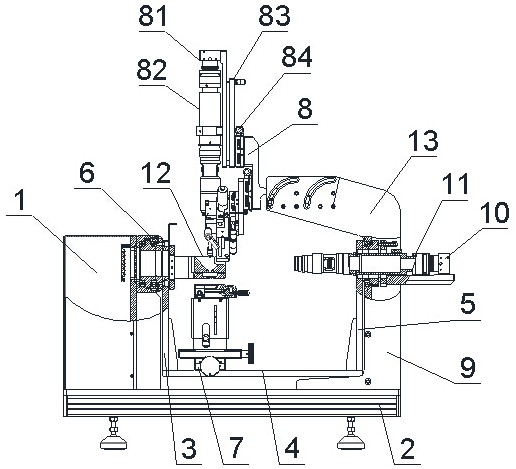

A 3D contact angle testing device and method using a polygonal mirror to refract the light path

A technology of reversing the optical path and testing device, applied in the direction of measurement device, instrument, surface/boundary effect, etc., can solve the problems of poor image synchronization, complicated operation, and inability to measure the contact angle comprehensively and accurately.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

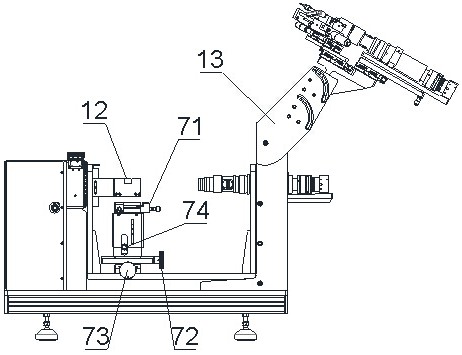

Embodiment 1

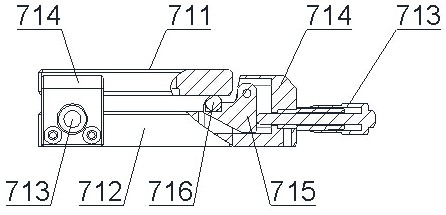

[0057] Such as Figure 4 and Figure 6 As shown, the prism 3D contact angle lens 12 is a 180 degree 3D contact angle lens, and the 180 degree 3D contact angle lens includes two second rectangular prisms 124 and two mounting frames 122, and the two mounting frames 122 are respectively fixed on Two second rectangular prisms 124 are oppositely arranged between the two mounting frames 122 on the opposite sides of the mounting seat 121 so that the slopes of the two are facing and the front ends are against each other. The front ends of the second rectangular prisms 124 are respectively opened and installed The same semicircular hole of seat 121 central through hole diameter, is provided with triangular light-shielding block between two second rectangular prisms 124, and the first rectangular prism 123 is a total inverse rectangular prism, the first rectangular prism 123 oblique faces downward, two rectangular faces They are respectively arranged in the through holes of the mountin...

Embodiment 2

[0062] Such as Figure 7 and Figure 8 As shown, the multi-prism 3D contact angle lens 12 is a 360-degree 3D contact-angle lens, and the 360-degree 3D contact-angle lens includes several first right-angle prisms 123 and a second right-angle prism 124, and also includes a second right-angle prism fixing frame 125, the second rectangular prism 124 is a total inversion rectangular prism, the first rectangular prism 123 is a transflective rectangular prism, the second rectangular prism holder 125 is fixed on the mount 121, and the second rectangular prism 124 is fixed Be positioned at the top of the first right-angled prism 123 on the second right-angled prism holder 125, the slope of the second right-angled prism 124 is downward, two right-angled surfaces are parallel with vertical plane and horizontal plane respectively, the slope of the first right-angled prism 123 is upward, The two right-angled planes are respectively arranged in the through hole of the mounting base 121 par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com