Feeding cold rolled tube slewing device

A technology of rotary device and cold-rolled pipe, applied in the direction of driving device for metal rolling mill, metal rolling, metal rolling, etc., can solve the problems of complex structure and complex structure of the driving mechanism, and achieve simple structure, low cost, Easy to install and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

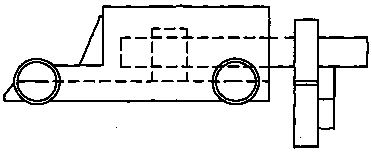

[0009] Such as figure 1 As shown, the technical solution of the present invention is: a rotary device for feeding cold-rolled pipes, including a trolley, a fixed unit, a basic unit and a dragging structure, characterized in that the output end of the basic unit is installed on the dragging structure, The fixed frame is installed on the vehicle body, the dragging structure is installed on the fixed unit, and the input end of the basic unit is connected to the output end of the power mechanism through transmission.

[0010] Finally, it should be noted that the above embodiments are only used to illustrate the technical solutions of the present invention rather than limit the protection scope of the present invention. Although the present invention has been described in detail with reference to the preferred embodiments, those of ordinary skill in the art should understand that Modifications or equivalent replacements are made to the technical solutions of the present invention w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com