Cleaning agent for acidic pollutants in paper-making wastewater

A technology for papermaking wastewater and pollutants, applied in water/sewage treatment, process wastewater treatment, water/sludge/sewage treatment, etc., can solve problems such as destruction of ecological balance, death of plankton and fish, increase of toxic substances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

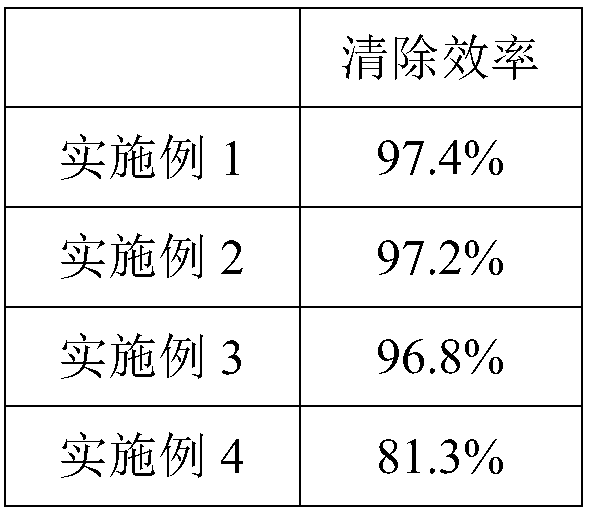

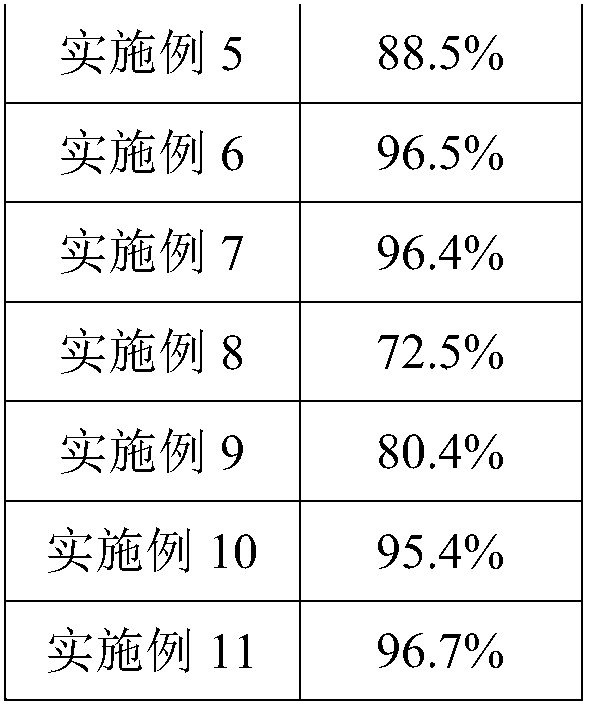

Examples

Embodiment 1

[0057] The cleaning agent for acidic pollutants in papermaking wastewater, in parts by weight, its raw materials include: 8 parts of buttercup extract, 20 parts of Coptis chinensis extract, 4 parts of ephedra extract, 10 parts of shiitake mushroom extract, 10 parts of Anemarrhena anemarrhena extract, 4 parts of Alice extract, 150 parts of water.

[0058] The preparation method of the ranunculus extract is as follows: take 400g of ranunculus, grind it into powder, add 2000mL of acetone, let it stand for 12h, filter, evaporate the filtrate to dryness, add 200g of honeysuckle powder and 2000mL of anhydrous ether, heat and reflux for 5h, filter, Add saturated NaHCO to the filtrate 3 Solution, liquid separation, collect the ether layer, then add 200mL 10wt% NaOH solution, separate the liquid, collect the water layer, add hydrochloric acid until no precipitation occurs, add 200mL anhydrous ether, separate the liquid, collect the ether layer, and then evaporate the solvent to dryness...

Embodiment 2

[0065] The cleaning agent for acidic pollutants in papermaking wastewater, in parts by weight, its raw materials include: 8 parts of buttercup extract, 20 parts of Coptis chinensis extract, 4 parts of ephedra extract, 10 parts of shiitake mushroom extract, 10 parts of Anemarrhena anemarrhena extract, 4 parts of cockroach extract, 6 parts of turmeric extract, 3 parts of Panax ginseng extract, 150 parts of water.

[0066] The preparation method of the ranunculus extract is as follows: take 400g of ranunculus, grind it into powder, add 2000mL of acetone, let it stand for 12h, filter, evaporate the filtrate to dryness, add 200g of honeysuckle powder and 2000mL of anhydrous ether, heat and reflux for 5h, filter, Add saturated NaHCO to the filtrate 3 Solution, liquid separation, collect the ether layer, then add 200mL 10wt% NaOH solution, separate the liquid, collect the water layer, add hydrochloric acid until no precipitation occurs, add 200mL anhydrous ether, separate the liquid,...

Embodiment 3

[0075] The cleaning agent for acidic pollutants in papermaking wastewater, in parts by weight, its raw materials include: 8 parts of buttercup extract, 20 parts of Coptis chinensis extract, 4 parts of ephedra extract, 10 parts of shiitake mushroom extract, 10 parts of Anemarrhena anemarrhena extract, 4 parts of cockroach extract, 6 parts of turmeric extract, 3 parts of Panax ginseng extract, 150 parts of water.

[0076] The preparation method of the ranunculus extract is as follows: take 400g of ranunculus, grind it into powder, add 2000mL of acetone, let stand for 12h, filter, evaporate the filtrate to dryness, add 2000mL of anhydrous ether, heat and reflux for 5h, filter, and add saturated NaHCO 3 Solution, liquid separation, collect the ether layer, then add 200mL 10wt% NaOH solution, separate the liquid, collect the water layer, add hydrochloric acid until no precipitation occurs, add 200mL anhydrous ether, separate the liquid, collect the ether layer, and then evaporate t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com