Method for producing hot-rolled strip steel with thickness being smaller than or equal to 1.2 mm through thin slab continuous casting and rolling

A technology of thin slab continuous casting and hot-rolled strip steel, which is applied in the field of thin slab continuous casting and rolling to produce hot-rolled strip steel with a thickness of ≤1.2mm, which can solve problems affecting rolling stability, head folding and rolling breakage, etc. Achieve the effects of avoiding steel scrap accidents, improving rolling stability, and improving strip threading stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

[0035] A method for producing hot-rolled steel strips with a thickness of ≤1.2 mm by continuous casting and rolling of thin slabs, comprising the following steps:

[0036] 1) Steelmaking: use converter smelting, refining outside the furnace and continuous casting into slabs, and control the thickness of the continuous casting slabs to 52-55mm;

[0037] 2) Soaking: Soak the continuous casting slab, and control the temperature of the continuous casting slab to be 1200-1220°C;

[0038] 3) Descaling: Perform high-pressure descaling on the soaked continuous casting slab;

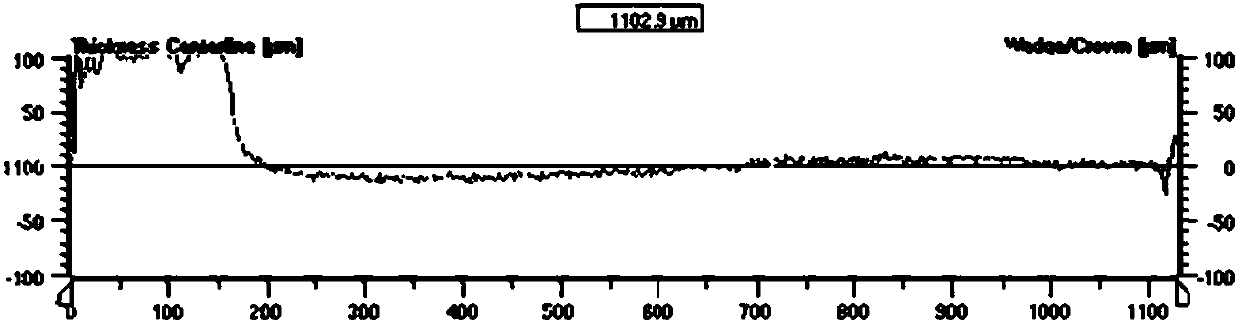

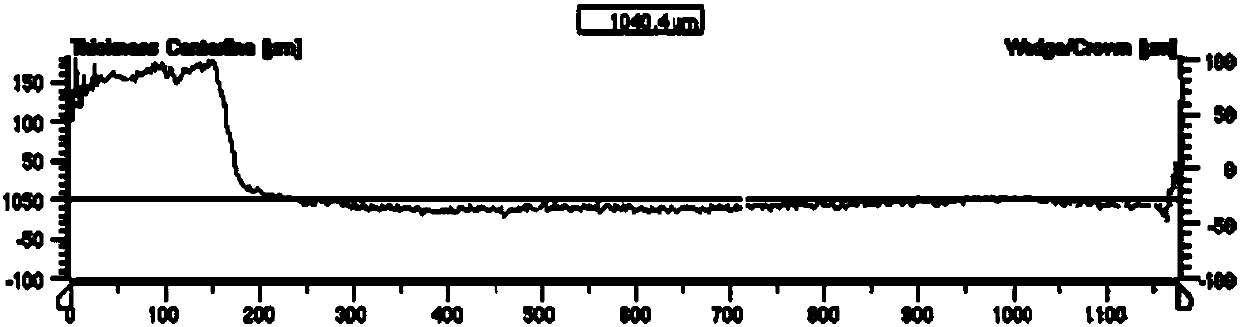

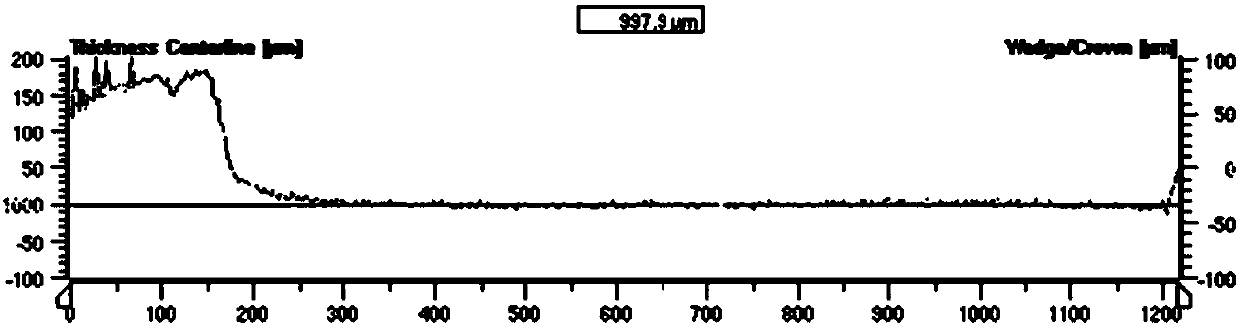

[0039] 4) Finish rolling: The continuous casting slab enters the finish rolling unit, and the cooling water in the roll gap of the F1-F4 stands is controlled to be opened after the head of the strip steel passes through the stands. The reduction is 50-200μm, the dynamic variable-size reduction sequence is 80-150m from the strip head, the target strip crown is set at 50-55μm, the final rolling temperature is 840-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com