Torque detecting device and detecting method used in tractor gearbox inner cavity

A technology of torque detection and transmission, which is applied in the field of tractors, can solve the problems that it is difficult to ensure the constant power of the engine, the output of constant speed, and the difficulty of ensuring constant power output due to frustration, so as to achieve accurate and reliable detection data, compact structure, and constant power output Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

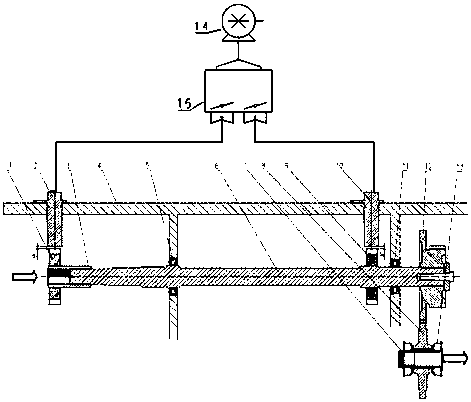

[0025] The present invention will be further described below in conjunction with the accompanying drawings. Such as Figure 1~5 Shown: a torque detection device for the inner cavity of the tractor gearbox, mainly including: main box signal plate 1, main box detection sensor 2, main box signal plate spline sleeve 3, gearbox housing 4, front bearing 5 , elastic signal shaft 6, power output shaft 7, power output driven gear 8, auxiliary box signal plate 9, auxiliary box detection sensor 10, rear bearing 11, power output driving gear 12, power output shaft bearing 13, engine 14, control Device 15 and other parts.

[0026] The main box signal plate spline sleeve 3 is connected with the tractor clutch through the spline shaft; the main box signal plate spline sleeve 3 is connected with the main box signal plate 1 with interference fit; the elastic signal shaft 6 is connected with the auxiliary box signal plate 9 with interference fit . The power take-off shaft 7 is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com