Distributed predictive control method for multi-motor cutter system of heading machine

A technology of predictive control and roadheader, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problems of optimization time, structural robustness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

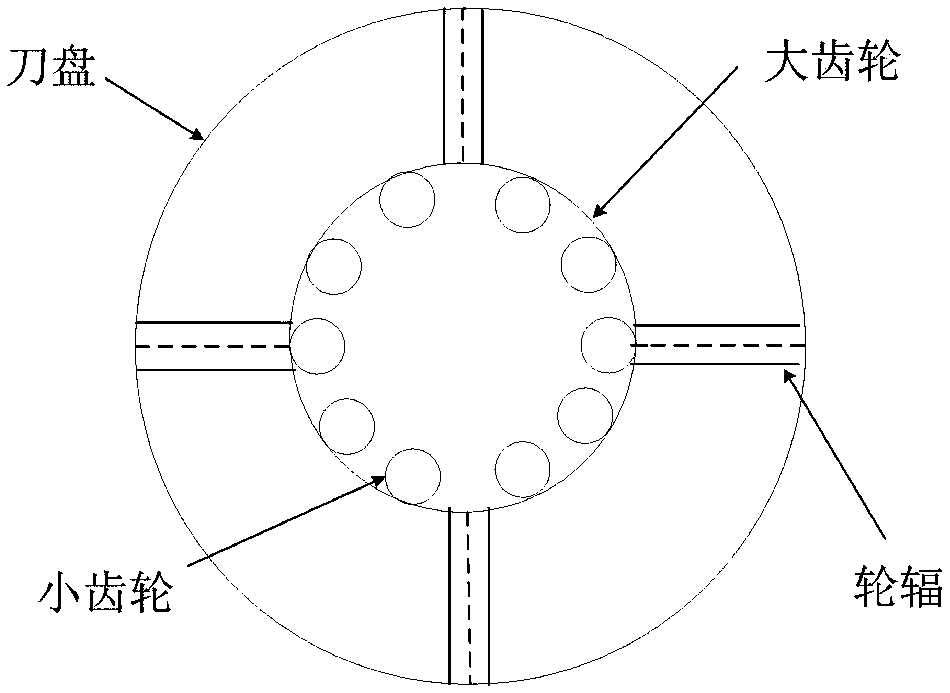

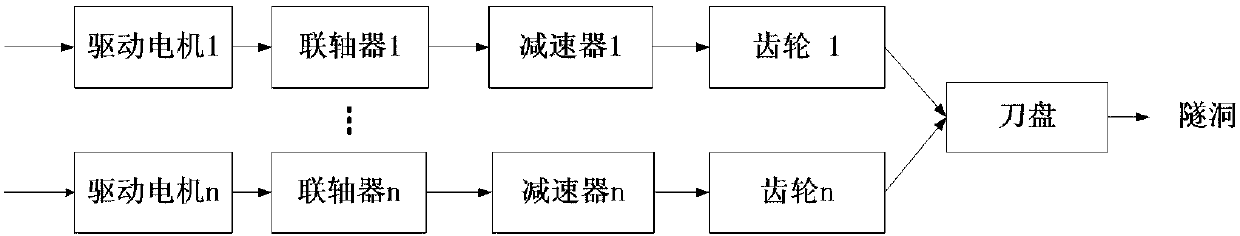

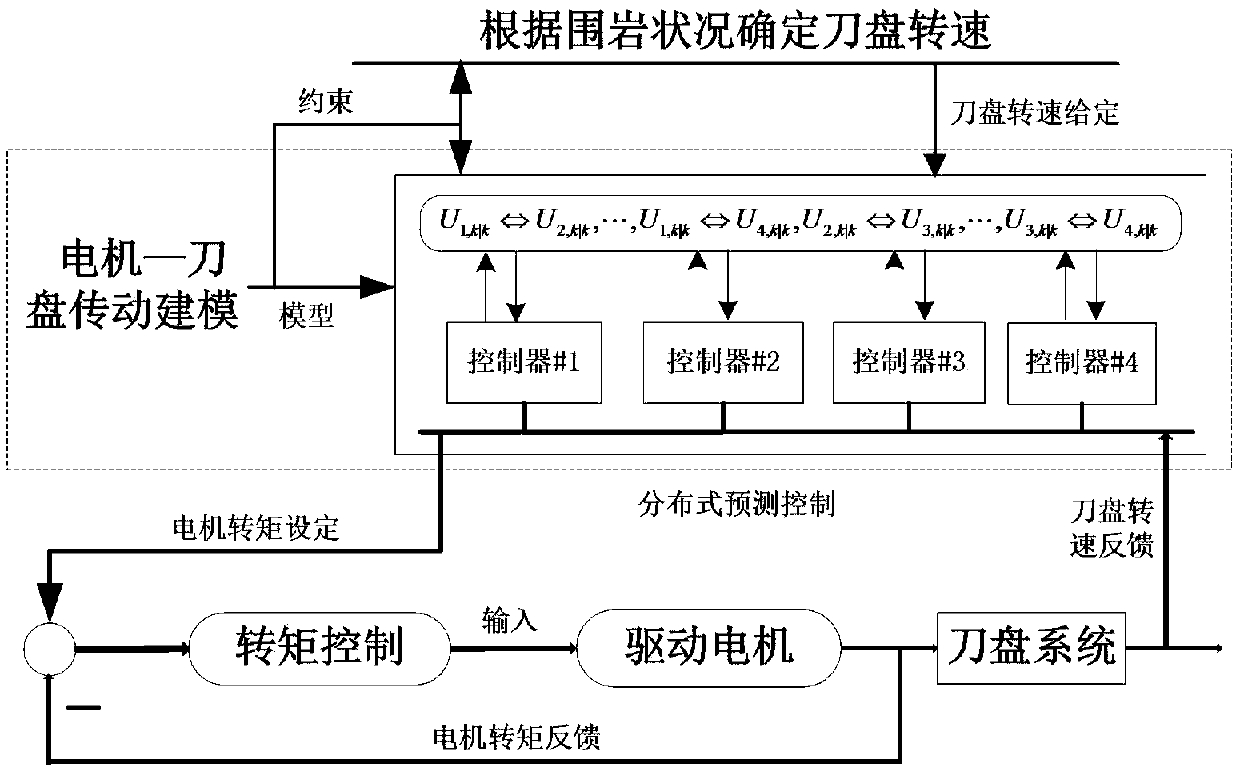

[0093] Distributed predictive control is mainly to solve the optimization time and structural robustness of centralized control algorithms in complex industrial processes. It is an extension and expansion of traditional centralized control algorithms. In terms of reliability, flexibility and fault tolerance Both have advantages over traditional centralized control. The distributed predictive control technology of the roadheader multi-motor cutterhead system divides the roadheader cutterhead system into multiple areas, and uses the distributed predictive control method to optimize the design of the motor torque in each area, mainly involving the following types of technologies: Mechanical system partition modeling, distributed predictive control design, motor vector control, etc.

[0094] At present, with the continuous improvement of modern technology and communication technology, the control mode of complex distributed systems is gradually changing to networked distributed co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com