Aluminum alloy strip for integrated battery cover plate and preparing method of aluminum alloy strip

A technology for aluminum alloy strips and battery cover plates, which is applied in battery pack parts, circuits, electrical components, etc., can solve the problems of unspecified casting process and processing softening characteristics, and achieve excellent laser welding performance, stable blasting pressure, The effect of cost advantage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The composition of the aluminum alloy strip is calculated by mass fraction: Fe 1.3%, Mn 0.38%, Si 0.1%, Ti 0.008%, Cu 0.002%, Mg 0.006%, Zn 0.003%, and the balance is aluminum and unavoidable impurities.

[0037] A method for preparing the aluminum alloy strip for the integrated battery cover as described above, the specific steps are:

[0038] (1) Cast aluminum alloy flat ingots with specifications of 500mm*1350mm*5800mm by semi-continuous casting method, and the casting speed is 50mm / min;

[0039] (2) After the slab is milled with 12mm / large surface, it enters the vertical pusher furnace for homogenization heat treatment, the heating temperature is 580°C, the holding time is 10 hours, and it is hot-rolled to a hot-rolled coil with a thickness of 8mm, and the final rolling temperature is 320°C;

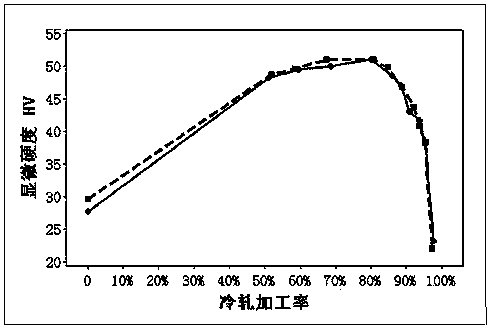

[0040] (3) The hot-rolled coils are cold-rolled in the cold-rolling mill to a finished product thickness of 1.5mm, and the total processing rate of cold-rolling is 81.25%;

...

Embodiment 2

[0045] The composition of the aluminum alloy strip is calculated by mass fraction: Fe 1.3%, Mn 0.3%, Si 0.12%, Ti 0.008%, Cu 0.003%, Mg 0.002%, Zn 0.004%, and the balance is aluminum and unavoidable impurities.

[0046] A method for preparing the aluminum alloy strip for the integrated battery cover as described above, the specific steps are:

[0047] (1) Cast aluminum alloy flat ingots with specifications of 560mm*1300mm*6000mm by semi-continuous casting method, and the casting speed is 55mm / min;

[0048] (2) The slab enters the vertical pusher furnace for homogenization heat treatment through milling of 15mm / large surface, the heating temperature is 620°C, the holding time is 8 hours, and it is hot-rolled to a hot-rolled coil with a thickness of 4.0mm, and the final rolling temperature is 280°C;

[0049] (3) The hot-rolled coils are cold-rolled in the cold-rolling mill to a finished product thickness of 1.0mm, and the total processing rate of cold-rolling is 75%;

[0050] (...

Embodiment 3

[0054] The composition of the aluminum alloy strip is calculated by mass fraction: Fe 1.32%, Mn 0.48%, Si 0.12%, Ti 0.007%, Cu 0.003%, Mg 0.002%, Zn 0.003%, and the balance is aluminum and unavoidable impurities.

[0055] A method for preparing the aluminum alloy strip for the integrated battery cover as described above, the specific steps are:

[0056] (1) Cast aluminum alloy flat ingots with specifications of 560mm*1300mm*5800mm by semi-continuous casting method, and the casting speed is 60mm / min;

[0057] (2) Flat ingot The flat ingot is milled with 18mm / large surface and enters the vertical pusher furnace for homogenization heat treatment. The heating temperature is 610°C, the holding time is 15 hours, and it is hot-rolled to a hot-rolled coil with a thickness of 6.0mm. The final rolling temperature is 320 ℃;

[0058] (3) The hot-rolled coils are cold-rolled in the cold-rolling mill to a finished product thickness of 1.2mm, and the total processing rate of cold-rolling is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com