Wire connection device and using method thereof

A splicing device and wire joint technology, which is applied in the direction of conductive connection, connection, and electrical component connection, can solve the problems of unfavorable fast operation, easy wear of wires, and slow connection speed, so as to improve connection efficiency, avoid torsion fracture, and weaken the effect force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

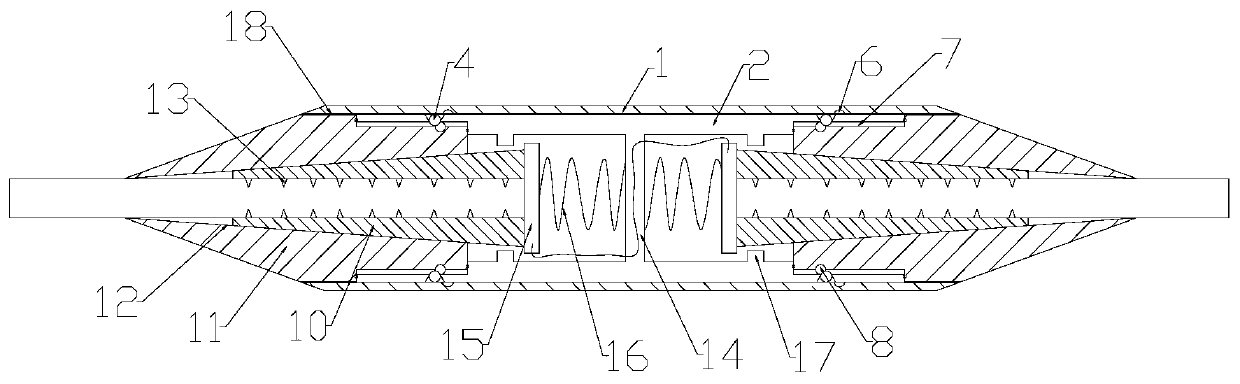

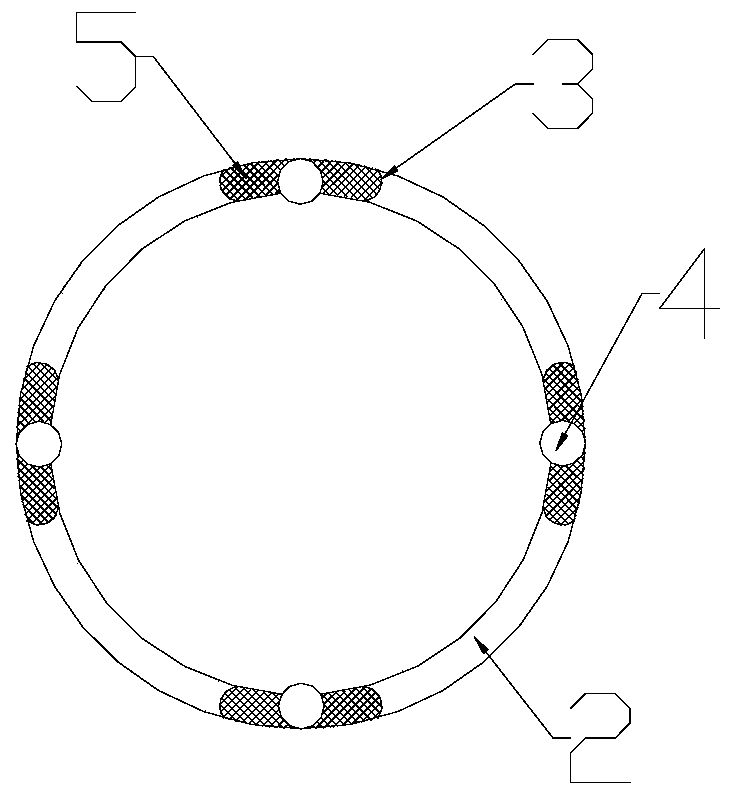

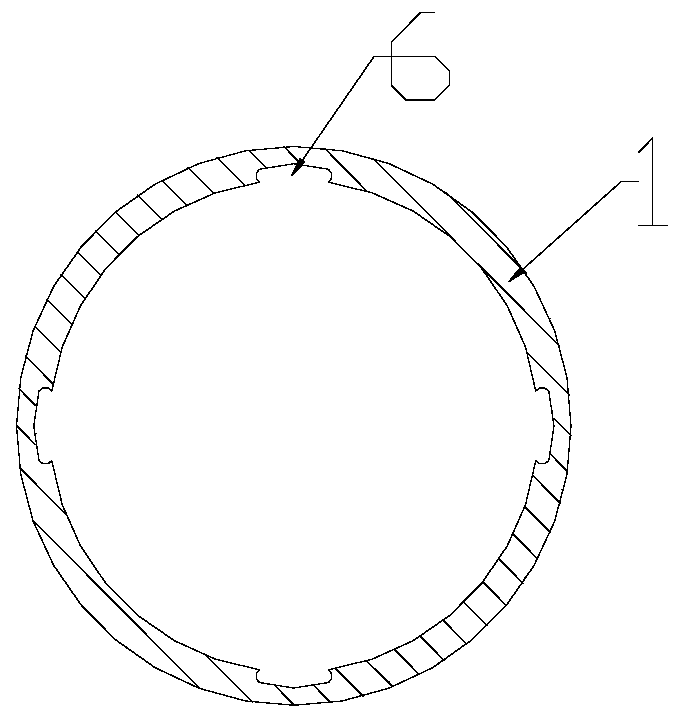

[0028] Such as Figure 1-5 As shown, a wire splicing device includes a conductive connection mechanism. Both ends of the conductive connection mechanism are plugged with wire joints. The conductive connection mechanism includes an outer shell 1 and an inner insulating sleeve 2 threaded on the inner side of the outer shell 1. The inner insulating sleeve 2 There is a conductive component electrically connected to the wire joint inside, the end of the inner insulating sleeve 2 is provided with strip-shaped sliding holes 3 at intervals along the circumferential direction, and a damping ball 4 is slid inside the strip-shaped sliding hole 3, and the inside of the strip-shaped sliding hole 3 The inner diameter is smaller than the diameter of the damping ball 4, and the outer diameter is larger than the diameter of the damping ball 4. The strip-shaped sliding holes 3 on both sides of the damping ball 4 are filled with damping rubber 5. The storage groove 6 for accommodating the dampin...

Embodiment 2

[0033] This embodiment is basically the same as Embodiment 1, the difference is: as Figure 5-6 As shown, the wire joint includes two semicircular tapered conductive sleeves 10 and a wire insulating sleeve 11 set on the outside of the tapered conductive sleeve 10. The inner side of the wire insulating sleeve 11 is provided with a tapered hole that matches the tapered guide sleeve. 12. The inner wall of the conical conductive sleeve 10 is fixed with a piercing contact 13 electrically connected to the wire. One end of the tapered conductive sleeve 10 with a smaller diameter is placed in the tapered hole 12 , and the end with a larger diameter extends out of the tapered hole 12 . Through the cooperation of the tapered hole 12 and the tapered conductive sleeve 10, the tapered conductive sleeve 10 is always pressed against the wire to prevent the wire from falling off, and at the same time avoid the separation of the tapered conductive sleeve 10 and the wire insulating sleeve 11; p...

Embodiment 3

[0041] This embodiment is basically the same as embodiment one or two, the difference is: as Figure 7 and 8 As shown, between the outer shell 1 and the inner insulating sleeve 2 there is a positioning assembly which restricts the rotation of the outer shell 1 evenly in the circumferential direction. The positioning assembly includes a positioning groove 19 arranged on the outer wall of the inner insulating sleeve 2. Telescopic groove 20, the limit block 21 is slidingly arranged in the telescopic groove 20, the limit block 21 is connected with the inner wall of the telescopic groove 20 by the first compression spring 22, the housing 1 is equipped with a positioning rod 23, and the lower end of the positioning rod 23 is provided with a The lower arc-shaped tip 24 is integrally formed with the positioning rod 23 and is placed at the lower end of the limiting block 21 . The side wall of the positioning rod 23 is provided with a slot 25 that cooperates with the limiting block 21 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com