Low NOX combustion system for travelling grate pelletizing plants

A technology of burners and combustion chambers, applied in the direction of burners, combustion chambers, combustion methods, etc., can solve the problem of increasing the amount of cold primary air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

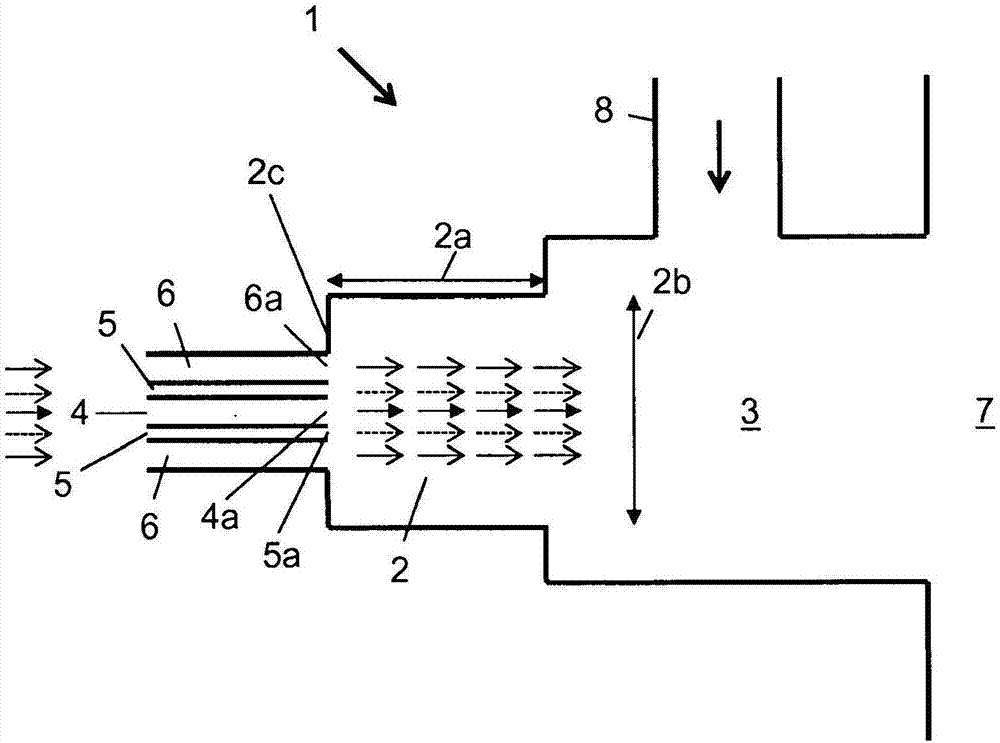

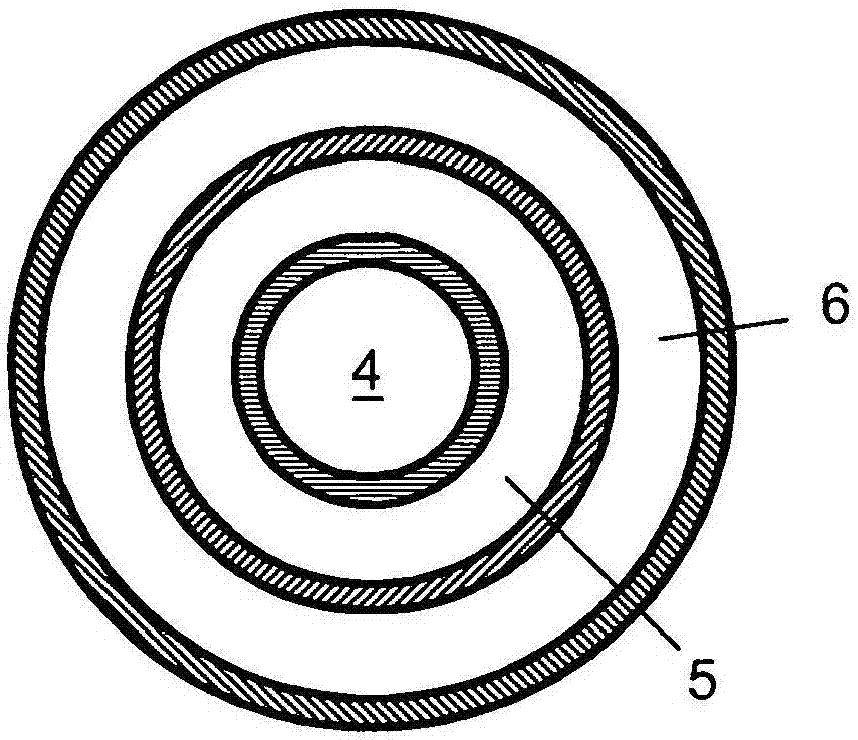

[0041] exist figure 1 In , a burner assembly 1 according to a preferred embodiment of the present invention is shown in cross-section. The burner assembly 1 has a front chamber 2 , a combustion chamber 3 and a fuel inlet pipe 4 , a primary air inlet pipe 5 and a preheated air inlet pipe 6 . These inlet ducts respectively comprise respective fuel inlets 4a, primary air inlets 5a and preheated air inlets 6a.

[0042] A combustion chamber 3 is arranged adjacent to and downstream of the antechamber 2 , the combustion chamber itself being connected to a furnace 7 downstream of the combustion chamber 2 . Furthermore, a combustion air inlet, ie a downcomer 8 , is provided as an inlet to the combustion chamber 3 for introducing combustion air. The vestibule itself has a vestibule length 2a and a vestibule diameter 2b, wherein the length 2a is greater than the diameter 2b. Therefore, the antechamber of the present invention is expected to be smaller than a standard pre-chamber.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com