Composite antibacterial coating for children's bicycles, composite antibacterial agent and preparation method of composite antibacterial agent

A compound antibacterial agent and compound antibacterial technology, applied in the field of coatings, to achieve the effect of good stability, stable performance, and excellent antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

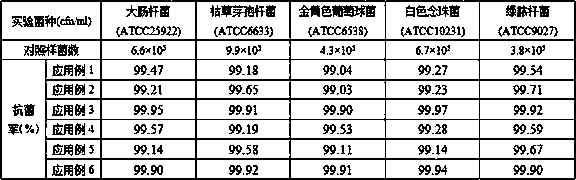

Examples

Embodiment 1

[0029] (1) Weigh 100 parts of microcrystalline kaolinite powder and add 350 parts of deionized water to prepare mixed solution A; mix (1+1) hydrochloric acid, (1+1) sulfuric acid and (1+1) phosphoric acid according to 1 : Prepare a mixed acid solution with a pH of 5-6 at a ratio of 1:2; add the mixed solution A dropwise to the mixed acid solution at a rate of 5mL / min, heat to 50°C, and stir at a constant speed for 4 hours to obtain a mixed solution B;

[0030] (2) Add 100 parts of nano-titanium dioxide to the above mixed solution B, and after stirring at a constant speed for 5 hours at 60°C, add 0.007 parts of bromochlorohydantoin and 100 parts of dodecyl-dimethyl-benzyl chloride ammonium chloride, 50 parts of fluorosilane coupling agent, 30 parts of 2,6-di-tert-butyl-4-methylphenol and 10 parts of thiodiacrylate, heated to 80°C, stirred at a constant speed for 5 hours, and mixed Liquid C;

[0031] (3) Suction filter the above mixture C, discard the filtrate, wash the filter ...

Embodiment 2

[0033] (1) Weigh 200 parts of microcrystalline kaolinite powder and add 800 parts of deionized water to prepare a mixed solution A; mix (1+1) hydrochloric acid, (1+1) sulfuric acid and (1+1) phosphoric acid according to 1 : Prepare a mixed acid solution with a pH of 5-6 at a ratio of 1:3; add the mixed solution A dropwise to the mixed acid solution at a rate of 5 mL / min, heat to 70° C., and stir at a constant speed for 6 hours to obtain a mixed solution B;

[0034] (2) Add 200 parts of nano-zinc-loaded hydroxyapatite to the above mixture B, and after stirring at a constant speed for 8 hours at a temperature of 70°C, add 0.014 parts of bromochlorohydantoin and 150 parts of dodecyl-di Methyl-benzyl ammonium chloride, 80 parts of fluorosilane coupling agent, 50 parts of 2,6-di-tert-butyl-4-methylphenol and 20 parts of thiodiacrylate, heated to 90°C, Stir at a constant speed for 8 hours to obtain a mixed solution C;

[0035] (3) Suction filter the above mixture C, discard the fil...

Embodiment 3

[0037] (1) Weigh 150 parts of microcrystalline kaolinite powder and add 500 parts of deionized water to prepare a mixed solution A; mix (1+1) hydrochloric acid, (1+1) sulfuric acid and (1+1) phosphoric acid according to 1 : Prepare a mixed acid solution with a pH of 5-6 at a ratio of 1:2; add the mixed solution A dropwise to the mixed acid solution at a rate of 5 mL / min, heat to 60° C., and stir at a constant speed for 5 hours to obtain a mixed solution B;

[0038] (2) Add 150 parts of inorganic antibacterial agent to the above mixed solution B, and after stirring at a constant speed for 7 hours at 65°C, add 0.010 parts of bromochlorohydantoin and 130 parts of dodecyl-dimethyl-benzyl ammonium chloride, 60 parts of fluorosilane coupling agent, 40 parts of 2,6-di-tert-butyl-4-methylphenol and 15 parts of thiodiacrylate, the temperature was raised to 85 ° C, and stirred at a constant speed for 6 hours, Obtain mixed solution C;

[0039] (3) Suction filter the above mixture C, dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com