Processing technology for high wear-resistant and antibacterial denim fabric

A technology for denim fabrics and processing technology, applied in the field of textile fabrics, can solve the problems of less cleaning times, waste of raw materials, complicated preparation methods, etc., and achieve the effects of improving carbonization efficiency, reducing time, and reducing steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

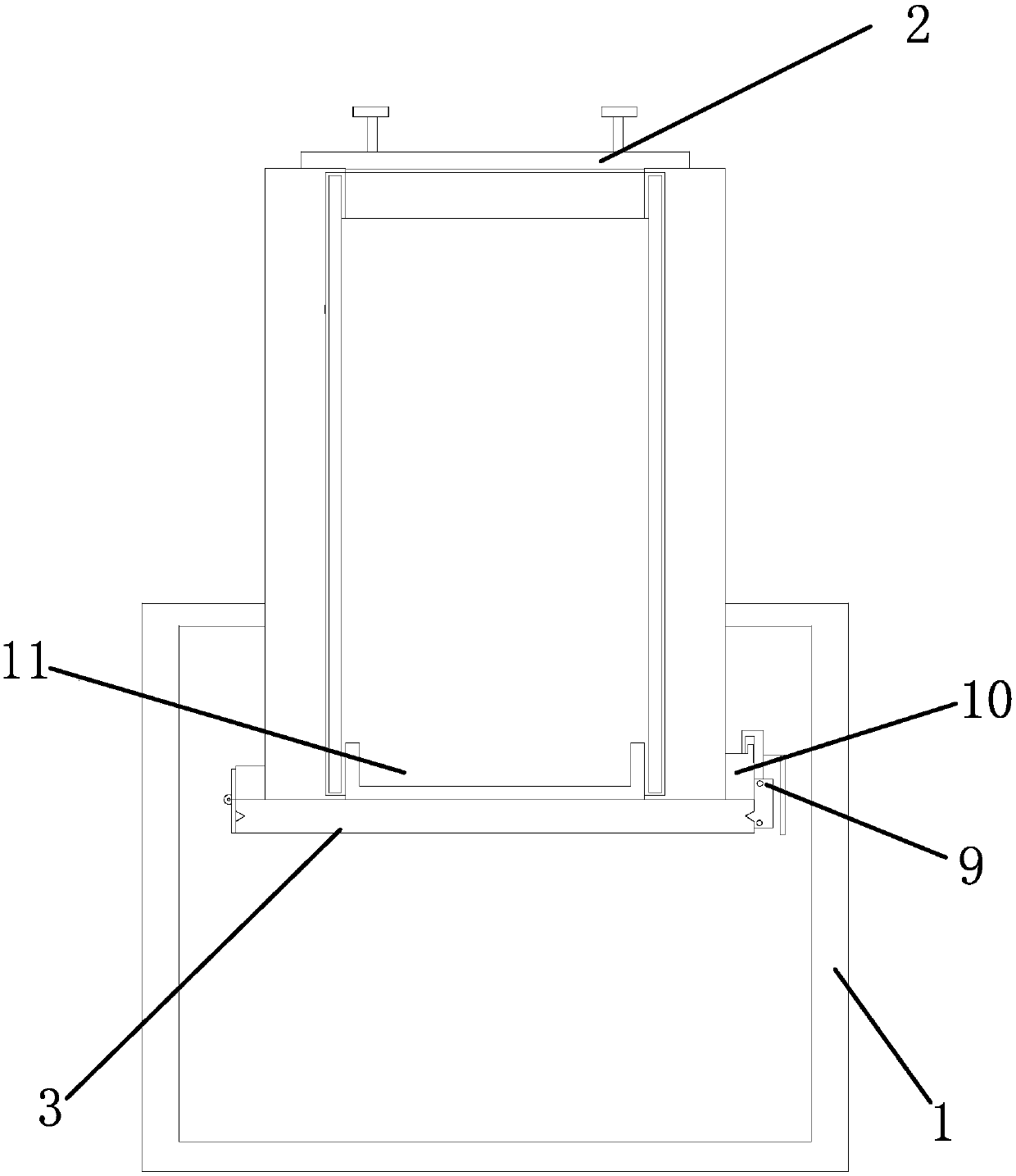

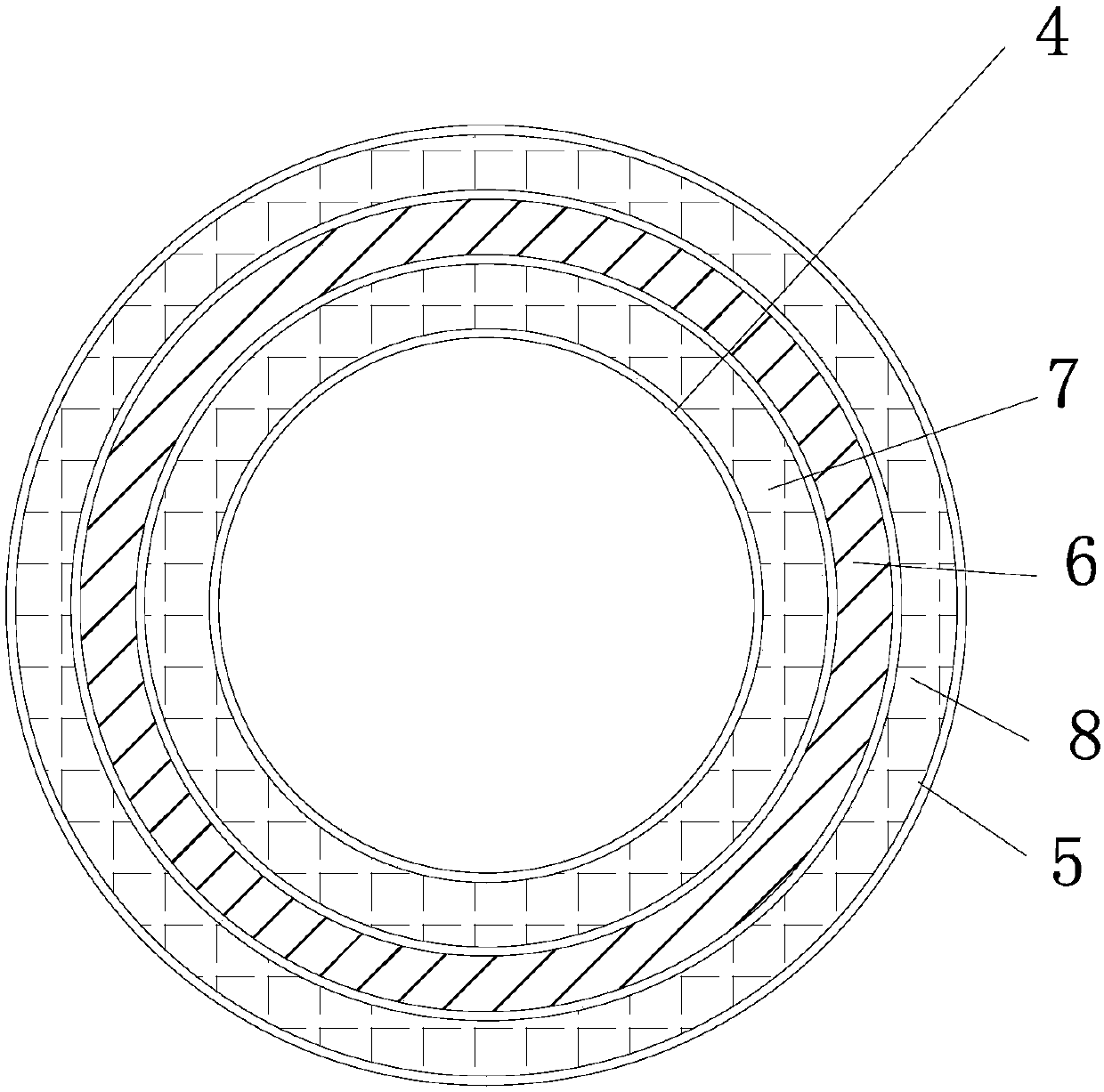

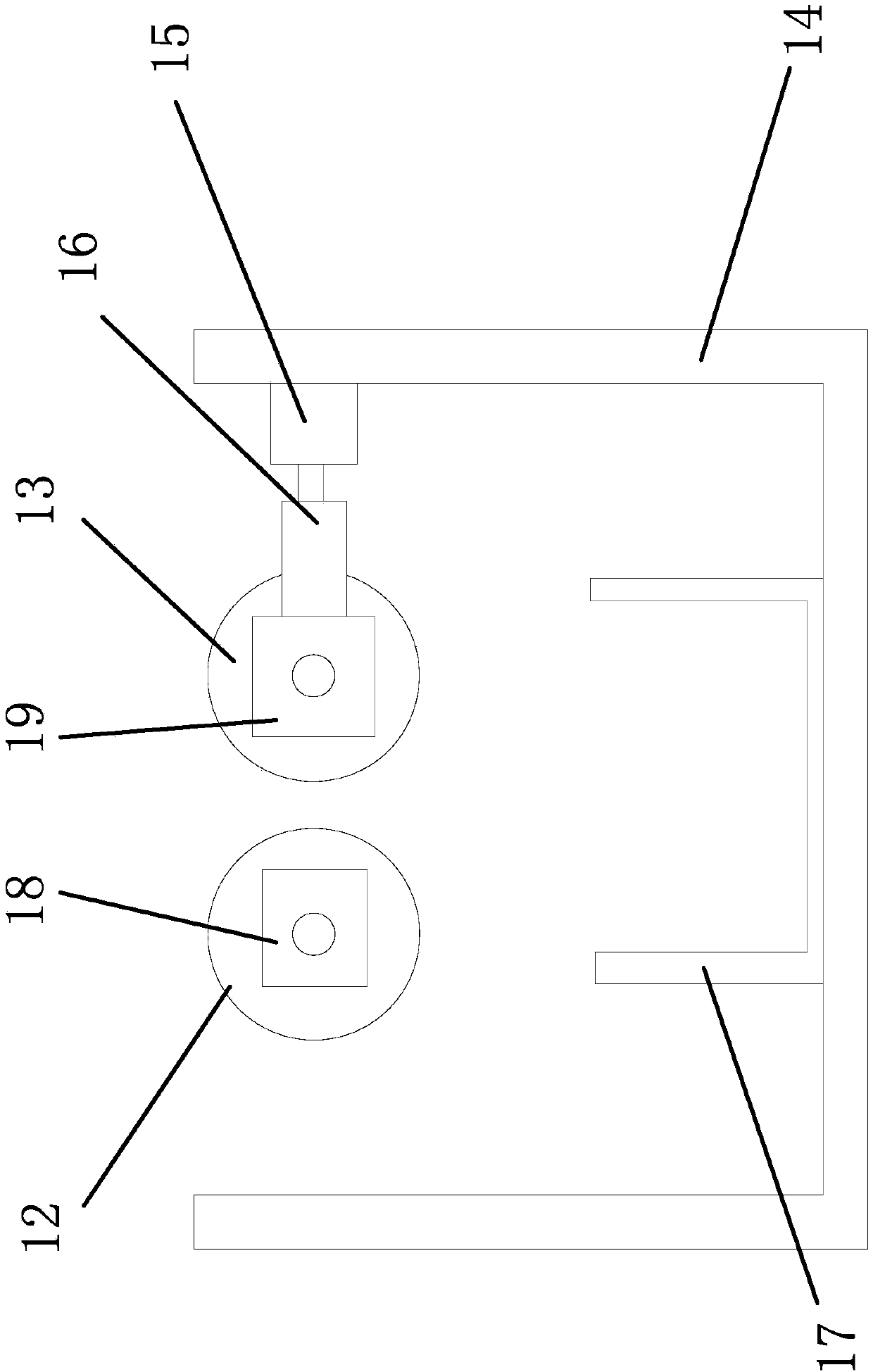

[0051] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0052] A processing technology for high wear-resistant antibacterial denim fabric, comprising the following steps:

[0053] (1), raw material preparation:

[0054] Made from the following raw materials by weight: spandex fiber 12, cotton fiber 15, hemp fiber 16, regenerated fiber 20, wolfberry 10, ginger 2, mugwort leaves 4, wheat straw 15, wood cellulose 5, soybean protein fiber 8, tea tree essential oil 0.4 , calcium carbonate 5, hydrochloric acid 6, Tencel 40, nano zirconia 0.5, paraffin 4, 1-butyl-3-methylimidazole acetate 100, 1-allyl-3-methylimidazole chloride 98, water 30;

[0055] (2) Preparation and preparation of auxiliary raw materials:

[0056] It is made from the following raw materials by weight: 3 flaxsee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com