Method for catalyzing methyl acetate transesterification with polyacid ionic liquid

A methyl acetate, ionic liquid technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc., can solve the problems of mass transfer, side reactions, equipment corrosion and other problems, to achieve the effect of broad industrial application prospect, simple synthesis method and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

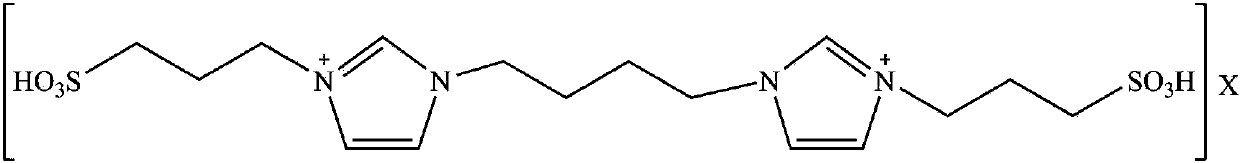

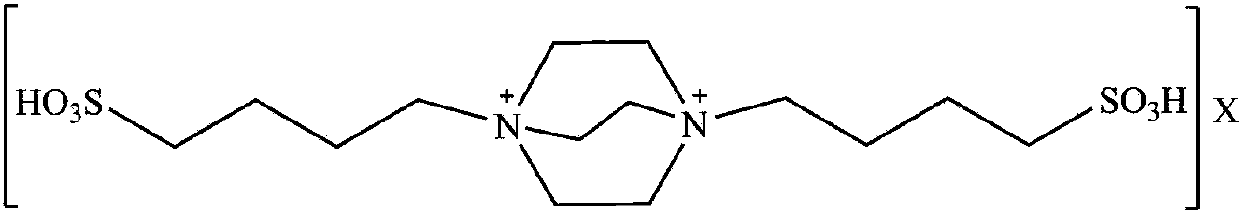

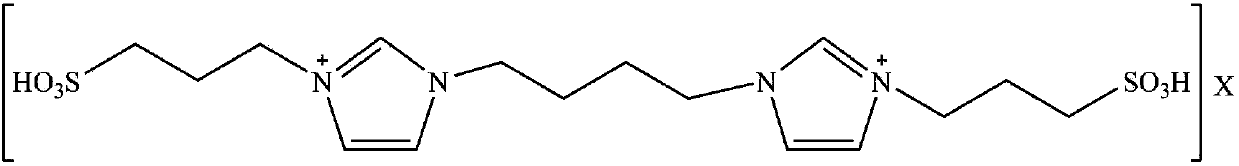

[0026] In the reactor, add 7.4g (0.1mol) of methyl acetate, 6.9g (0.15mol) of ethanol and 0.286g of bisimidazole butyl sultone phosphomolybdate ionic liquid (accounting for 2wt% of the total mass of raw materials) in sequence , Heating with stirring to a reaction temperature of 60°C, constant temperature reaction for 4h, the conversion rate of methyl acetate is 55%.

Embodiment 2

[0028] In the reactor, add 7.4g (0.1mol) of methyl acetate, 9.015g (0.15mol) of n-propanol and 0.524g of bisimidazole butyl sultone tungstate ionic liquid (accounting for 3wt of the total mass of raw materials) in the reactor. %), heating with stirring to a reaction temperature of 50°C, constant temperature reaction for 7 hours, the conversion rate of methyl acetate is 37%.

Embodiment 3

[0030] In the reactor, add 7.4g (0.1mol) of methyl acetate, 22.24g (0.3mol) of n-butanol and 2.07g of bisimidazole butyl sultone phosphomolybdate ionic liquid (accounting for 7wt of the total mass of the raw materials). %), heating with stirring to a reaction temperature of 70°C, constant temperature reaction for 8 hours, the conversion rate of methyl acetate is 48%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com