Board punch with adjustable saw blade radian

An adjustable and punching machine technology, applied in circular saws, sawing equipment, wood processing appliances, etc., can solve the problems of inconvenient adjustment and high cost, and achieve improved adjustment convenience, good structural stability, and mechanism flexibility. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

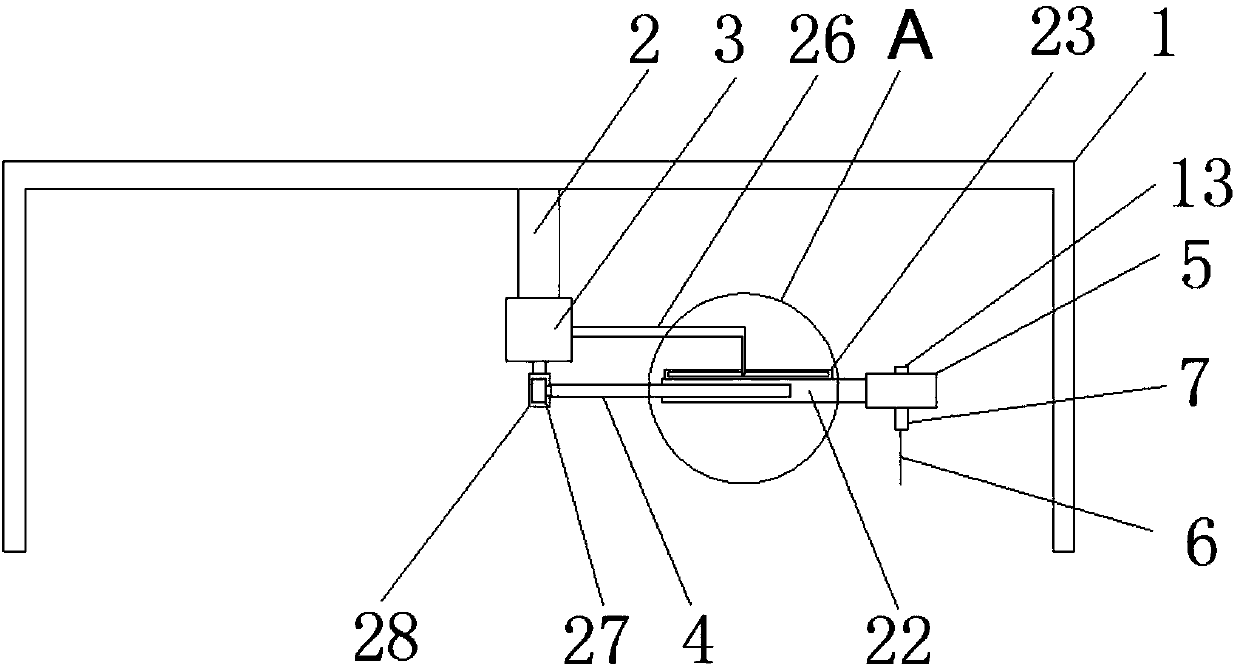

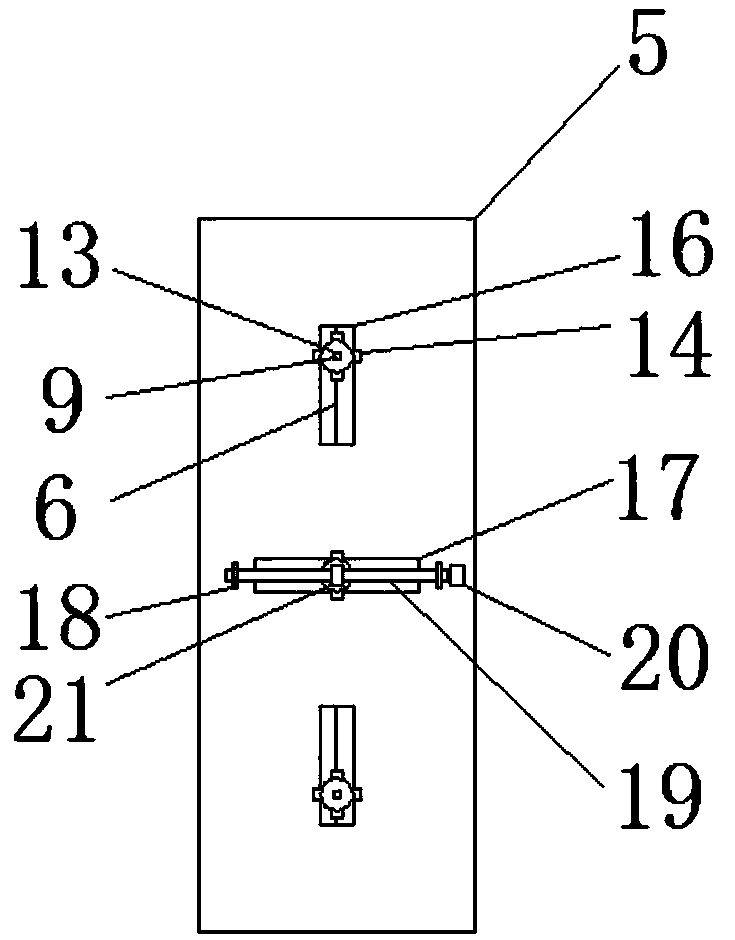

[0015] Example. A wood punching machine with adjustable saw blade radian, which is composed of Figures 1 to 4 Shown, comprise gantry 1, the bottom of gantry 1 beam is connected with hydraulic cylinder 2; The bottom of hydraulic cylinder 2 is connected with rotating motor 3, and one side of rotating motor 3 bottom is connected with threaded rod 4; Threaded rod 4 is connected with saw The blade frame 5 is connected with an elastic saw blade 6 on the blade frame 5 .

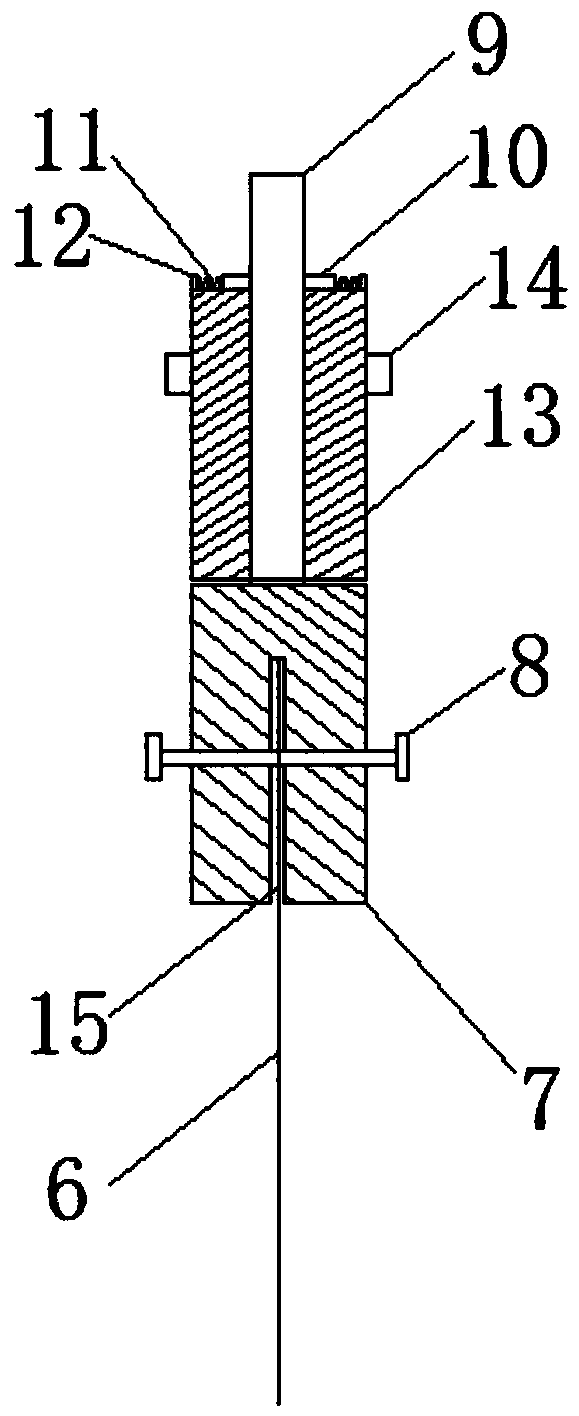

[0016] The upper end of the elastic saw blade 6 is connected with a plurality of saw blade clamps 7, and each saw blade clamp 7 is threadedly connected with a screw 8; are fixedly connected with a fixed block a10; each fixed block a10 is fixedly connected with a spring 11, and one end of the spring 11 is fixedly connected with a fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com