Coupling

A technology for connecting components and connecting components, applied in the direction of couplings, rigid shaft couplings, mechanical equipment, etc., can solve the problems of prolonged maintenance operations, production impact, etc., and achieve the effect of reducing complexity and difficulty and reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

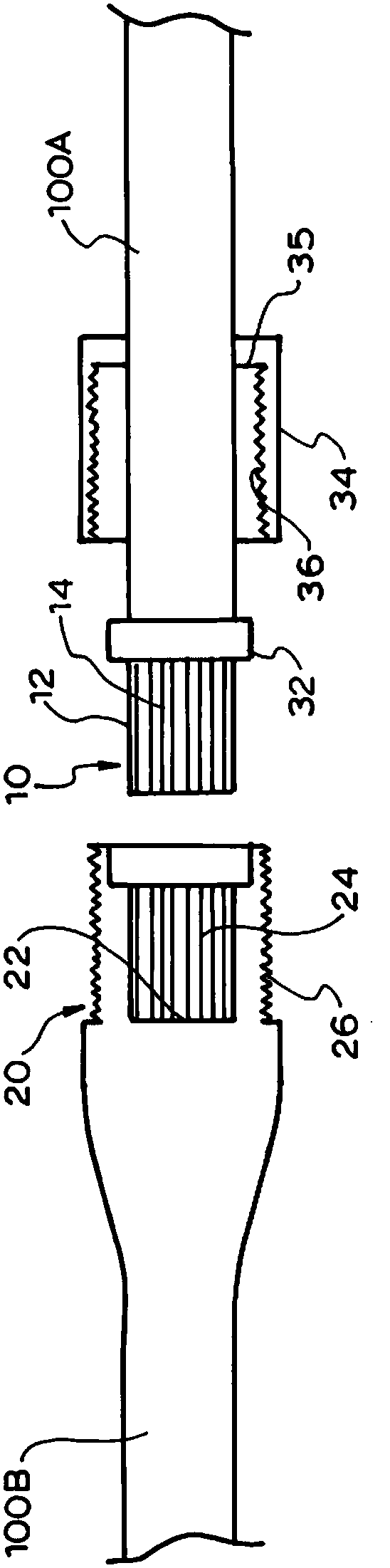

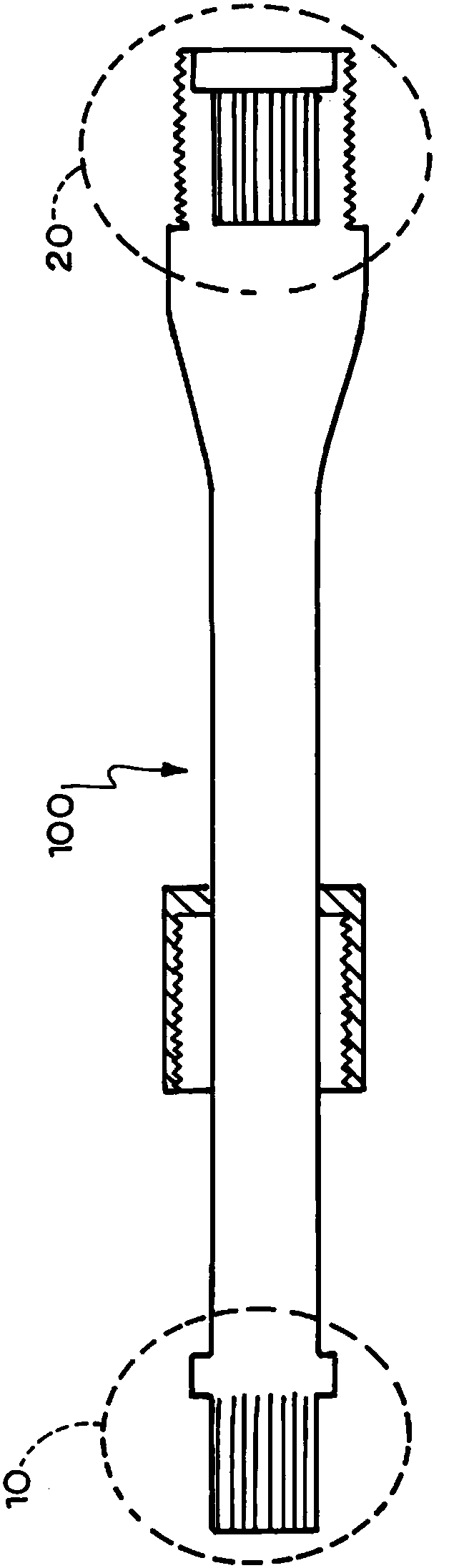

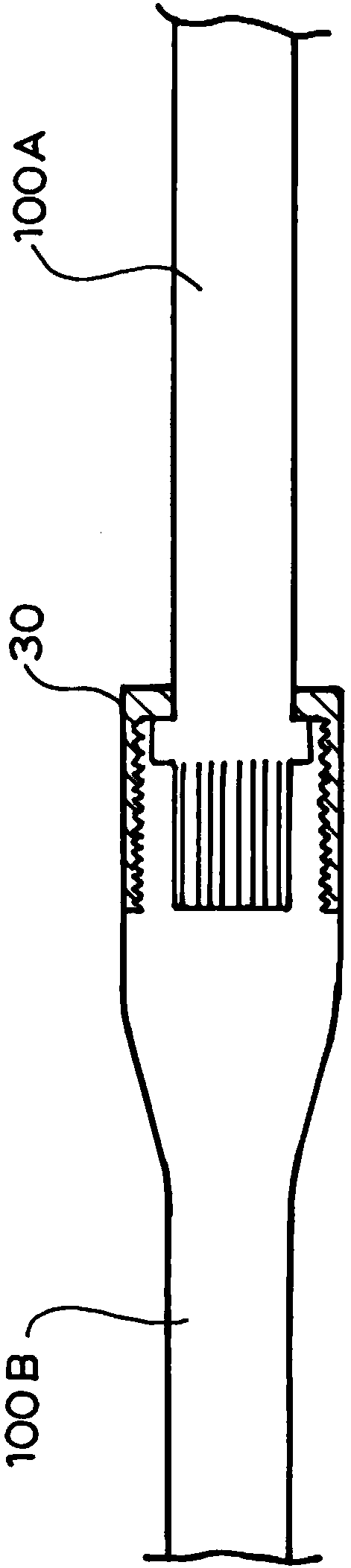

[0043] see Figure 1 to Figure 6 , the first embodiment of the present invention is provided in the form of a rod assembly, specifically a sucker rod 100 comprising a male connection end 10 and a female connection end 20 . A plurality of sucker rods 100, such as a first sucker rod 100A, can be achieved by connecting the male connection end 10 of the first sucker rod 100A to the female connection end 20 of another sucker rod (such as a second sucker rod 100B) or matched to connect the second sucker rod 100B in series. The male connection end 10 includes a generally cylindrical male connection portion 12 matingly received in a cavity 22 to engage the male connection end 10 of the sucker rod 100A with the female connection end 20 of the sucker rod 100B. The male connection part 12 is provided with a plurality of engagement ribs in the form of splines 14 extending in the direction of the longitudinal axis of the rod 100 . The cavity 22 in the female connector 20 is provided in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com