A Finite Element Parametric Modeling Method for Seamed Sandwich Panels

A parametric modeling, sandwich panel technology, applied in electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as optimal design of difficult-to-sew composite sandwich panels, complex sandwich panels, etc. , to shorten the modeling cycle, improve unit quality, and improve analysis efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

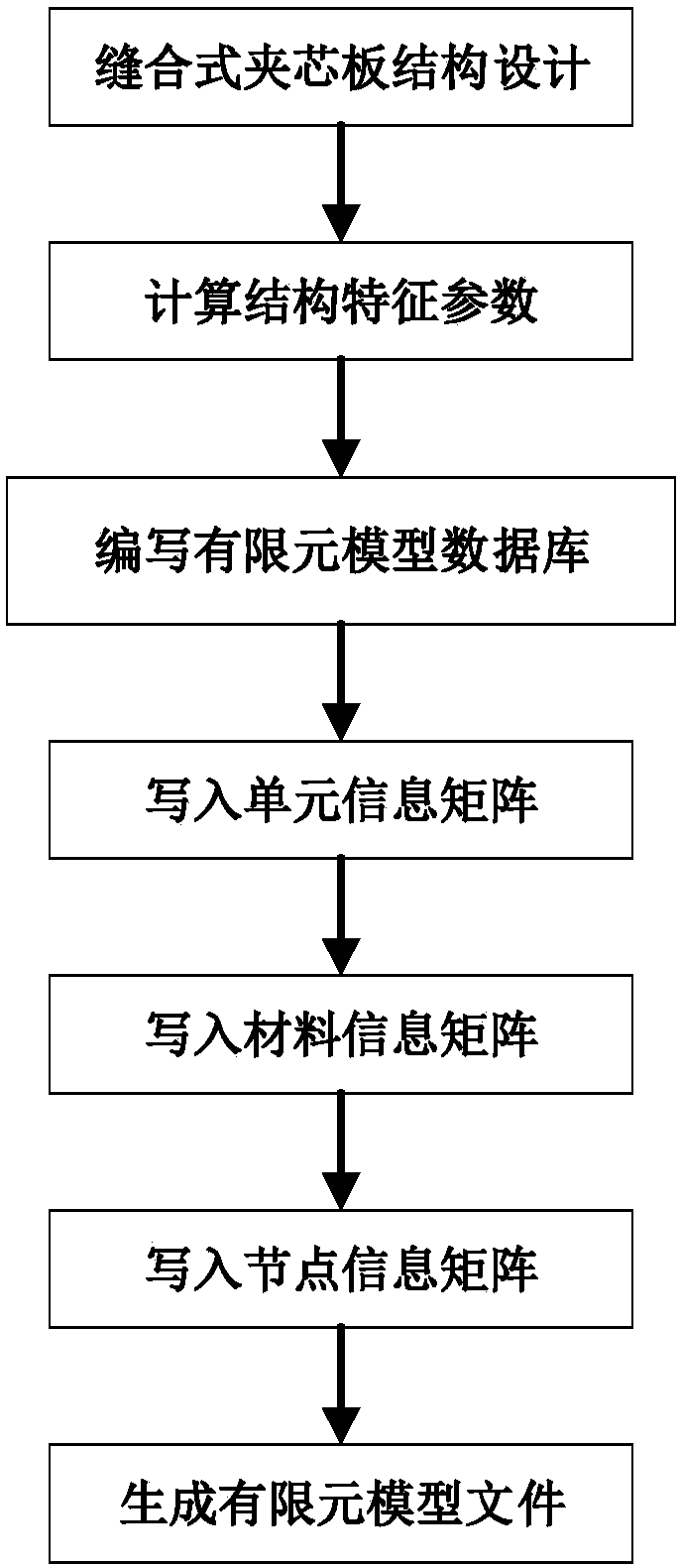

[0031] Such as figure 1 As shown, the present invention provides a finite element parametric modeling method for stitched sandwich panels, comprising the following steps:

[0032] (1), obtaining the geometric characteristic parameters of the stitched sandwich panel;

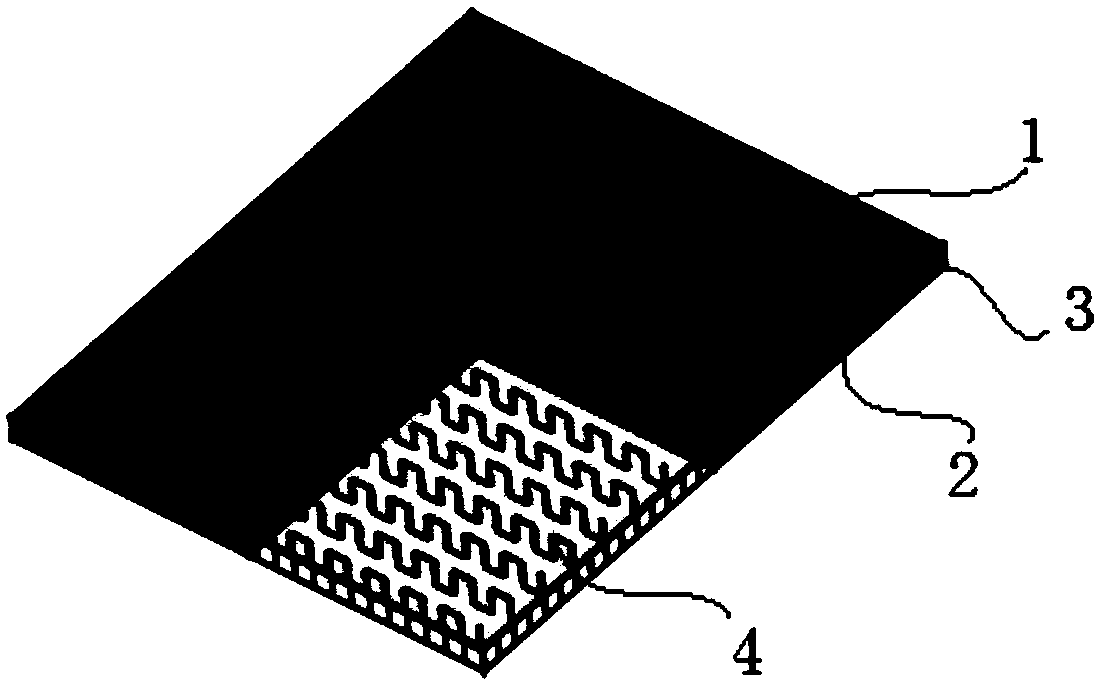

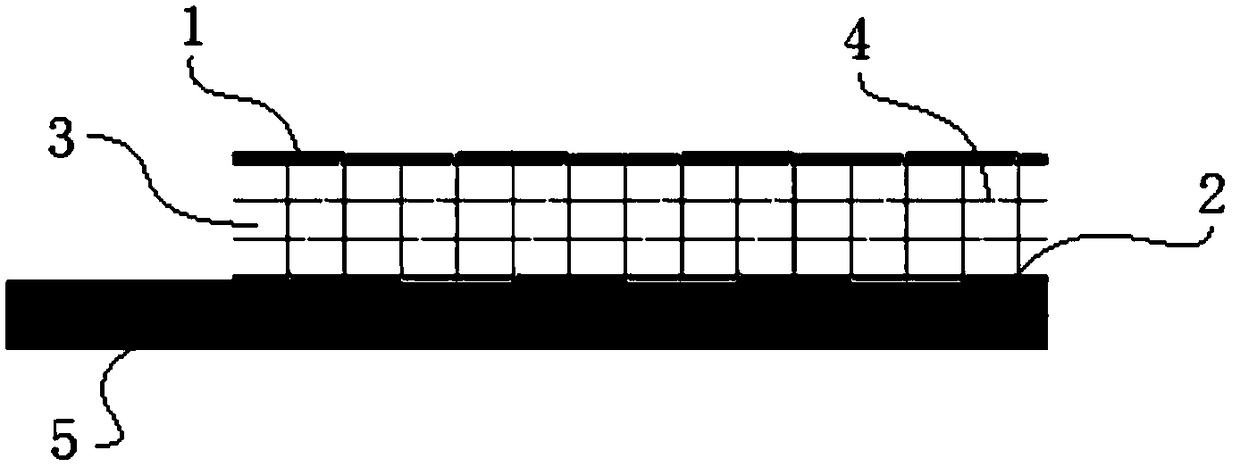

[0033] Such as figure 2 As shown, the stitched sandwich panel includes an upper panel 1, a lower panel 2 and a sandwich layer 3 in the middle, the sandwich layer 3 is bonded to the upper panel 1 and the lower panel 2 through an adhesive layer, and a seam 4 Stitched together; the geometric size of the stitched sandwich panel is selected as 250mm×300mm×12mm, that is, the length of the stitched sandwich panel is L=250mm, width W=300mm, thickness H=12mm, and the thickness of the upper panel is h 1 1mm, the thickness of the lower panel h 2 1mm, the thickness of the sandwich layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com