Multifunctional accelerant for amino baking paint, and preparation method of multifunctional accelerant

An amino baking paint, multi-functional technology, applied in coatings, anti-corrosion coatings, polyester coatings and other directions, can solve the problems of cumbersome coating production process, decreased coating stability, high coating cost, improve wiping performance, improve solvent resistance , the effect of improving the wettability of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

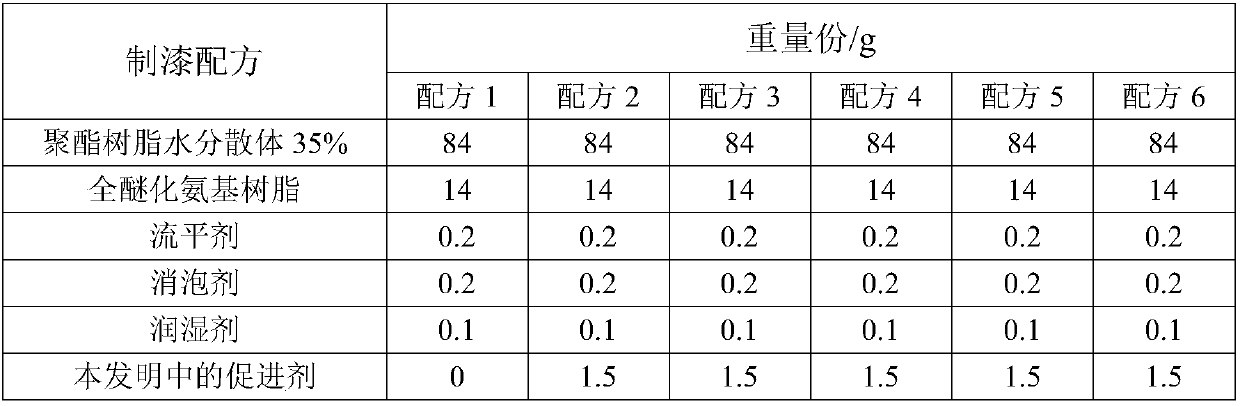

Examples

Embodiment 1

[0034] The multifunctional accelerator for amino baking varnish provided in this example is mainly made of the following raw materials in proportion by mass: 150% epoxy resin, 25.9% phosphoric acid compound, 57.6% glycidyl aliphatic compound, and the amount of organic solvent to dissolve epoxy Resin is suitable, here is 98.

[0035] Wherein the epoxy resin has an epoxy value of 0.2-0.6 mol / 100g epoxy resin, specifically E-20 epoxy resin.

[0036] The phosphoric acid compound is phosphoric acid with a mass percent content of 85%.

[0037] The glycidyl aliphatic compound is an aliphatic compound with an epoxy functional group capable of reacting with acid and grafting, specifically glycidyl tertiary carbonic acid ester.

[0038] Organic solvents are anti-white water.

[0039] The preparation method of the multifunctional accelerator for amino baking varnish comprises the following steps:

[0040] (1) Take 150 parts of E-20 epoxy resin and 98 parts of anti-white water into the...

Embodiment 2

[0046] The multifunctional accelerator for amino baking varnish provided in this embodiment is mainly made of the following raw materials in proportion by mass: epoxy resin 150, phosphoric acid compound 50.7, glycidyl aliphatic compound 26.4, organic solvent in an amount capable of dissolving epoxy Resin is suitable, here is 110.

[0047] Wherein the epoxy resin has an epoxy value of 0.2-0.6 mol / 100g epoxy resin, specifically E-44 epoxy resin.

[0048] The phosphoric acid compound is phosphoric acid with a mass percent content of 85%.

[0049] The glycidyl aliphatic compound is an aliphatic compound with an epoxy functional group capable of reacting with acid and grafting, specifically glycidyl tertiary carbonic acid ester.

[0050] Organic solvents are anti-white water.

[0051] The preparation method of the multifunctional accelerator for amino baking varnish comprises the following steps:

[0052] (1) Take 150 parts of E-44 epoxy resin and 110 parts of anti-white water i...

Embodiment 3

[0058] The multifunctional accelerator for amino baking varnish provided in this embodiment is mainly made of the following raw materials in proportion by mass: epoxy resin 150, phosphoric acid compound 63.4, glycidyl aliphatic compound 33, organic solvent in an amount capable of dissolving epoxy Resin is suitable, here is 118.

[0059] Wherein the epoxy resin has an epoxy value of 0.2-0.6 mol / 100g epoxy resin, specifically E-55 epoxy resin.

[0060] The phosphoric acid compound is phosphoric acid with a mass percent content of 85%.

[0061] The glycidyl aliphatic compound is an aliphatic compound with an epoxy functional group capable of reacting with acid and grafting, specifically glycidyl tertiary carbonic acid ester.

[0062] Organic solvents are anti-white water.

[0063] The preparation method of the multifunctional accelerator for amino baking varnish comprises the following steps:

[0064] (1) Take 150 parts of E-55 epoxy resin and 118 parts of anti-white water int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com