Double-ring stepless speed changer

A technology of continuously variable transmission and continuously variable transmission, which is applied in the direction of transmission parts, friction transmission devices, components with teeth, etc., and can solve the problems of high processing and lubrication requirements for parts, occasions that cannot be applied comprehensively, and high manufacturing precision requirements, etc. problem, achieve the effect of small space requirement, low maintenance cost and continuous transmission ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

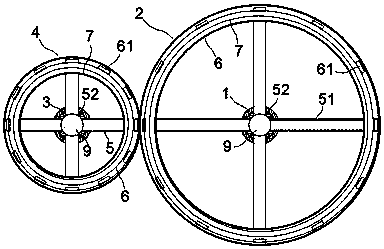

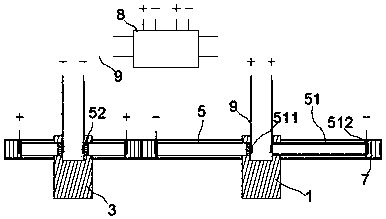

[0019] exist figure 1 , figure 2 In the shown embodiment, the double-ring continuously variable transmission includes a casing, a drive shaft 1 and a transmission shaft 3, and the drive shaft 1 is driven to rotate by a drive motor;

[0020] The drive shaft 1 and the transmission shaft 3 are arranged in parallel, and a drive ring 2 is arranged coaxially outside the drive shaft 1. The drive ring 2 and the drive shaft 1 are connected by a telescopic rod structure 5, and the telescopic rod structure 5 is arranged in a rotationally symmetrical row. It is arranged in the circumferential direction of the drive shaft 1; a transmission ring 4 is coaxially arranged outside the transmission shaft 3, and the transmission ring 4 and the transmission shaft 3 are connected by a telescopic rod structure 5, and the telescopic rod structure 5 is arranged in a rotationally symmetrical manner In the circumferential direction of the transmission shaft 3; the drive ring 2 and the transmission rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com