Shock-absorbing and anti-galling interphase spacers for transmission line conductors

A technology of interphase spacer and sub-conductor spacer, which is applied in the direction of the device for maintaining the distance between parallel conductors and the mechanical vibration attenuation device, etc., which can solve the problems of steplessly adjustable interphase spacer bracket or complex structure of connecting fittings, and achieve the weakening effect Force, avoid stress concentration, reduce wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

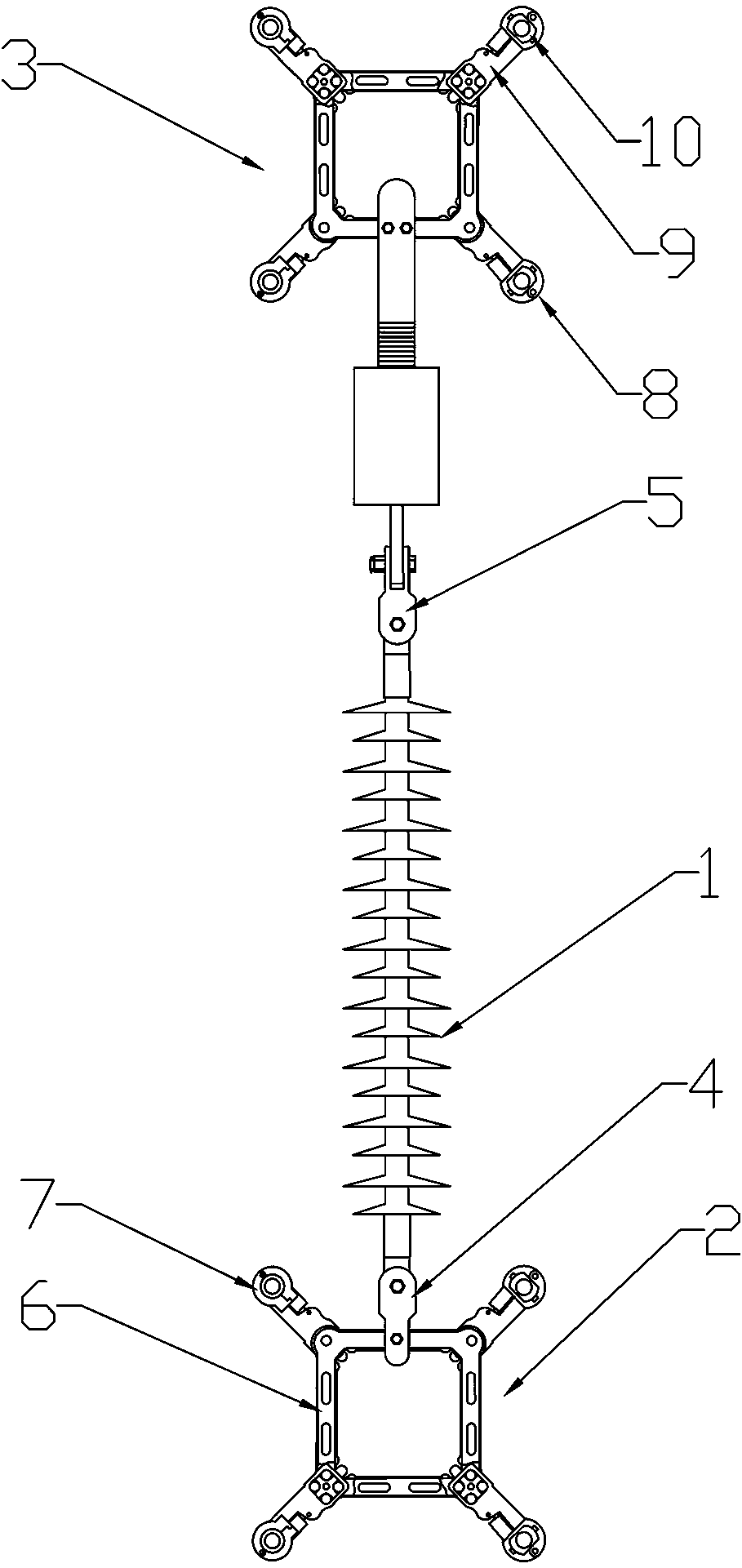

[0037] Such as figure 1 As shown, the shock-absorbing and anti-galling spacer between the wires of the transmission line includes a composite insulator 1, a sub-conductor spacer I2 and a sub-conductor spacer II3. The two ends of the composite insulator 1 are slot-shaped hole fittings, and the sub-conductor spacer I2 is hinged to the slot-shaped hole fitting at one end of the composite insulator 1 through a ZBD-type hanging plate 4, and the sub-conductor spacer II3 is hinged to the slot-shaped hole fitting at the other end of the composite insulator 1 through a right-angle hanging plate 5. An adjustable connection mechanism is connected between the right-angle hanging plate 5 and the sub-conductor spacer II3.

[0038] The sub-conductor spacer includes a spacer frame body 6, a rotary damping clamp 7 arranged on one side of the spacer frame body 6, and a fixed damper clamp arranged on the other side of the spacer frame body 6 8. Both the rotary damping clamp 7 and the fixed damp...

Embodiment 2

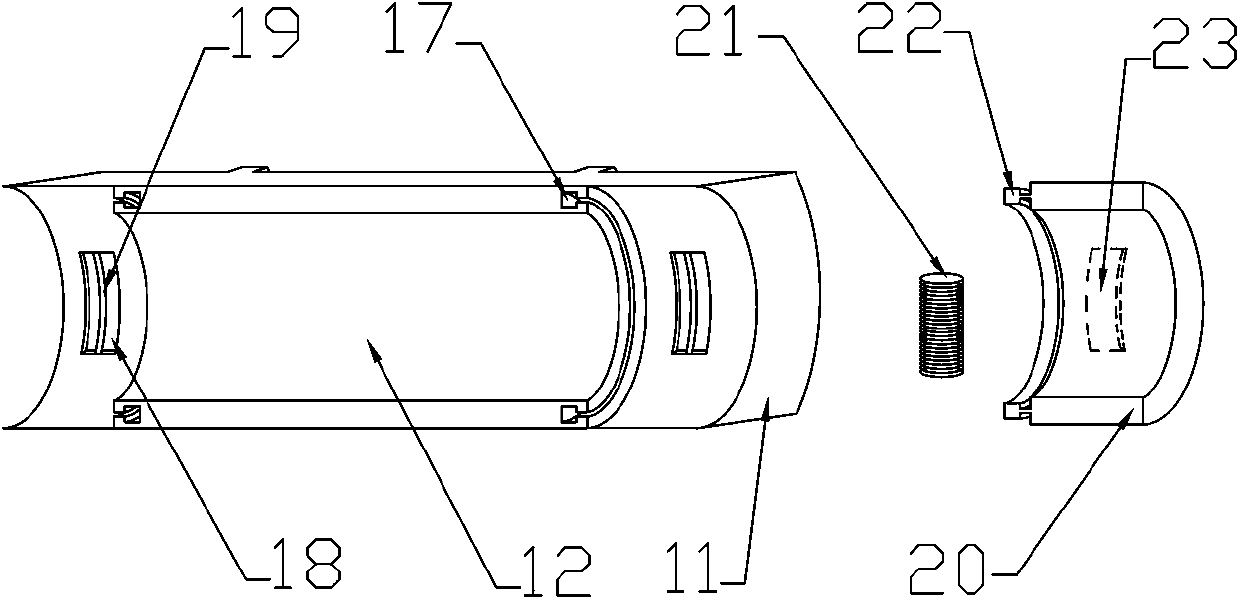

[0044] This embodiment is basically the same as the first embodiment, except that: the arc length of the T-shaped protrusion 22 is smaller than the arc length of the T-shaped sliding groove 17 .

Embodiment 3

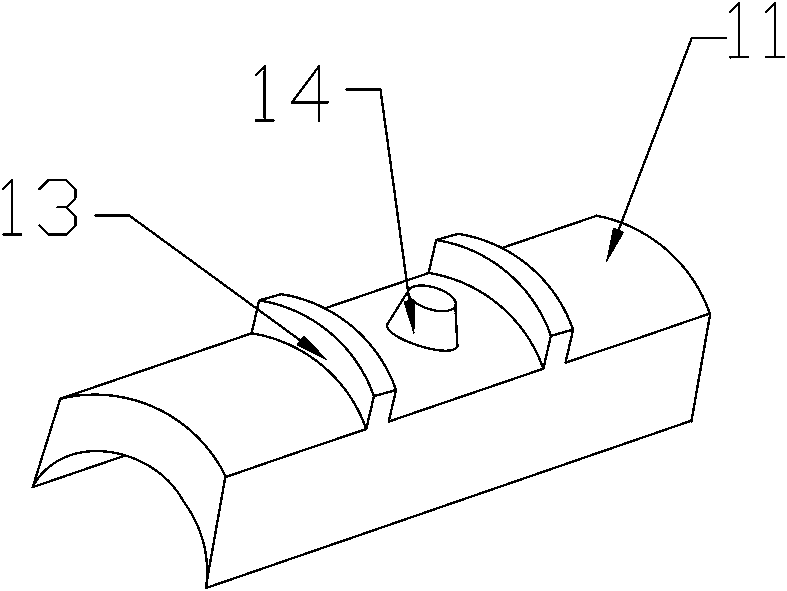

[0046] Such as Figure 4 , 7 As shown in -8, this embodiment is basically the same as the second embodiment, the difference is that: the frustum-shaped protrusion 14 is provided with a cylindrical fixing groove 37, and the inner wall of the fixing groove 37 is provided with a boss 38, the The upper surface of the boss 38 is arc-shaped, and the lower surface is vertical to the inner wall of the fixing groove 37. The T-shaped pin 39 is fixed in the said circular truncated through hole 16, and the pin shank diameter of the T-shaped pin 39 is larger than the said through hole. The pin shaft of the T-shaped pin 39 is placed in the fixed groove 37 through the frustum-shaped through hole 16, and the lower end of the pin shaft is a conical structure, and the pin shaft is provided with the boss 38. matching grooves.

[0047] During installation, the T-shaped pin 39 is fixed on the frustum-shaped through hole 16, and then the damping sleeve 10 is installed in the clamp body and the cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com