Aluminum plate washing device

A cleaning device and aluminum plate technology, applied to the surface coating liquid device, smoke and dust removal, cleaning methods and utensils, etc., can solve the problems of long wasted time, inability to realize online cleaning operations, low processing efficiency, etc., and achieve structural Simple, efficient, and easy-to-manufacture effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with the accompanying drawings.

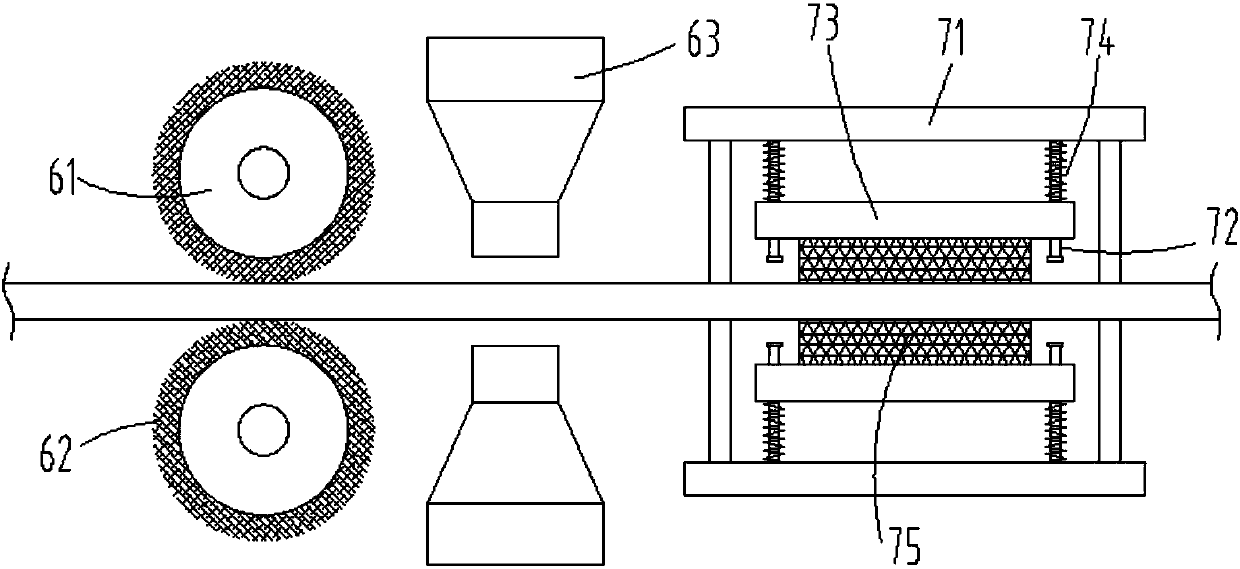

[0009] Such as figure 1 As shown, the present invention discloses an aluminum plate cleaning device, which includes a roller 61, a brush 62, an exhaust pipe 63, an exhaust fan, a mounting frame 71, a guide rod 72, a pressure plate 73, a spring 74 and a sponge 75, and the two rollers 61 are divided up and down. Layers are arranged, and a transmission gap is formed between the two rollers 61, the two brushes 62 are sleeved on the two rollers 61, the two exhaust pipes 63 correspond to the right sides of the two rollers 61, the exhaust end of the exhaust fan and the exhaust pipe 63 connected. Mounting frame 71 is positioned at the right side of exhaust duct 63, and four guide rods 72 are fixedly connected in pairs on the upper and lower both sides of mounting frame 71 respectively, and a spring 74 is sleeved on every guiding rod 72, two The pressing plate 73 is correspon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com