Ejection seat stabilization parachute

A technology for ejecting seats and stabilizing umbrellas, which is applied in the field of parachutes, can solve the problems of low aerodynamic efficiency, heavy weight, processing dimensions, and assembly dimensional accuracy requirements of seat stabilizing umbrellas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

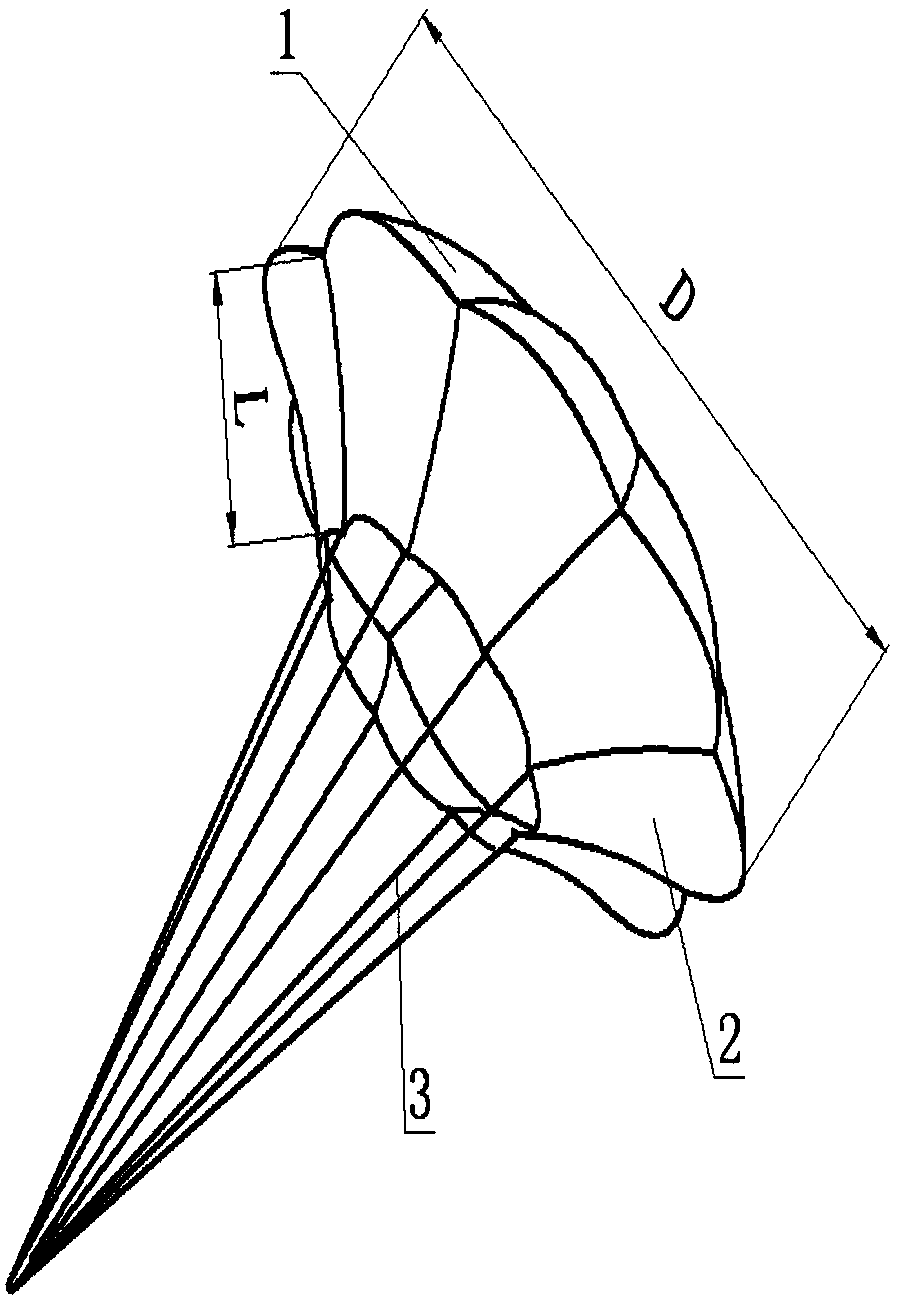

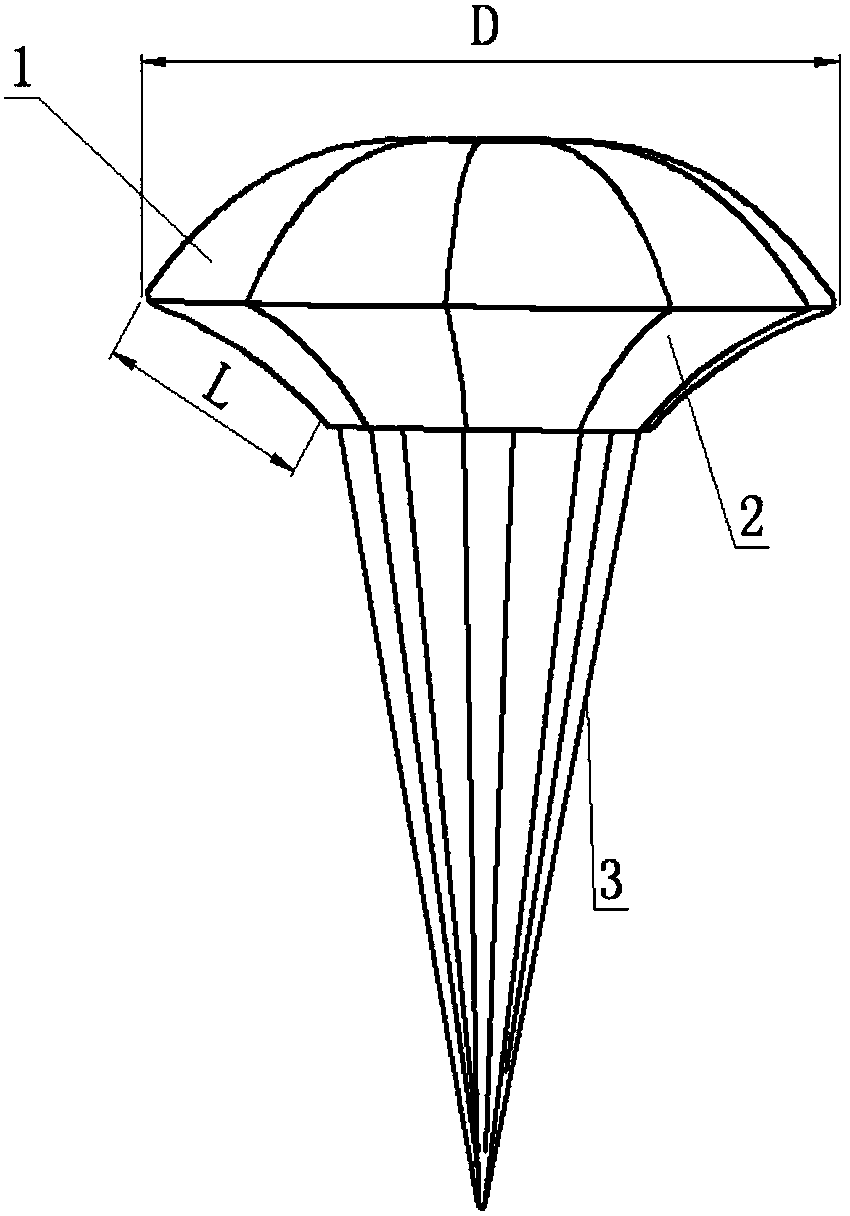

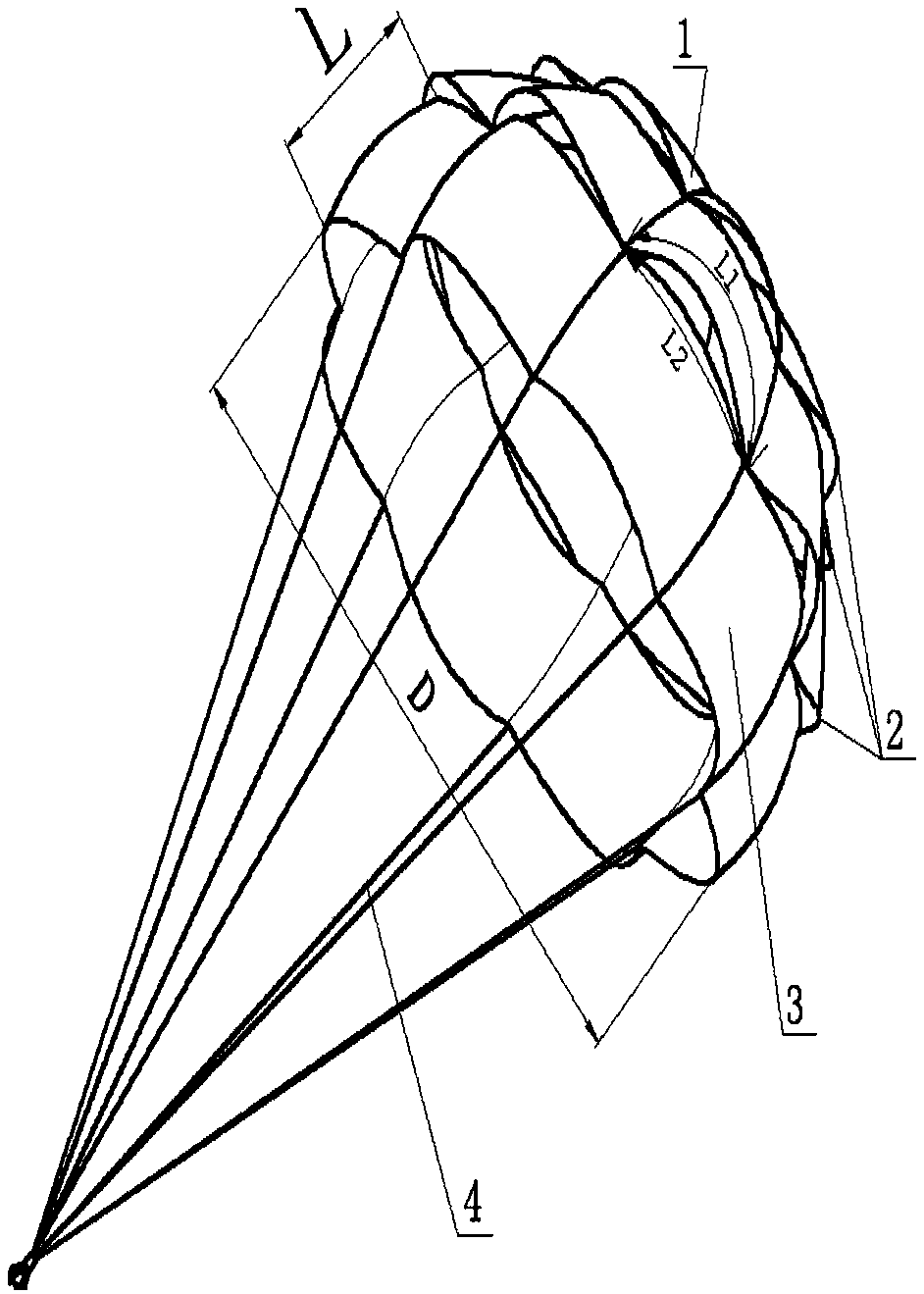

[0018] like image 3 and Figure 4 As shown, an ejection seat stabilized umbrella includes a canopy and an umbrella rope 4, and the canopy includes a first-level top panel 1, a second-level top panel 1, and a skirt panel 3 connected in sequence from top to bottom, and the skirt panel 3 is outward Curved, the first-level top panel 1 and the second-level top panel 1 are stitched at intervals to form a row of evenly distributed crescent holes 2, and the second-level top panel 1 and skirt panel 3 are stitched at intervals to form another row of evenly distributed crescent holes 2 The openings of the upper row of crescent holes 2 are located above and outside the top panel 1, the openings of the lower row of crescent holes 2 are located above and outside the skirt panel 3, and the crescent holes 2 in the same row are of the same size.

[0019] In this embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com