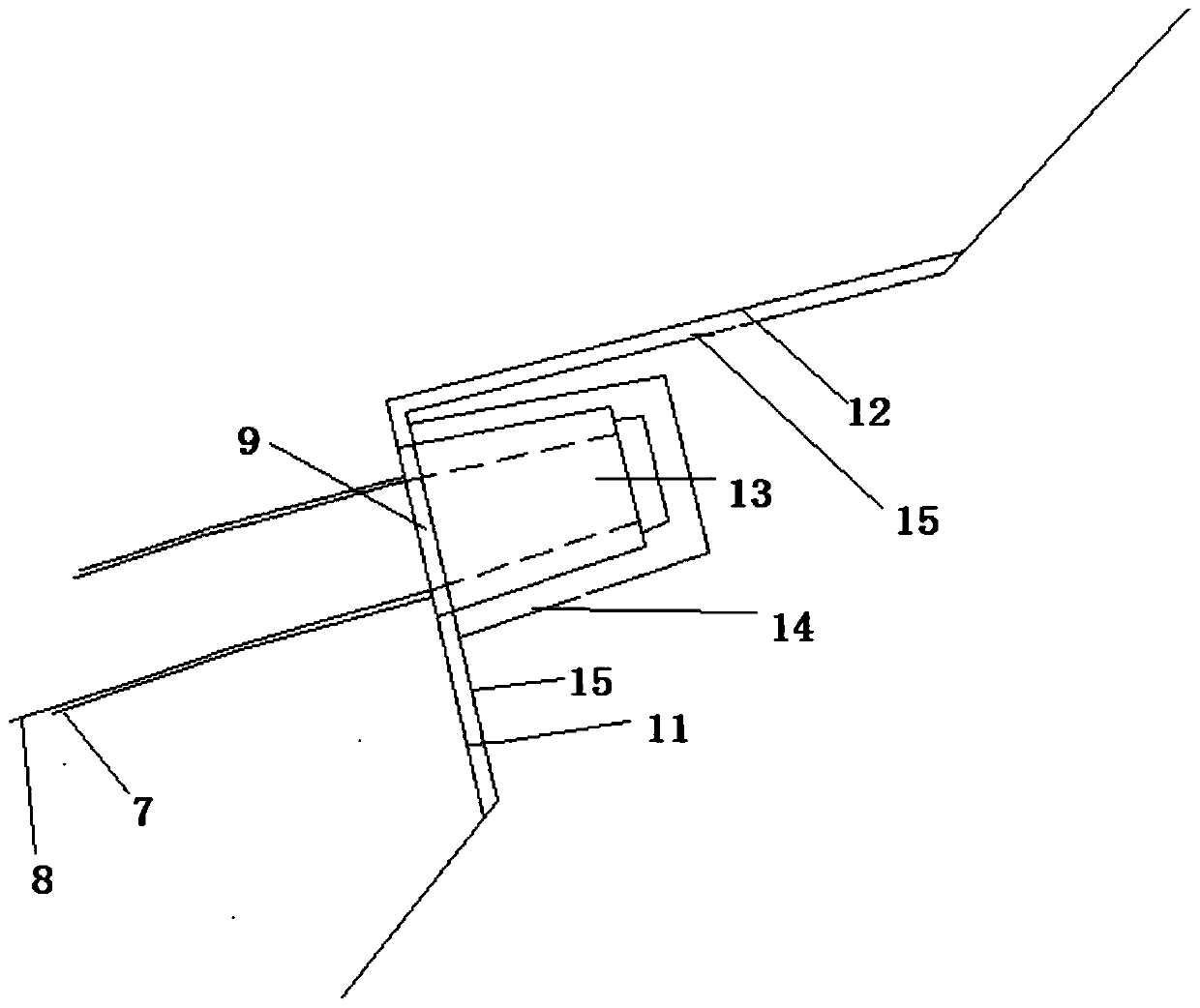

[0058] Such as Figure 7 Said, the shield tunnel lining segment joint stiffness enhancement method of the present invention comprises the following steps:

[0059] Collect basic tunnel information (dimensions, loads), calculate short-term and long-term tunnel loads, internal forces, and deformations, determine the near- and long-term tension values of the steel strand 8, determine the type, strength, and diameter of the steel strand 8, and design segments ( Diameter, thickness, bolt hole position), determine the position, radian, and aperture of the steel strand tunnel 7, the position and size of the operating hole, perform segment prefabrication, tunnel construction, assemble new prefabricated lining segments, and align the steel strand tunnel 7. The steel strands 8 are crossed between adjacent segments.

[0060] Case 1:

[0061] If the ground load borne by the tunnel structure is small, the probability of later ground variation and ground overload is low, and the overall...

Embodiment 2

[0065] Such as Figure 8 and Figure 9 As shown, the shield tunnel lining segment of the present invention is provided with a steel belt ring 16, and the steel belt ring 16 includes a flat steel belt 17 and a pre-tightening joint 18; the steel belt ring 16 is wound around the lining segment external. The steel belt ring 16 is fixed inside the shield shell, and is attached to the inner wall of the shield shell, and a steel belt fixing device is arranged in the shield shell. The fixing device is located in the middle of the lining segment and is a fixing groove or a fixing buckle structure.

[0066] Such as Figure 10 Said, the overall tunnel reinforcement method of the present invention includes the following steps:

[0067] 1) Process the steel belt ring 16 according to the construction requirements, and perform anti-rust treatment;

[0068] 2) Transport the steel belt ring 16 into the shield shell in a strip shape;

[0069] 3) The two ends of the flat steel strip 17 are...

Embodiment 3

[0076] When the shield tunnel lining segment of the present invention is reinforced, the respective reinforcement methods in the above-mentioned embodiment 1 and embodiment 2 are combined, and act on the same shield tunnel lining segment reinforcement at the same time. Tunnel reinforcement and lateral deformation elimination can be carried out through simple operations, reducing the outward opening of joints; during construction, there is no need to relocate various pipelines in the tunnel, no need to add additional processes and materials, and basically does not affect the operation of the tunnel. This method also has the dual effect of simultaneously satisfying the tunnel reinforcement prevention before deformation and the elimination of deformation after deformation, preventing the damage caused by excessive lateral deformation and ensuring the safety of tunnel operation. Two schemes of grouting and non-grouting in the steel strand tunnel are designed, which can flexibly ada...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com