Carbonyl reductase mutant, vector, engineering bacterium and application thereof

A technology of genetically engineered bacteria and mutants, applied in the direction of oxidoreductase, bacteria, and microorganism-based methods, can solve the problems of low catalytic efficiency, low concentration of catalytic substrate, low enzyme yield, etc., and achieve excellent catalytic activity, The effect of good app development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

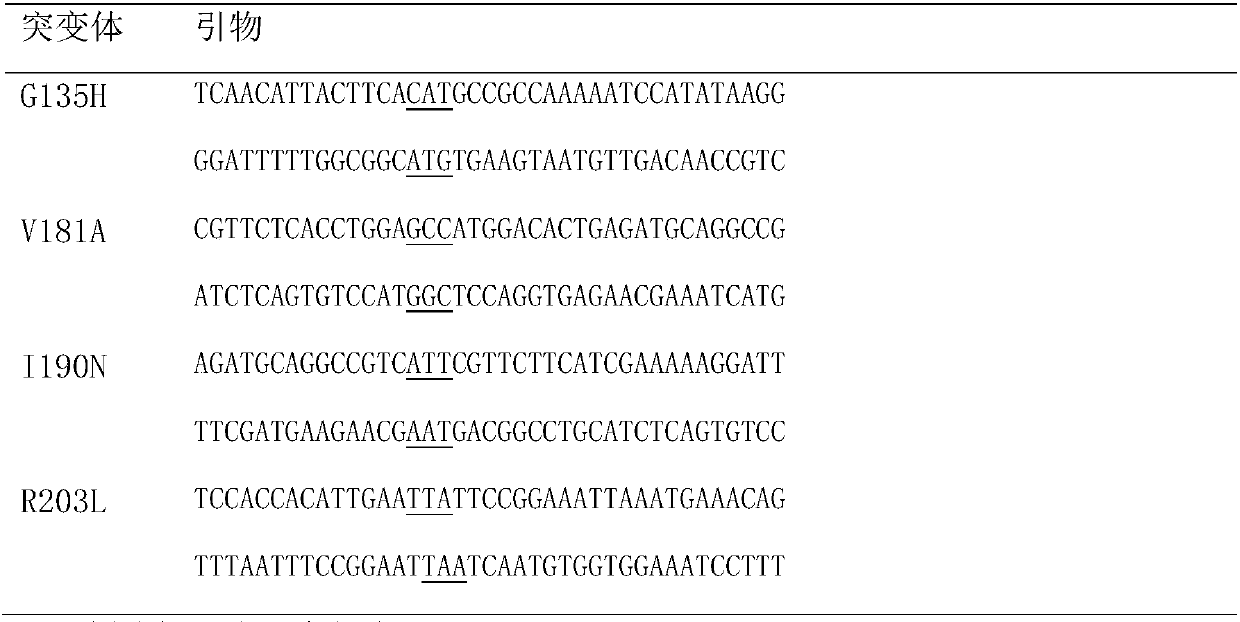

[0036] Example 1: Construction of mutants

[0037] Using the oligonucleotide fragment containing the mutation point as the primer (Table 1), the QuickChangeTM method (Stratagene, La Jolla, CA) was used to amplify the pET-30a recombinant plasmid containing the carbonyl reductase gene.

[0038] Table 1 Mutants to construct primers

[0039]

[0040] a The underline indicates the mutation site

[0041] PCR reaction system: 5×PrimerSTAR buffer(Mg 2+ plus), 5μL; dNTPs (2.5mM each), 2.0μL; upstream primer (10μM), 1.0μL; downstream primer (10μM), 1.0μL; recombinant plasmid template, 15ng; PrimerSTARpolymeraseTM HS (2.5U / μL), 0.5μL ; Add ddH 2 O to a total volume of 25μL.

[0042] PCR program: (1) 98°C, 1min; (2) 98°C, 10s; (3) 55°C, 10s; (4) 72°C, 7min. Steps (2)-(4) are cycled 20 times and then cooled to 4°C.

[0043] After the PCR product is washed, it is digested with the restriction enzyme DpnI that specifically recognizes the methylation site to degrade the template plasmid. Enzyme diges...

Embodiment 2

[0046] Example 2: Induced expression of carbonyl reductase mutants

[0047] The engineered bacteria constructed in Example 1 were inoculated into 50μg / mL kanamycin LB medium, cultured overnight at 37°C and 200 rpm, and then inoculated to 50μg / mL kanamycin at 1% inoculum amount (v / v) In LB medium, culture at 37°C and 200rpm until the cell concentration OD600 is about 0.6, add IPTG with a final concentration of 0.1mM, induce culture at 26°C for 6h, centrifuge at 4°C, 8000rpm for 10min to collect the cells, store at -80°C spare.

Embodiment 3

[0048] Example 3: Fermenter culture of carbonyl reductase mutant

[0049] The engineered bacteria constructed in Example 1 were inoculated into 50μg / mL kanamycin LB medium, cultured overnight at 37°C and 200 rpm, and then inoculated to 50μg / mL kanamycin at 2% inoculum (v / v) Cultivate in the medium at 37°C at 200 rpm, and inoculate 10% inoculum (v / v) into the fermentor containing 15L of 50μg / mL kanamycin fermentation medium in the middle logarithmic phase at 37°C. About 14h (in the late logarithmic period), add lactose for induction for 20h, and collect the bacteria by centrifugation in a tube centrifuge for use.

[0050] The fermentation medium used in Example 3 is a well-known medium in the art that can grow mutants and produce the carbonyl reductase mutant protein of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com