Multilayer cloth and manufacturing method thereof

A manufacturing method and base fabric technology, applied in the textile field, can solve the problems of easy skewing of sewing lines, poor bulkiness, long labor time, etc., and achieve the effect of avoiding skewed lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

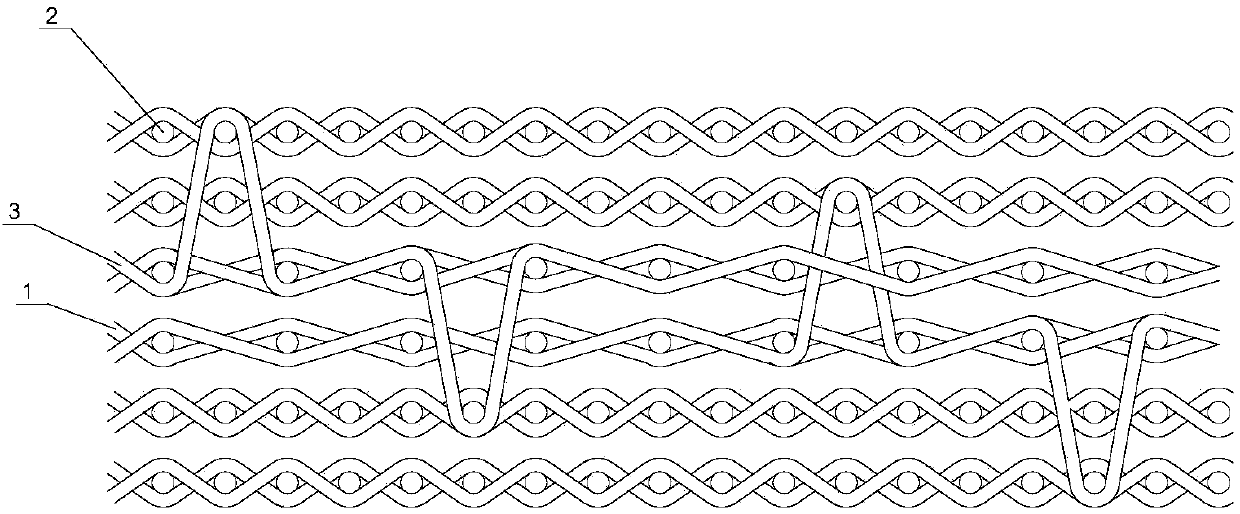

[0044] A multi-layer fabric, including several layers of base fabrics woven by warp yarns and weft yarns, each layer of base fabrics is connected by a connection point, and the connection point is that the warp yarns of the base fabric of this layer bypass the weft yarns of other base fabrics to connect Specifically, the "connection point is the structure in which the warp yarns of the base fabric of this layer bypass the weft yarns of other base fabrics". A connection point, (a connection point does not mean a point, but a structure connected in this way). The connecting warp is connected with other layers every several wefts to form a connecting point, which directly connects the base fabrics of each layer during ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com