Connection construction and construction method of assembled shear wall panels and wall panels

A prefabricated shear wall technology, applied in building structures, walls, building components, etc., can solve the problems of complex construction, low efficiency, inconvenient disassembly and assembly, and achieve the effects of convenient construction, clear force transmission, and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

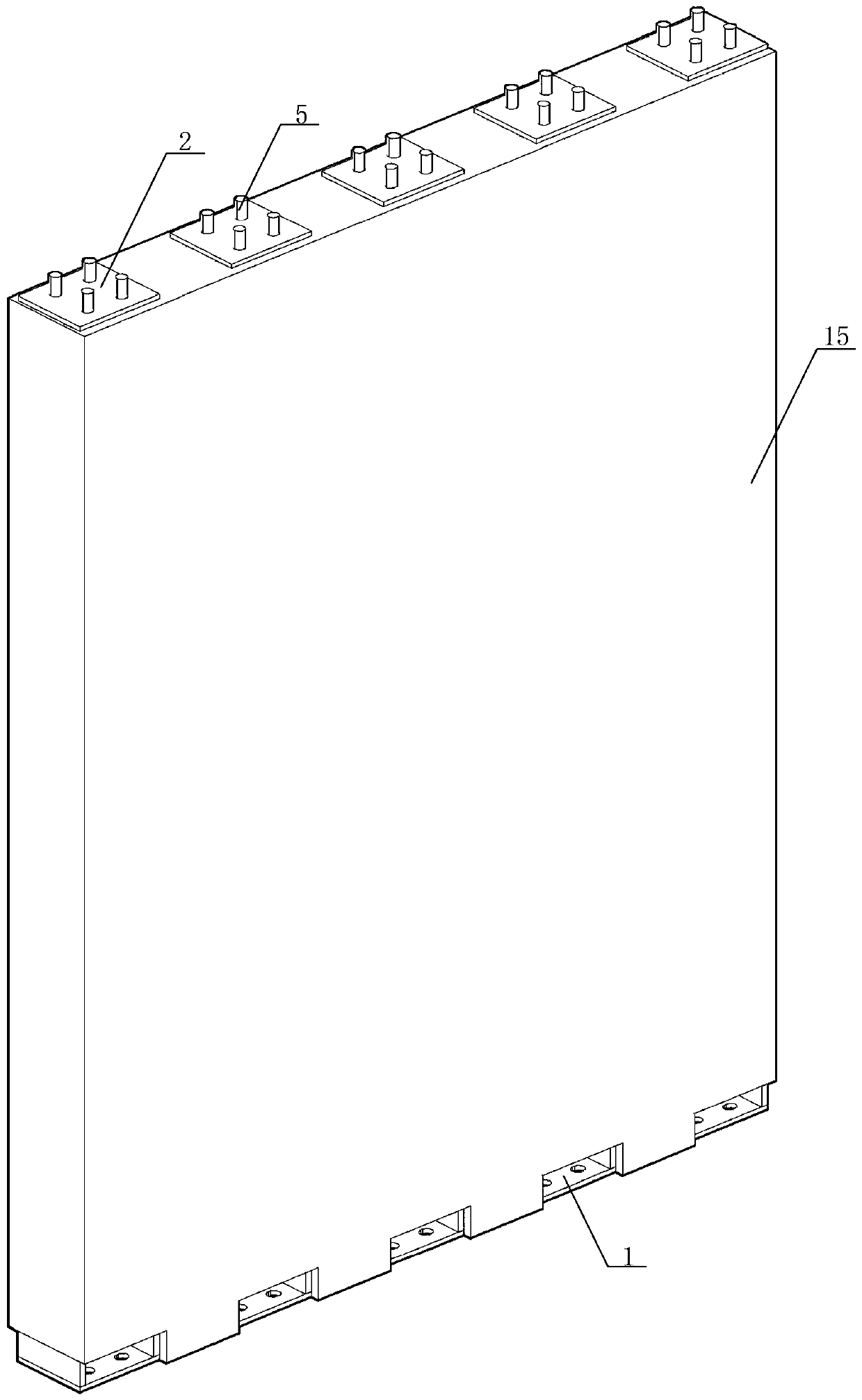

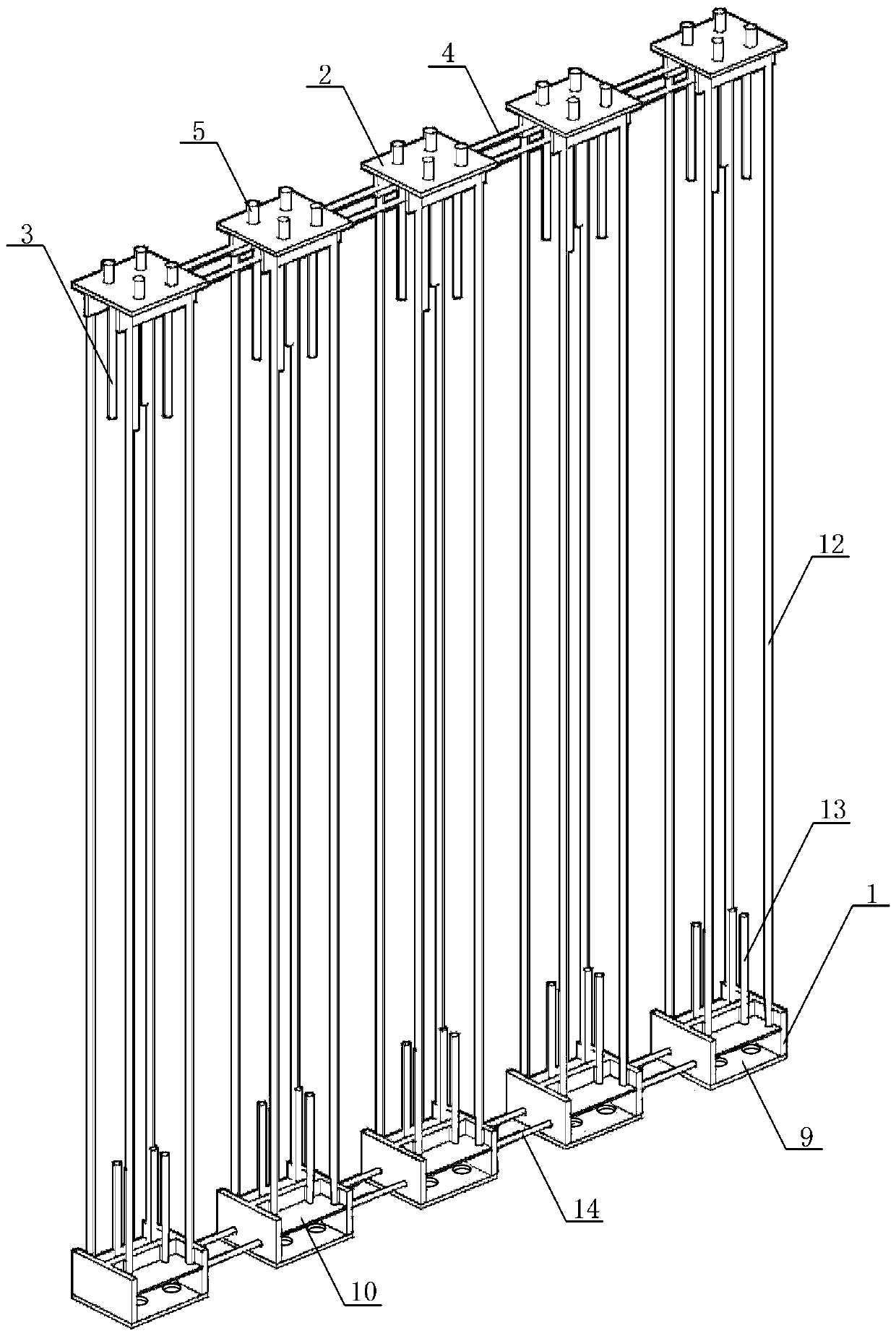

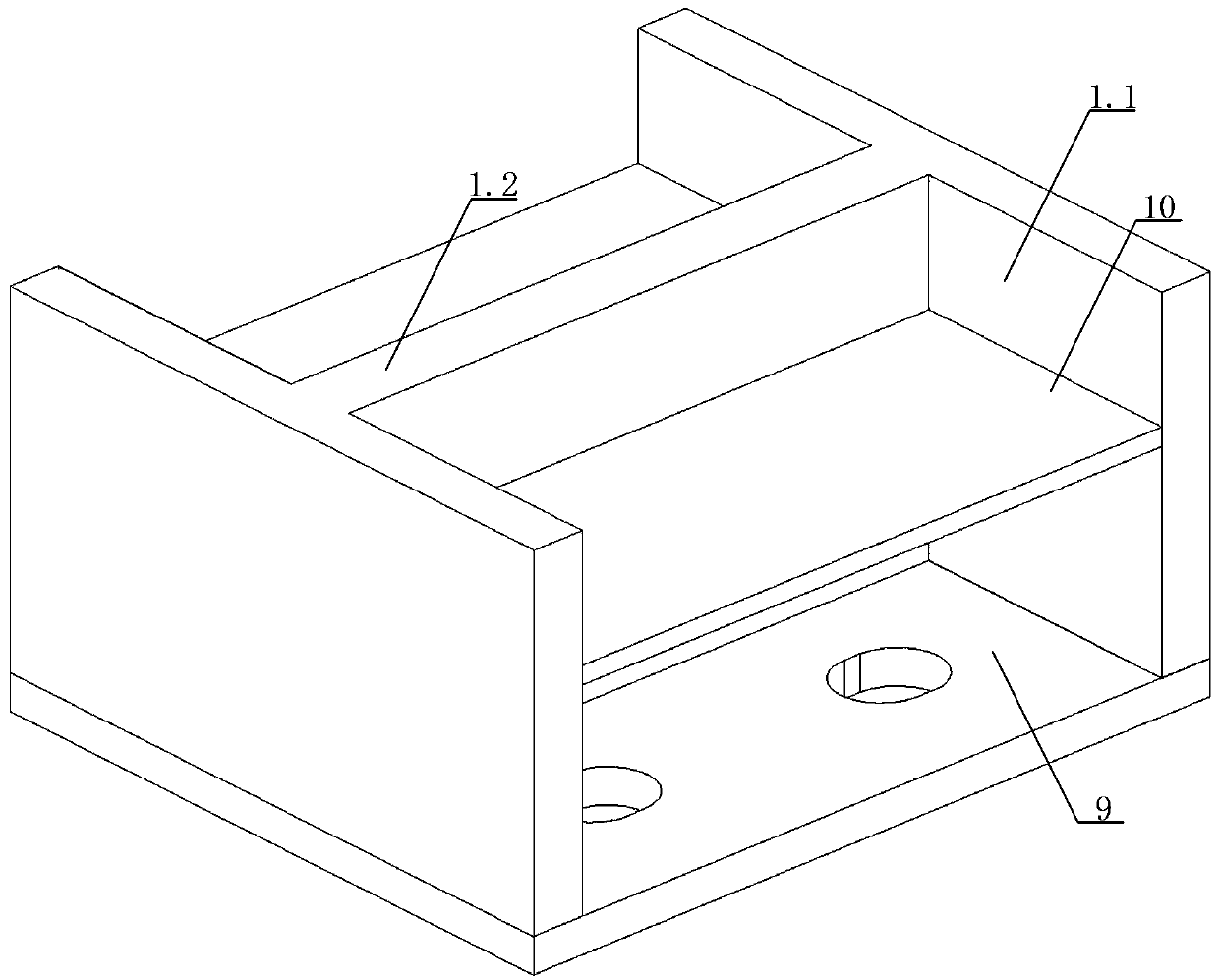

[0052] Examples see figure 1 As shown, this prefabricated shear wall panel includes a concrete main body 15 and a steel skeleton 16 poured in the concrete main body, see figure 2 As shown, the steel skeleton 16 includes a group of plug-in components arranged at the upper end of the wall board at even intervals along the length direction of the wall board, a receiving component corresponding to the plug-in component arranged at the lower end of the wall board, and a corresponding receiving component vertically connected to the wall board. and the vertical through-length steel bar group 12 between the plug-in components; the plug-in components are higher than the upper surface of the concrete body, and a group of upper horizontal connecting ribs 4 are horizontally connected between adjacent plug-in components, and each plug-in component A group of upper vertical reinforcing ribs 3 are vertically connected on the connecting components; the connecting components are connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com