Preparation method of monolayer lattice

A single-layer crystal, target substrate technology, applied in the field of lattice, can solve the problems of broken structure, high technical requirements for film production, film structure defects, etc., to achieve the effect of improving repeatability, high adjustability and reducing cracks

Active Publication Date: 2020-12-01

SOUTH CHINA NORMAL UNIVERSITY

View PDF10 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The disadvantages of the LB deposition method are: 1. When the nanospheres are very close to each other, since the adhesion force when the LB film is deposited on the substrate depends on the intermolecular force, there is a strong electrostatic repulsion between the particles, and there is also Due to the influence of Brownian motion, the lack of adhesive between particles cannot make it form a stable structure, especially when the film structure is transferred to the substrate, it is difficult to ensure that the structure will not be destroyed; 2. To obtain neat and orderly The LB film must contain amphoteric groups, which brings difficulties to the design of LB film-forming materials to a certain extent; 3. Toxic organic solvents such as chloroform need to be used in the film-making process, which is harmful to human health and the environment. Very harmful; 4. Membrane-making equipment is expensive, and membrane-making technology requires high requirements

The disadvantage of the convective deposition method is that the evaporation and drying process of water has an important impact on the order of the film structure, especially on the substrate with poor hydrophilicity, and this method is affected by multiple factors, such as substrate affinity. Water and roughness, nanosphere suspension concentration, ambient temperature and humidity, etc., and the production process takes a long time, and the repeatability of the experiment is poor, especially transferring the membrane structure to the required substrate is a big problem. Challenging, demanding and complex operation of the experimental setup

The disadvantage of the spin coating method is that the so-called "coffee ring" effect (causing the film to become a ring-shaped multilayer structure due to the accumulation of edge particles) will seriously affect the quality of the film structure, and the production Large-area, orderly, and single-layer two-dimensional structures are very difficult. In addition, the speed and acceleration of the spin coater are one of the important reasons for the defects in the film structure, although the electromagnetic effect can be used to deal with the alignment process. Properly regulated, but there are strict requirements on the nanospheres to be self-assembled and the final structure formed, and many substrates are not suitable for this method

[0007] 1. For the preparation of the concentration of the suspension (in deionized water, configure a certain mass fraction of the suspension of small balls, and then mix it in absolute ethanol): make the small balls spread smoothly on the water surface, and self-assemble into a compact The optimal concentration of the arranged hexagonal lattice is related to the size of the balls, ambient temperature, surfactant concentration, etc., and it is difficult to find a suitable dispersion concentration; if the concentration of the ball suspension is too high or the specific gravity of absolute ethanol is too high, small If the balls cannot be dispersed, it is easy to form a multi-layered and disordered structure on the liquid surface; on the contrary, if it is too low, it will cause the nanospheres to disperse too fast on the water surface, and even enter below the liquid surface, which will lead to poor repeatability of the experiment.

[0008] 2. In the process of dropping the suspension, it is necessary until the balls cover the entire interface: 1. Only a small part is transferred to the substrate, and the utilization rate of the balls is low; 2. It is easier to cause Damage; 3. Some small balls are easy to sink under the water surface, forming a multi-layer structure

[0009] 3. After the small balls are arranged, due to the influence of electrostatic repulsion and Brownian motion, the small balls lack a suitable adhesive, so they cannot form a stable structure and are prone to damage, especially during the transfer process.

[0010] 4. The transfer of the membrane structure generally adopts the vertical pulling method and the side wall transfer method. During the transfer process, it is easy to cause large fluctuations in the water surface, and the upper balls are easy to cover the lower balls, especially it is difficult to transfer to poor hydrophilicity. Severe damage to the structure on or after transfer

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

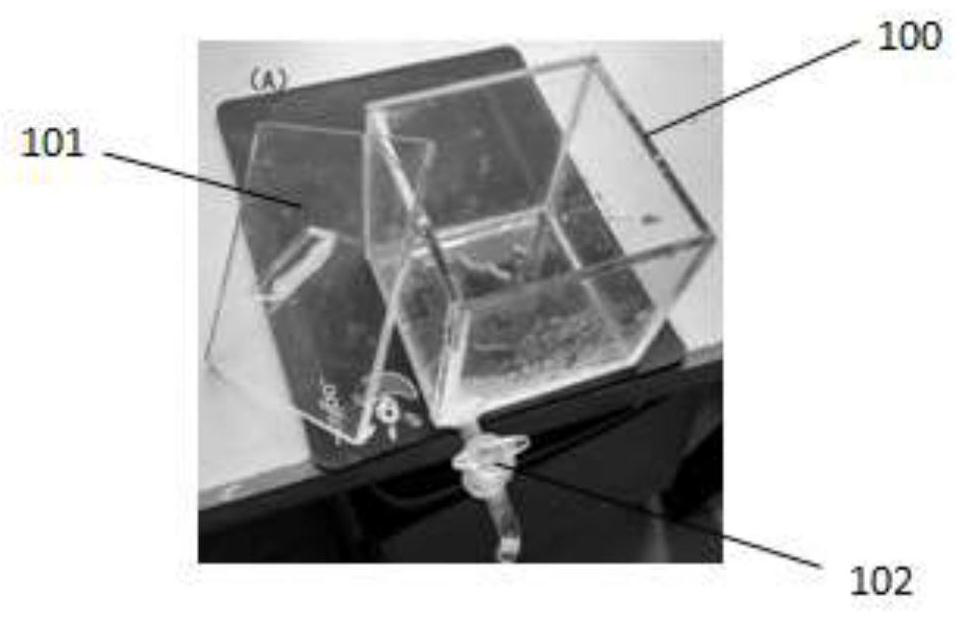

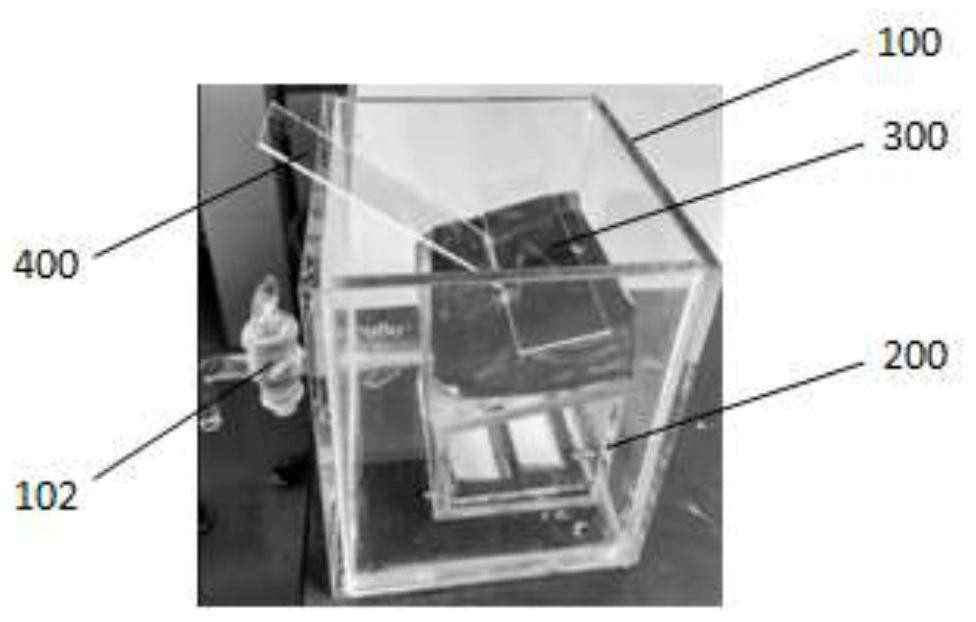

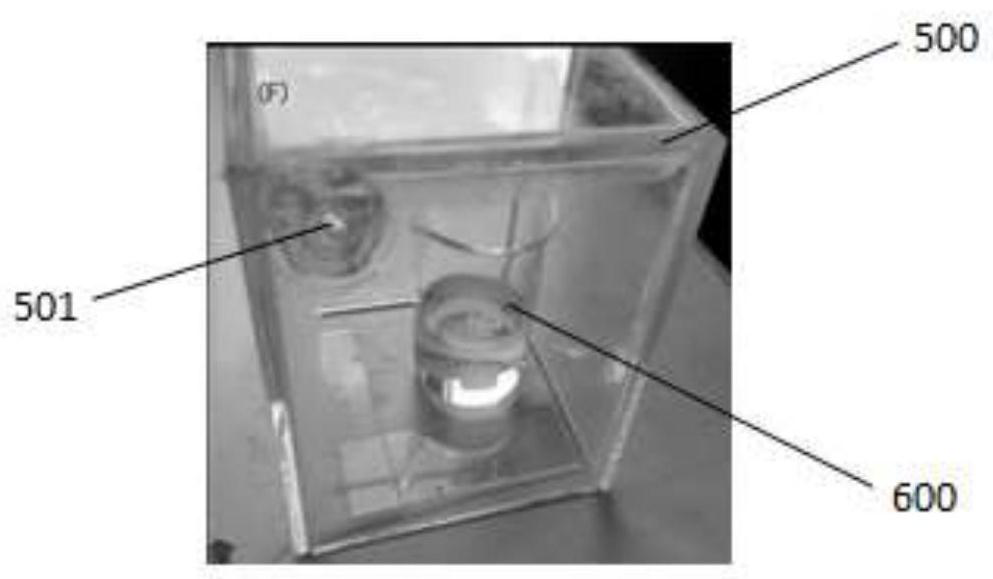

[0038] In this embodiment, a large-area, orderly, single-layer closely arranged hexagonal lattice is taken at the air-water interface as an example to illustrate the preparation method of the single-layer lattice of the present invention, which specifically includes the following steps:

[0039] 1. Prepare experimental materials and devices:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Login to View More

Abstract

The present invention relates to a single-layer crystal lattice preparation method, which comprises: placing a substrate and a target substrate in a container with a water discharging switch, whereinthe upper surface of the substrate is inclined, and the target substrate is placed on the substrate; obliquely placing a conduction slide so as to make the lower end of the conduction slide bear against the target substrate; adding deionized water, a binder solution and a surfactant solution into the container to form a boundary line between the conduction slide and the liquid surface; adding a small ball suspension liquid at the boundary line between the conduction slide and the liquid surface in a dropwise manner, wherein the small balls are spread on the liquid surface to form a film structure; taking out the conduction slide, adjusting the film structure to make the film structure be positioned above the target substrate, opening the water discharging switch after the liquid surface isstable, and making the liquid surface descend so as to make the film structure be positioned at the target substrate; and taking out the target substrate, placing into an environment filled with absolute ethanol, and drying to obtain the single-layer crystal lattice. According to the present invention, the preparation method has advantages of simple and convenient operation process, high repeatability, and less lattice defects.

Description

technical field [0001] The invention relates to the field of crystal lattices, in particular to a preparation method of a single-layer lattice. Background technique [0002] Nanostructures have a wide range of applications, such as 3D printing, fabrication of optical filters, waveguides, sensors, metal periodic structures for enhanced Raman scattering, etc. Traditional focused ion beam etching and electron beam etching directly fabricate nanostructures on the substrate, which is costly, low yield, and time-consuming. Since the nanosphere etching technology was proposed, nanostructures can be produced in a large area at a low cost in a short period of time. This method is based on a single-layer array of nanospheres arranged in an orderly manner as a template for the final structure. The advantages and disadvantages of the template are great. The degree determines the quality of the nanostructure. Therefore, it is very critical to fabricate a large-area single-layer templat...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C30B19/06C30B19/10C30B33/02

Inventor 胡立中许海霞陈溢杭

Owner SOUTH CHINA NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com