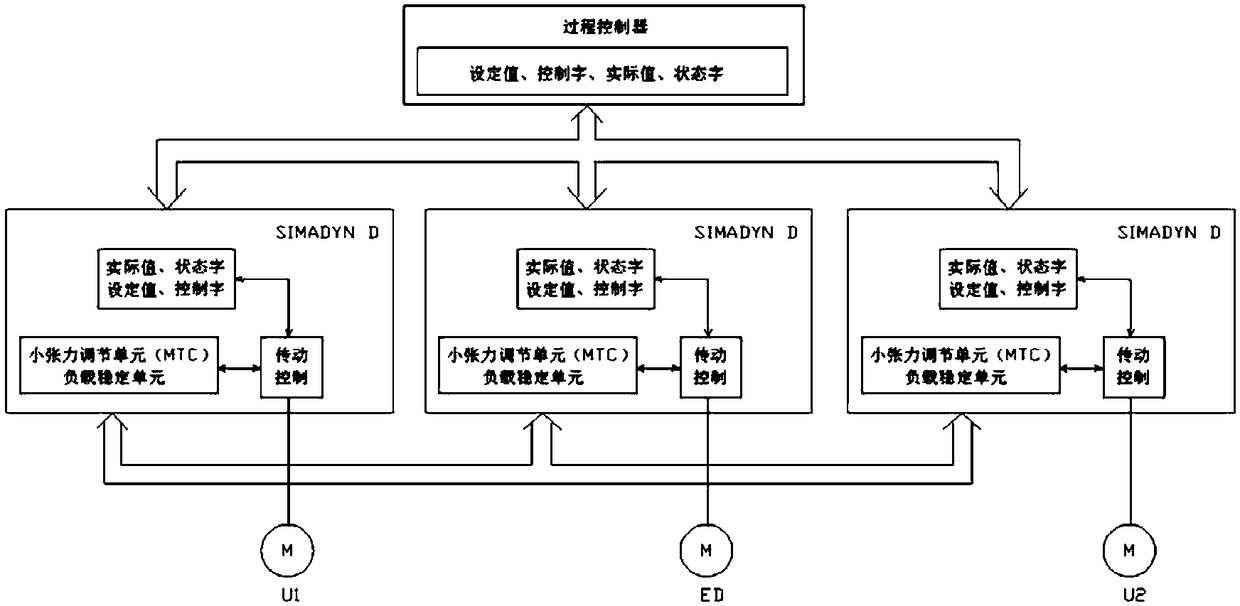

A Control System for Switching and Cutting of Small Tension Regulator in Roughing Mill

A technology of tension regulator and roughing mill, applied in the direction of tension/pressure control, etc., can solve the problem of wrong pick-up and failure of universal roughing mill, failure of small tension control system to operate normally, and failure of small tension regulator of universal roughing mill. Cut control errors and other problems to achieve logical and accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

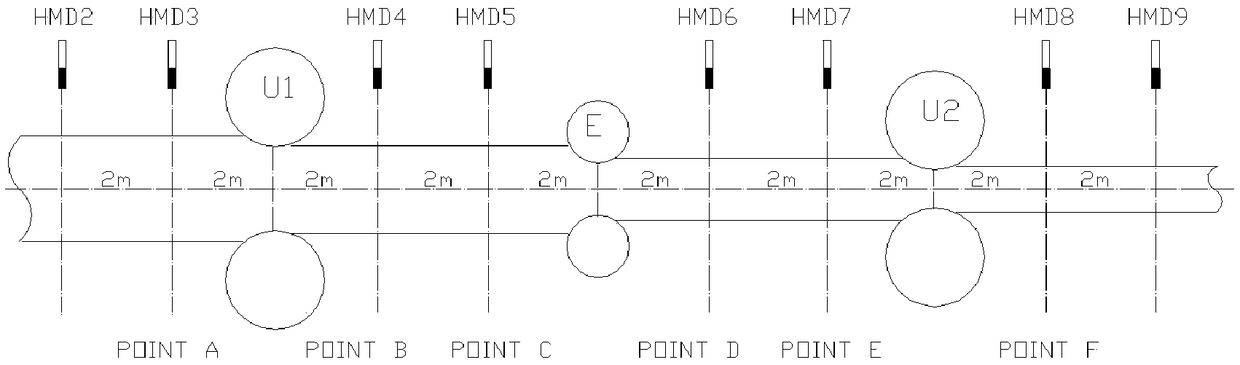

[0031] For the existing profile steel universal roughing mill, in order to facilitate the biting of the rolled pieces of each stand in the universal roughing mill, the three stands of the universal roughing mill are usually threaded and rolled at a low speed. In this embodiment, it can be known from the specific speed of the mill , The rolling rules of the universal rough rolling mill for profiled steel show that the forward and reverse threading mill speed of the universal rough rolling mill of this embodiment is usually about 2 m / s. In this way, based on the fact that the dynamic response time of each rack of the unit to the impact of the rolling piece bite is about 0.3 seconds and the distance between each rack in the unit is 6 meters, it can be achieved through the rack on-load signal (such as the actual current of the main drive motor of the rack). (more than 10% of the rated motor current) plus time delay to obtain the position signal of the head of the rolled piece durin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com