A test device for simulating tunnel excavation and unloading

A technology of tunnel excavation and test equipment, which is applied in the direction of measuring equipment, instruments, scientific instruments, etc., can solve the problems of uneven melting degree, differential distribution and insufficient stress performance of surrounding rock, and achieve rigidity that is not easily deformed, high rigidity, Construct simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

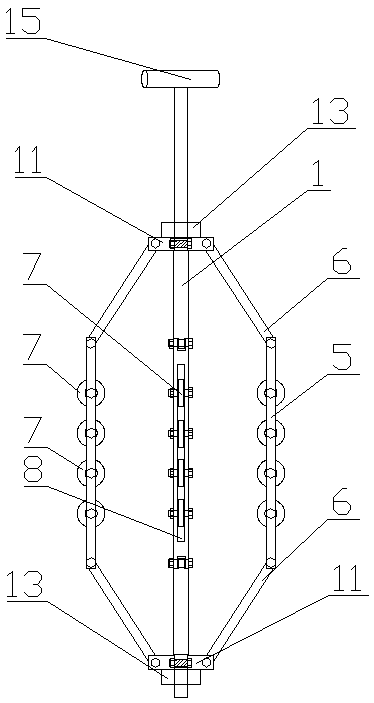

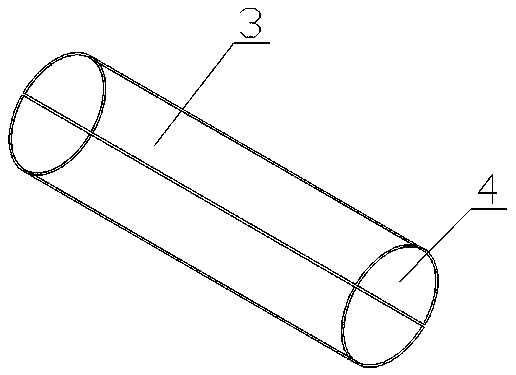

[0042] like figure 1 , 2As shown, a test device for simulating tunnel excavation and unloading includes a central axis 1, a support structure 2 and a steel pipe sheet 3. The steel pipe sheet 3 is an arc-shaped sheet and there are more than two pieces. The inner wall of the tunnel is compatible, and more than two pieces of steel pipe sheets 3 are sequentially attached to the inner wall of the tunnel to be simulated, and a cylindrical inner cavity 4 is formed between more than two pieces of steel pipe sheets 3; the central axis 1 is set on a cylindrical At the central axis of the inner cavity 4, the supporting structure 2 includes a connecting rod 5 and a supporting rod 6 respectively connected to both ends of the connecting rod 5, wherein the connecting rod 5 is fixedly installed on the central axis 1 through the supporting rod 6, and the connecting rod 5 is also installed Bearing 7 is arranged, and bearing 7 is connected with the inner pipe wall sliding support of steel pipe ...

Embodiment 2

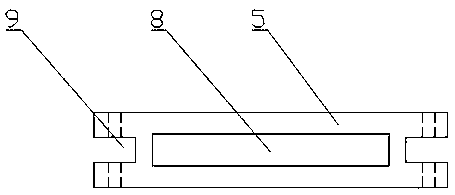

[0045] like figure 1 , 3 As shown, compared with Embodiment 1, this embodiment optimizes the connecting rod 5, and a bearing installation through hole 8 is opened along the shaft of the connecting rod 5, and there are more than two bearings 7, which are arranged in sequence and installed in the bearing installation through hole 8 Inside.

[0046] In this embodiment, multiple bearings 7 can achieve unloading more stably, and at the same time, by opening bearing installation through holes 8, multiple bearings 7 can be installed more neatly, avoiding the problem of large levelness errors between bearings 7 .

Embodiment 3

[0048] like image 3 , 4 , 6, compared with Embodiment 1, this embodiment optimizes the connection between the connecting rod 5 and the supporting rod 6, the two ends of the connecting rod 5 are provided with limiting grooves 9, and the connection between the supporting rod 6 and the connecting rod 5 A limiting block 10 is provided, and the limiting block 10 is located in the limiting groove 9 and is fixedly connected to the connecting rod 5 and the limiting groove 9 by bolts and nuts.

[0049] In this embodiment, the support rod 6 and the connecting rod 5 are fixedly connected together by bolts and nuts, and at the same time, it is also possible to adjust the angle between the support rod 6 and the connecting rod 5 in order to adapt to the size of the inside of the simulated tunnel. To change the position of the connecting rod 5 relative to the central axis 1, when adjusting, it is only necessary to loosen the nut, then adjust the angle, and after the angle is adjusted, tigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com