Automatic testing robot system for capacitive/magnetic pen tablet electronic equipment

A robot system and electronic equipment technology, applied in the direction of applying repetitive force/pulsation force to test the strength of materials, instruments, and measuring electricity, can solve problems such as human errors and losses, achieve high safety performance, save labor costs, and improve Effect of Test Efficiency and Accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] Such as figure 1 As shown, this embodiment provides an automatic test robot system for capacitor / magnetic pen tablet electronic equipment, which is composed of a host computer, a six-axis collaborative robot, an electronic scale, and a control cabinet;

[0060] Among them, the PC is the upper computer and the control host;

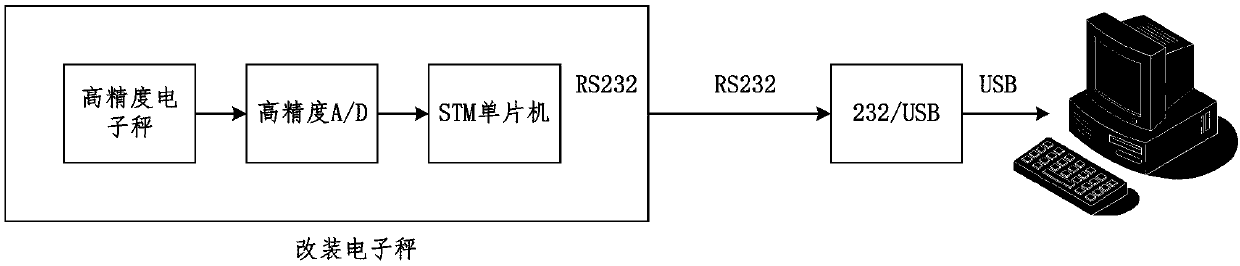

[0061] The electronic scale is a modified lower computer, such as image 3 As shown, the modified electronic scale integrates the electronic scale of the PCB board, which collects the pressure-sensitive data through the PCB board, puts the electronic screen to be tested on the high-precision electronic scale, and uses the PCB board to collect the pressure-sensitive signal.

[0062] The six-axis collaborative robot is controlled by the host computer and driven by the control cabinet, and the test is completed by installing an automatic test program and UI. Generally, the wust-1 series six-axis collaborative robot is used for automatic testing of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com