Driver for processing and pushing glass bead

A transmission device and glass bead technology, which is applied in cleaning devices, conveyor objects, transportation and packaging, etc., can solve the problems of inconvenient disassembly and maintenance, poor lubrication effect, loose rolling, etc., to prevent device jamming, easy disassembly, The effect of convenient lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

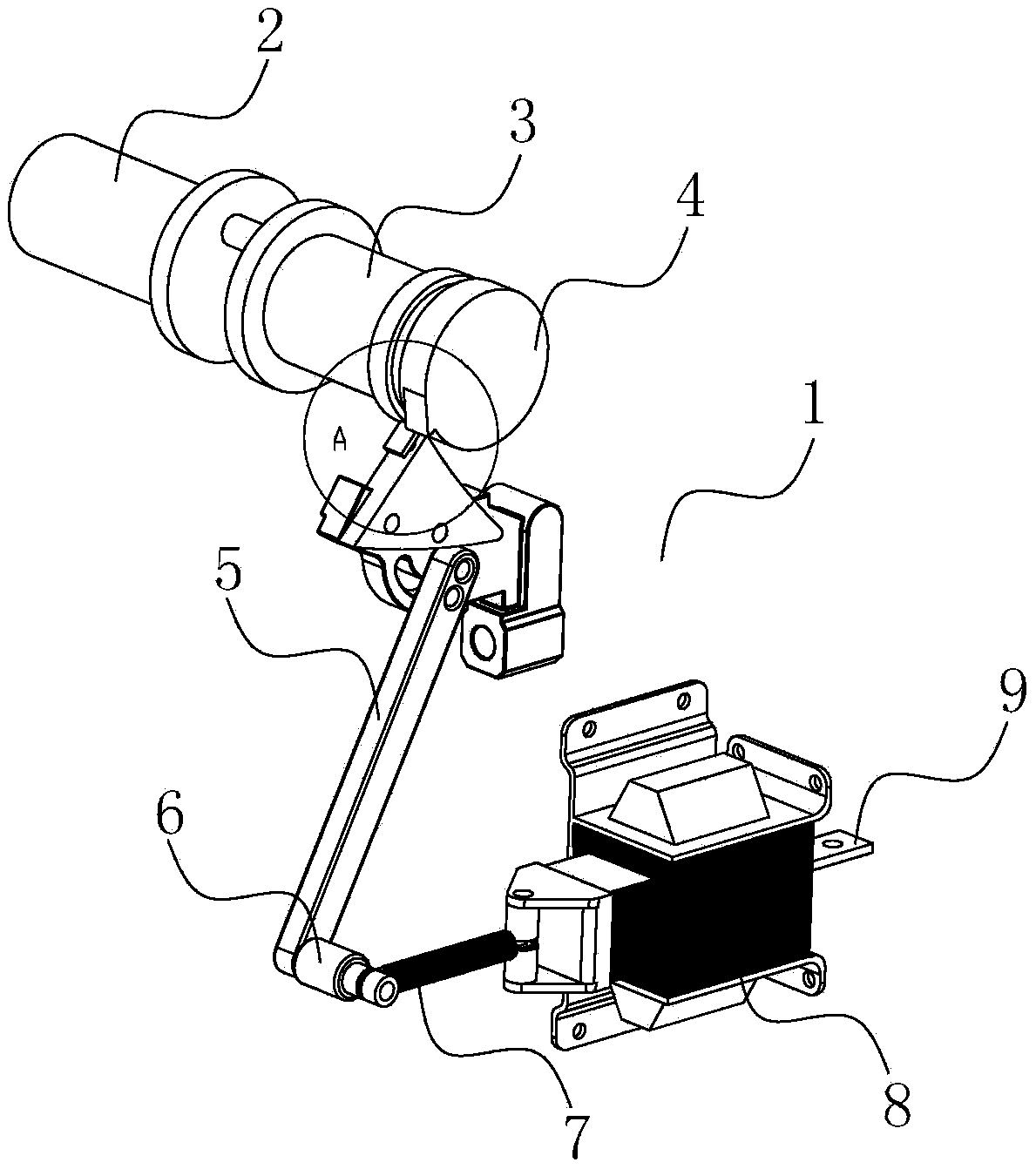

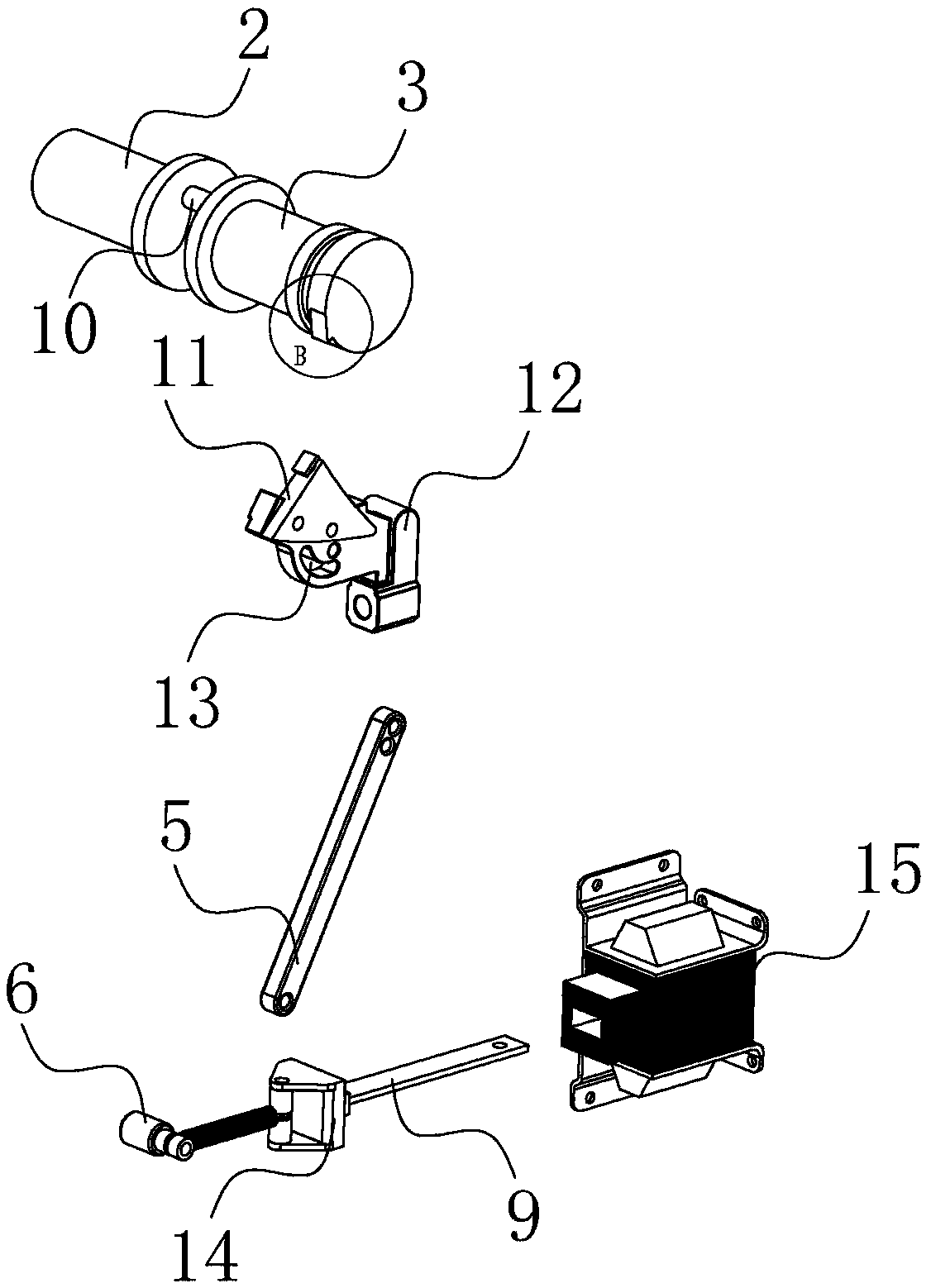

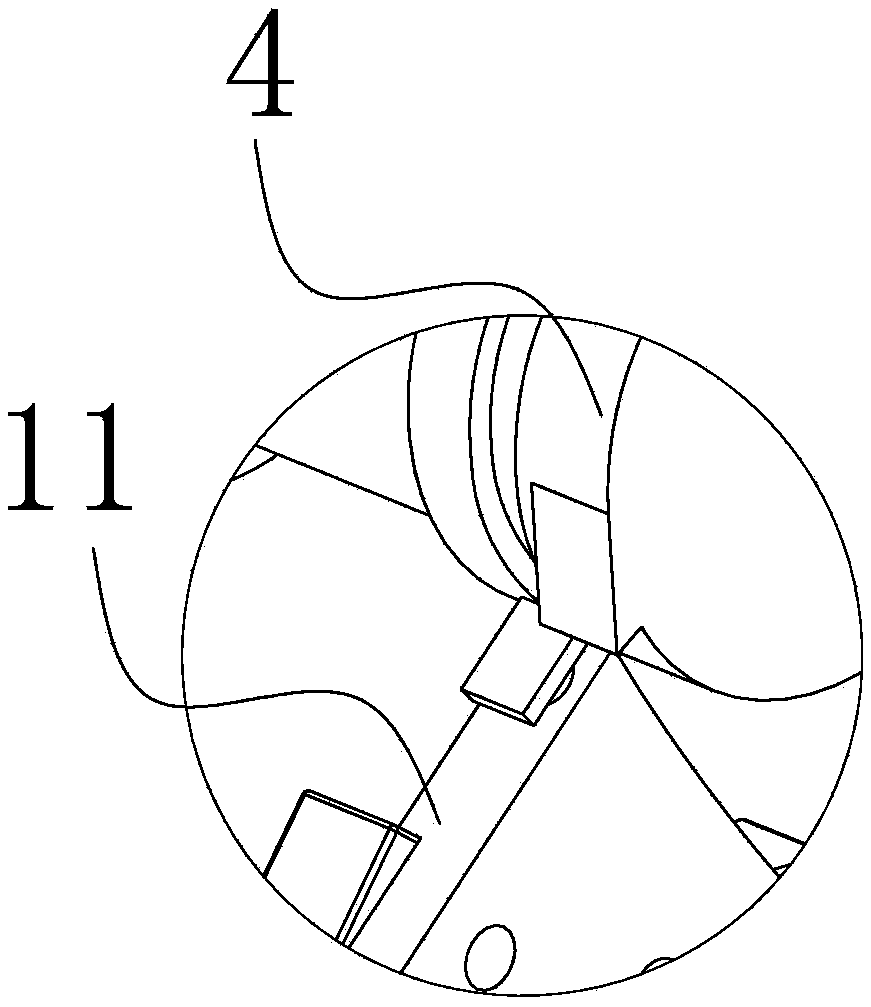

[0021] like Figure 1 to Figure 5 As shown, the transmission device 1 used for glass bead processing and pushing includes a motor 2 arranged horizontally, one end of the motor 2 is provided with a rotating rod 10, and one end of the rotating rod 10 is provided with a drum 3, and the rotating drum 3 One end is provided with a turntable 4, a transmission block 11 is arranged below the turntable 4, a support frame 12 is installed on the bottom of the transmission block 11, a movable groove 13 is arranged at the bottom of the support frame 12, and a connecting frame 13 is installed inside the movable groove 13. Rod 5, one end of this connecting rod 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com