A subgrade filling construction method utilizing aeolian sand

A construction method and aeolian sand technology, applied in infrastructure engineering, roads, excavation, etc., can solve problems such as difficulty in feeding aeolian sand roadbed, difficult to meet roadbed design requirements, and difficult to become a whole, so as to reduce project costs. , to avoid the rapid evaporation of water, reduce the effect of the existence of dunes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

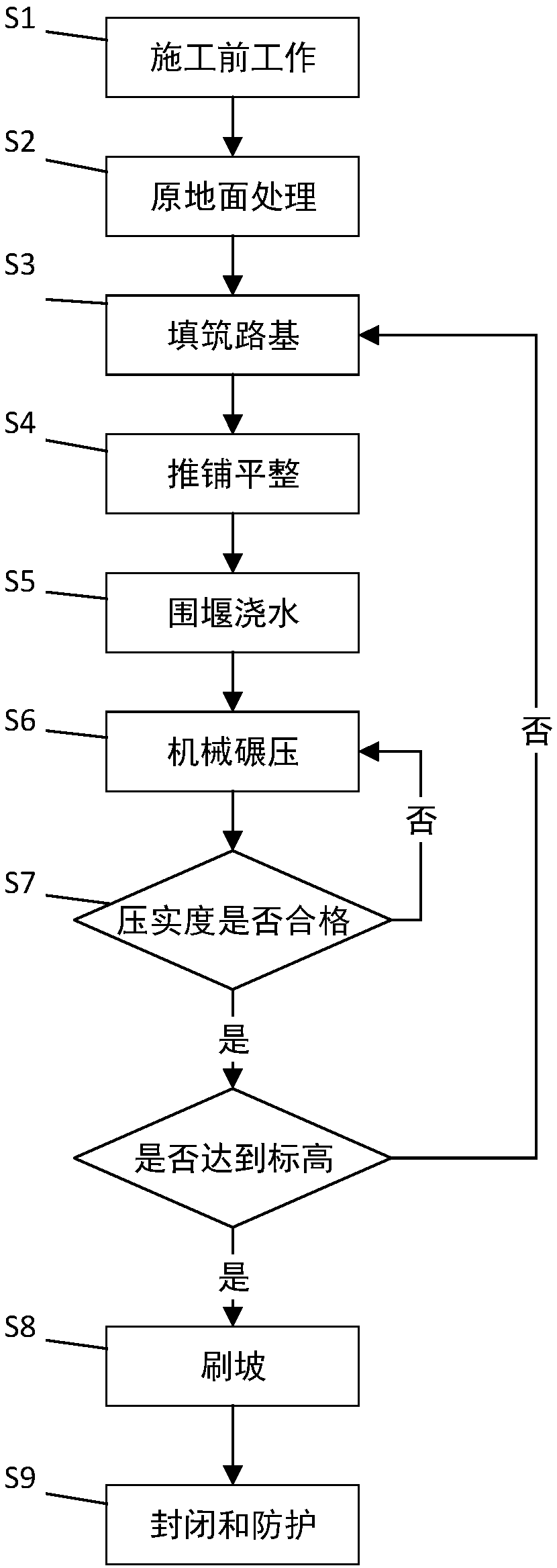

[0033] like figure 1 Shown, a kind of aeolian sand embankment filling construction method comprises the following steps:

[0034] S1. Before construction, make good arrangements for personnel and construction machinery, determine the relative density of aeolian sand filler through sampling tests, and complete the construction measurement and setting-out work;

[0035] S2. Clean the surface of the subgrade, and carry out rolling before filling to meet the set compaction degree standard, and the compaction degree is not less than 95%;

[0036] S3. Fill the single-layer subgrade with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com