Soil heavy metal pollution environmental protection repair agent, soil heavy metal environmental protection repair method

A technology of heavy metals and remediation agents, applied in the restoration, fermentation, agriculture and other directions of polluted soil, can solve the problems of long-term environment, pollutants, heavy metals cannot be degraded by microorganisms, etc., to promote root growth, improve soil fertility, and improve plants. Effects of root microbial environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

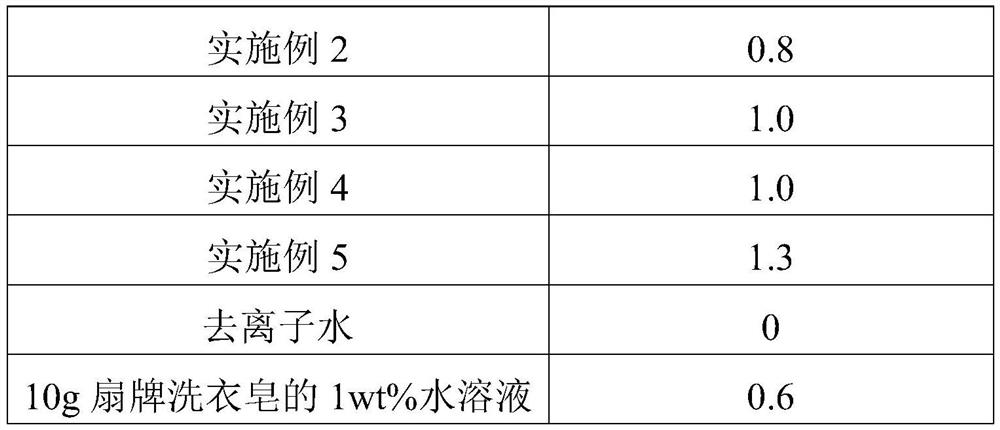

Embodiment 1

[0031] Embodiment 1: the preparation of rhamnolipid biosurfactant

[0032] Pseudomonas aeruginosa CCTCC AB 2013184 was added to the fermentation medium at an inoculum size of 3% (V / V), and cultured on a shaker at 37°C at a speed of 280 rpm for 90 hours to obtain a fermentation broth;

[0033] The composition of the fermentation medium is olive oil 60g / L, sodium nitrate 8g / L, sodium chloride 1.0g / L, potassium chloride 1.0g / L, calcium chloride 0.1g / L, KH 2 PO 4 12H 2 O 3.5g / L, magnesium sulfate 0.25g / L, FeSO 4 ·7H 2 O 0.001g / L, the balance is water, pH6.6.

[0034] The fermentation broth was incubated at 120°C for 30 minutes, then cooled to 40°C, centrifuged at 10,000 rpm for 5 minutes to remove bacterial fragments, and the supernatant was extracted with an equal volume of ethyl acetate, and then used a rotary evaporator Distill under reduced pressure to control the rhamnolipid content to 10g / L to obtain the bio-environmental friendly surfactant of the present invention.

Embodiment 2

[0035] Embodiment 2: the preparation of rhamnolipid biosurfactant

[0036] Pseudomonas aeruginosa CCTCC AB 2013184 was added to the fermentation medium at an inoculum size of 3% (V / V), and cultured on a shaker at 37°C at a speed of 280 rpm for 90 hours to obtain a fermentation broth;

[0037] The composition of the fermentation medium is 60g / L of safflower seed oil, 8g / L of sodium nitrate, 1.0g / L of sodium chloride, 1.0g / L of potassium chloride, 0.1g / L of calcium chloride, KH 2 PO 4 12H 2 O 3.5g / L, magnesium sulfate 0.25g / L, FeSO 4 ·7H 2 O 0.001g / L, the balance is water, pH6.6.

[0038] The fermentation broth was incubated at 120°C for 30 minutes, then cooled to 40°C, centrifuged at 10,000 rpm for 5 minutes to remove bacterial fragments, and the supernatant was extracted with an equal volume of ethyl acetate, and then used a rotary evaporator Distill under reduced pressure to control the rhamnolipid content to 10g / L to obtain the bio-environmental friendly surfactant of t...

Embodiment 3

[0039] Embodiment 3: the preparation of rhamnolipid biosurfactant

[0040] Pseudomonas aeruginosa CCTCC AB 2013184 was added to the fermentation medium at an inoculum size of 3% (V / V), and cultured on a shaker at 37°C at a speed of 280 rpm for 90 hours to obtain a fermentation broth;

[0041] The composition of the fermentation medium is olive oil 20g / L, safflower seed oil 40g / L, sodium nitrate 8g / L, sodium chloride 1.0g / L, potassium chloride 1.0g / L, calcium chloride 0.1g / L 、KH 2 PO 4 12H 2 O 3.5g / L, magnesium sulfate 0.25g / L, FeSO 4 ·7H 2 O0.001g / L, the balance is water, pH6.6.

[0042] The fermentation broth was incubated at 120°C for 30 minutes, then cooled to 40°C, centrifuged at 10,000 rpm for 5 minutes to remove bacterial fragments, and the supernatant was extracted with an equal volume of ethyl acetate, and then used a rotary evaporator Distill under reduced pressure to control the rhamnolipid content to 10g / L to obtain the bio-environmental friendly surfactant of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com