A kind of preparation method and application of ruthenium-cerium-zirconium solid solution catalyst

A cerium-zirconium solid solution and catalyst technology, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., to achieve the effects of high temperature resistance, good thermal stability and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A preparation method containing ruthenium cerium zirconium solid solution catalyst, the specific preparation method is as follows:

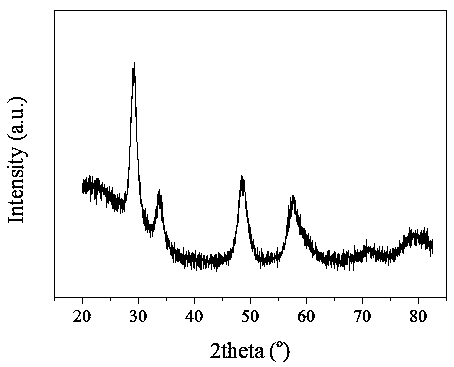

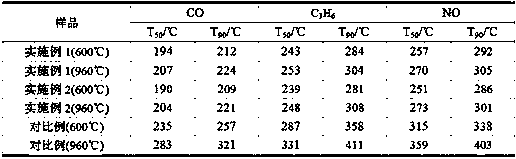

[0018] Dissolve 4.5 grams of ceric ammonium nitrate, 3.5 grams of zirconium oxychloride and 0.6 grams of lanthanum nitrate in 90 grams of deionized water, and slowly add 10% ammonia water dropwise while stirring, so that the pH of the solution is 1.5, place it in a water bath at 50°C for 24 hours, then add 3 grams of urea and 1 gram of 5% ruthenium chloride solution, and mix well. The obtained mixed solution was poured into a reaction kettle lined with polytetrafluoroethylene, and kept at 180° C. for 20 hours. The obtained precipitate was centrifuged and washed three times with deionized water. The washed precipitate was dried at 120° C. for 12 hours and calcined at 600° C. for 4 hours to obtain a solid solution catalyst containing ruthenium, cerium and zirconium. The above catalyst was calcined at 960° C. for 20 hours for rapid aging to ...

Embodiment 2

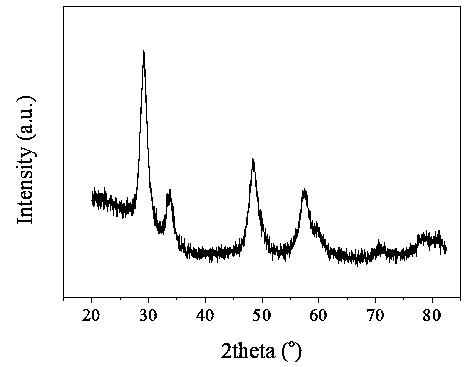

[0020] 43 grams of ceric ammonium nitrate, 36 grams of zirconium oxychloride and 7 grams of lanthanum nitrate were dissolved in 880 grams of deionized water, and slowly added dropwise 10% ammonia water while stirring, so that the pH of the solution was 1.5, place it in a water bath at 60°C for 12 hours, then add 22 grams of urea and 15 grams of 5% ruthenium chloride solution, and mix well. The obtained mixed solution was poured into a reaction kettle lined with polytetrafluoroethylene, and kept at 150° C. for 36 hours. The obtained precipitate was centrifuged and washed three times with deionized water. The washed precipitate was dried at 120° C. for 12 hours and calcined at 600° C. for 4 hours to obtain a ruthenium-cerium-zirconium solid solution catalyst. The above catalyst was calcined at 960° C. for 20 hours for rapid aging to obtain an aged catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com