In-built structure of wheel hub

A technology of built-in and hub, applied in the field of vehicles, can solve the problems of increased rotational inertia of the hub, increased unsprung mass of the car, and low motor efficiency, and achieves the effects of weight reduction, low heat generation, and high motor efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

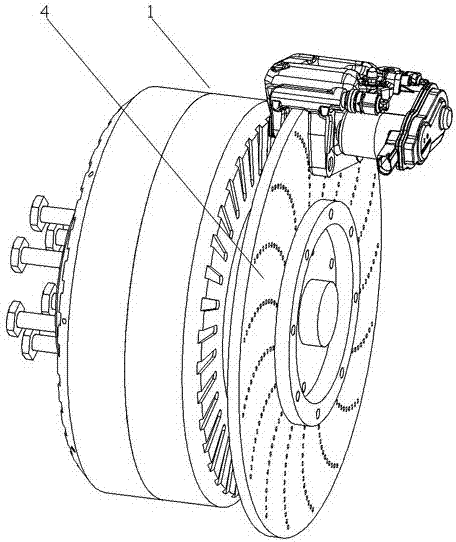

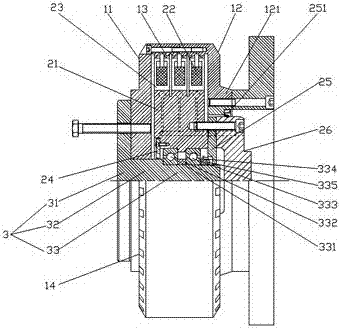

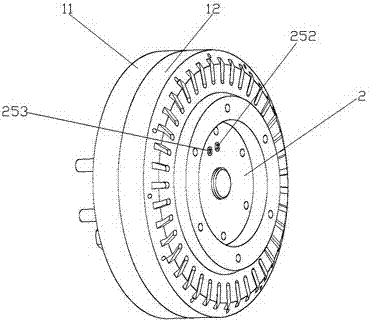

[0026] like Figure 1 to Figure 5 As shown in , a hub built-in structure, including

[0027] Motor and brake disc 4. The motor includes a rotor 1, a stator 2, and a rotating shaft 3. The stator is located in the rotor. The rotor is formed by connecting the first rotor 11 and the second rotor 12. The rotating shaft is fixed by the connecting shaft 31, the supporting shaft 32 and the stator. The shafts 33 are connected sequentially, the first rotor is provided with a positioning hole, the connecting shaft is connected with the first rotor, the supporting shaft passes through the positioning hole, the fixed shaft of the stator is connected with the stator in rotation, and the brake disc is connected with the rotor; the stator includes a stator bracket 21 and a number of iron core groups, the iron core group includes windings 22 and several U-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com