Kelp harvesting and sorting method and robot

A robot and finishing machine technology, applied in the fields of harvesters, agricultural machinery and implements, applications, etc., can solve the problems of hard work and high labor intensity, and achieve the effect of simple process, high work efficiency, continuous unbuttoning and harvesting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

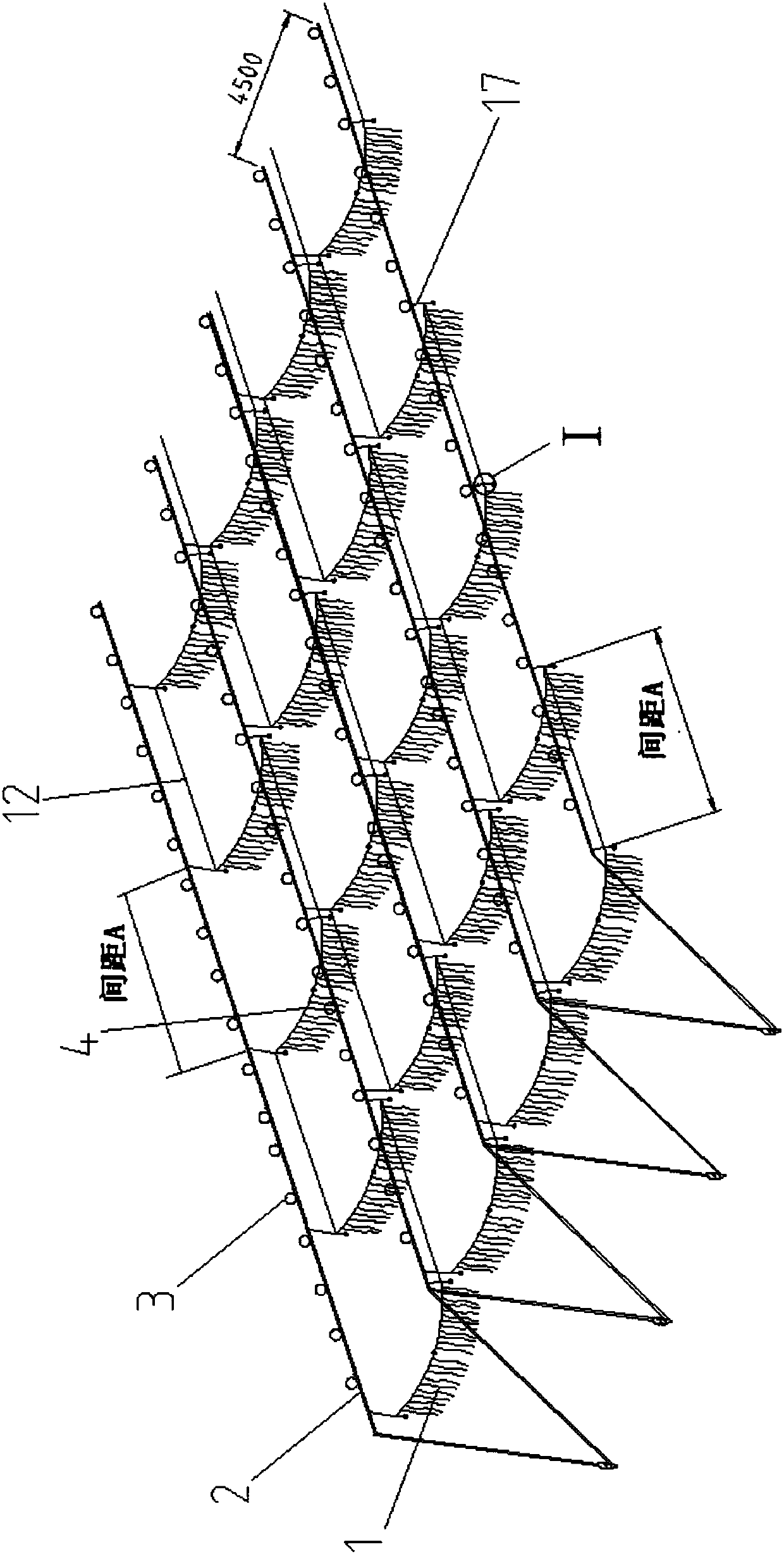

[0027] Such as figure 1 Shown: the connection mode of kelp growing rope 4, the length is 4-5 meters and the growing rope 4 attached to kelp is arranged vertically and horizontally, and the connecting rope 12 is connected to the two ends of the growing rope one by one at intervals in order, and the growing rope and Connect the ropes in series. One end of hoisting rope 17 is consolidated with growing rope and connecting rope, and the other end is connected with buoy 2, and the middle part of hoisting rope is connected by rope buckle 18, which is convenient for taking off and harvesting. The length of the float is 70-100 meters, which can be cultivated in multiple rows;

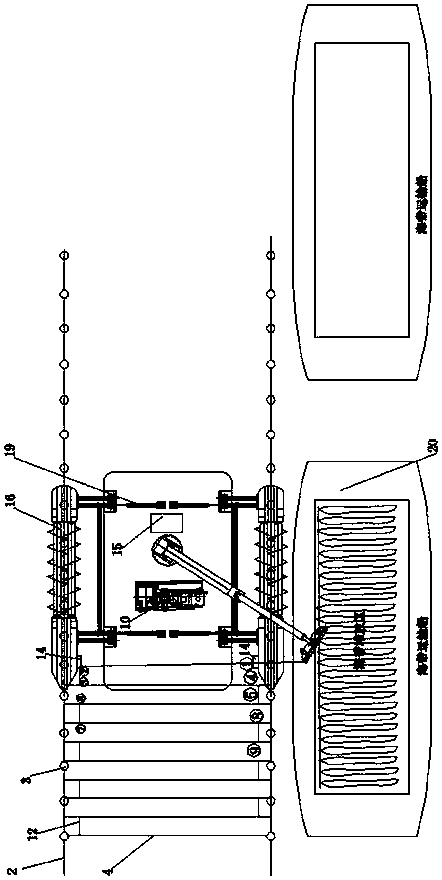

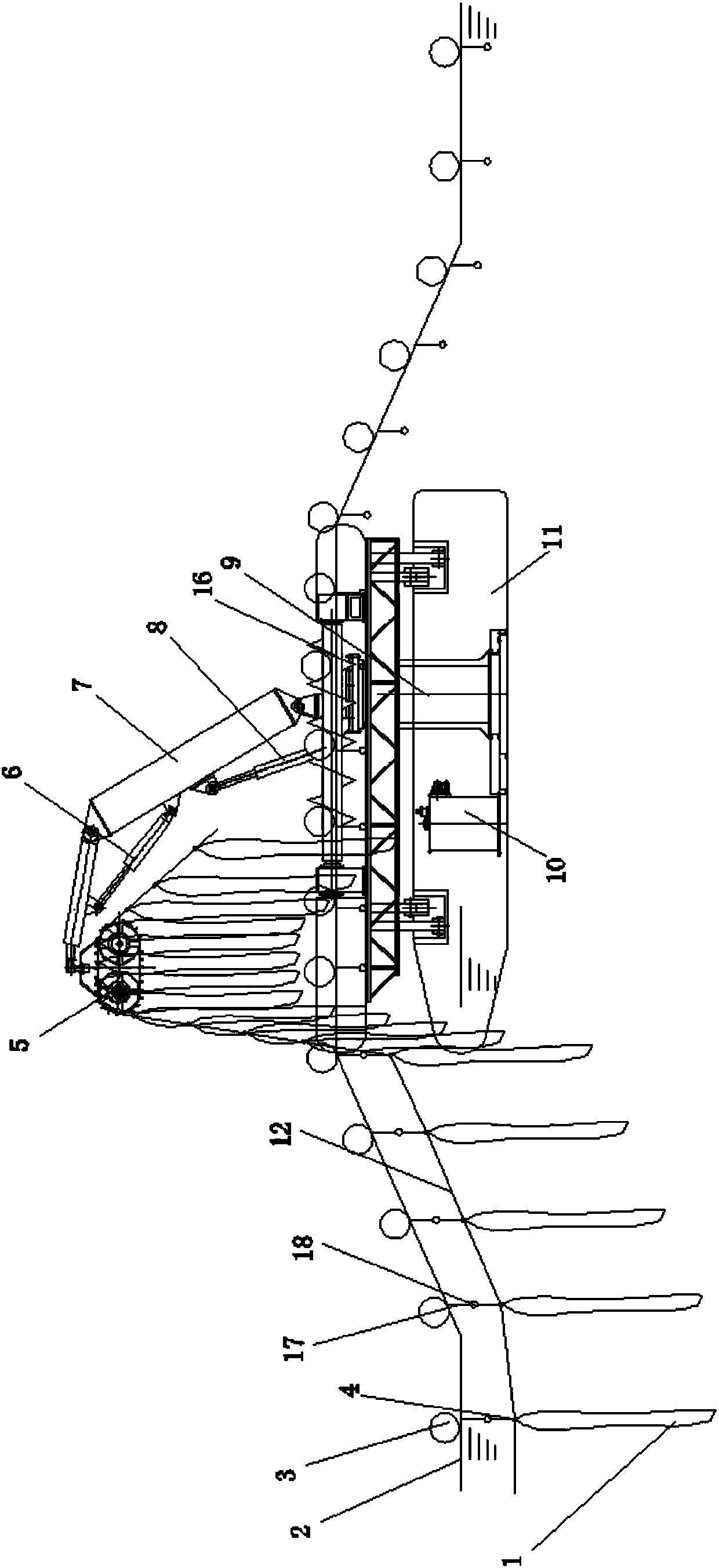

[0028] see Figure 1-4 , a kelp harvesting and sorting robot, comprising a liftable floating body 11, the two sides of the floating body 11 are respectively connected with a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com