Comprehensive recycling power generating system applicable to purifying dust, dust-removing dust and semi-coke powder

A technology of power generation system and semi-coke powder, which is applied in the field of dust recovery and utilization system, can solve the problems of inability to directly burn comprehensive utilization, low utilization rate, land occupation, etc., to increase social and environmental benefits, reduce pollution, and improve market competition force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is further described in conjunction with the following examples.

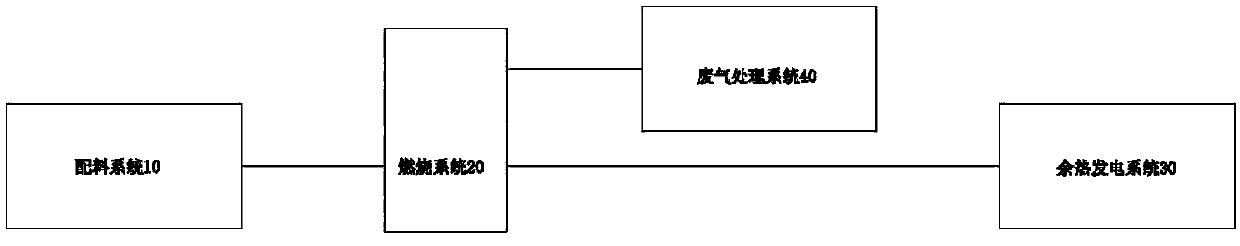

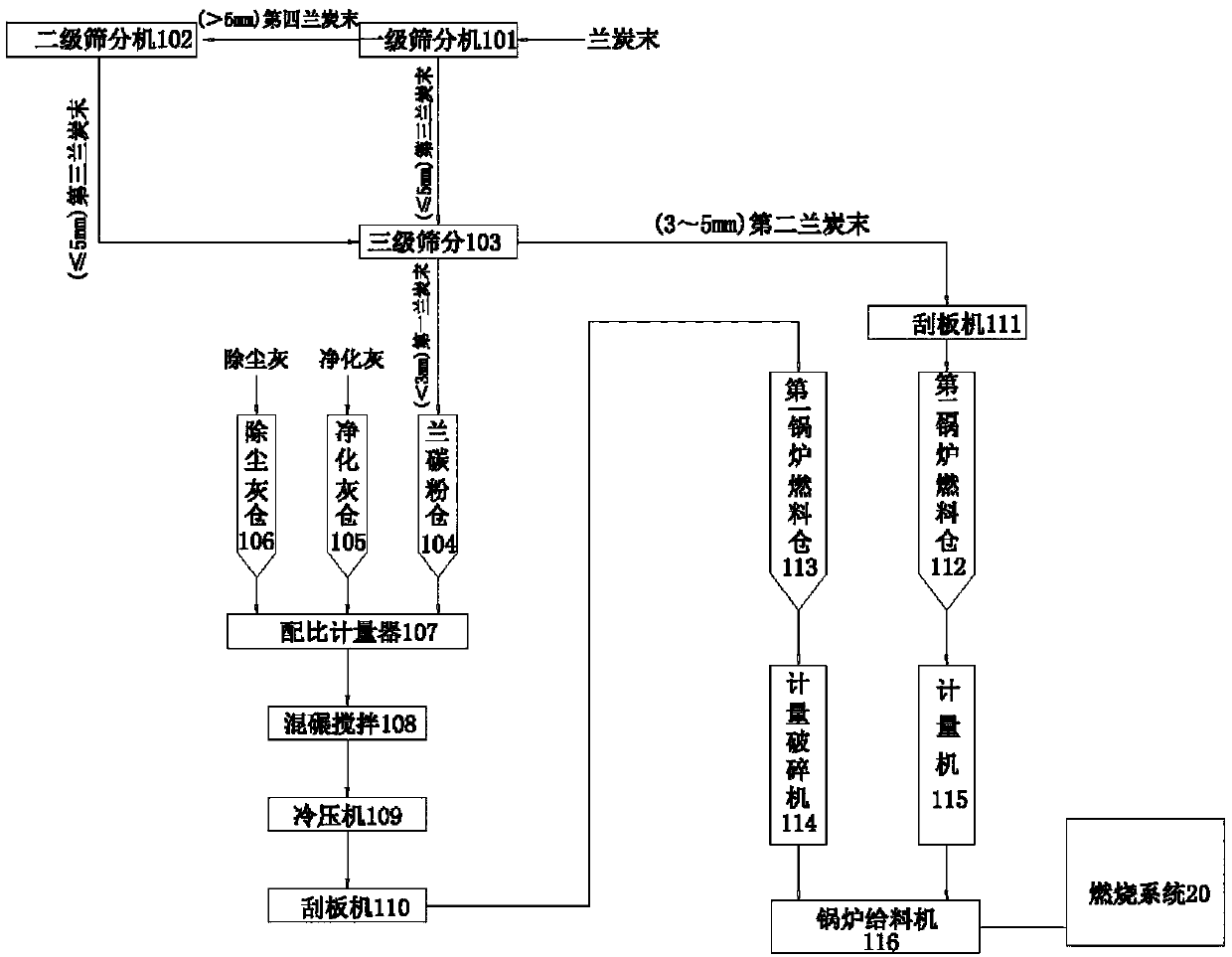

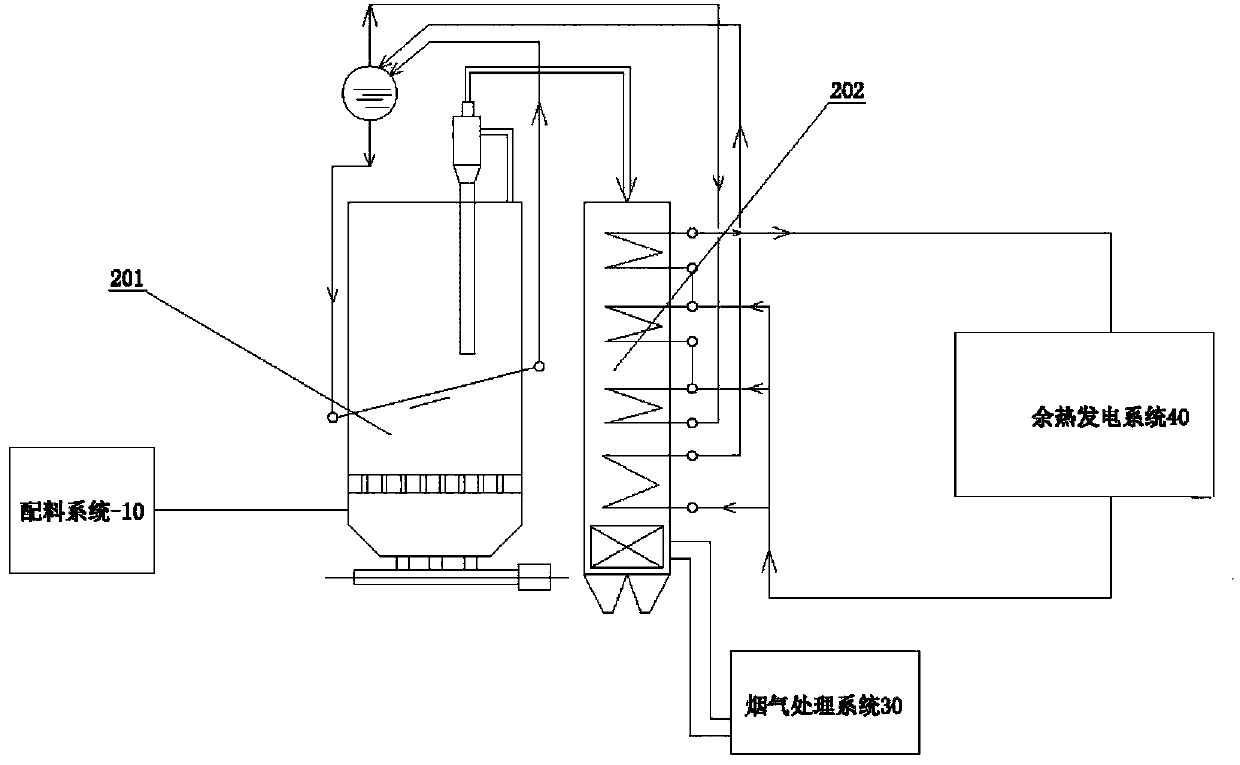

[0031] A specific embodiment of the present application that is applicable to the comprehensive utilization power generation system of purification ash, dust removal ash and semi-coke powder, such as Figure 1 to Figure 5 As shown, including batching system 10 ( figure 2 ), combustion system 20 ( image 3 ), waste heat power generation system 30 ( Figure 4 ) and exhaust gas treatment system 40 ( Figure 5 ), the batching system mixes dust removal ash, purified ash and blue carbon powder to make particles with a particle size less than mm, and transports the particles to the combustion system; the combustion system fully burns the particles equipped with the batching system and produces The superheated steam and waste gas are sent to the waste heat power generation system for power generation, and the waste gas is sent to the waste gas treatment system for waste gas treatment an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com