Biodegradation method of enteromorpha polysaccharide

A technology of prolifera polysaccharide and prolifera, which is applied in the direction of color/spectral property measurement, fermentation, etc., can solve the problem that there is no very effective method for the degradation of prolifera polysaccharide, and can achieve no by-products, short reaction time and mild action conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

[0034] Weigh 0.05g of Enteromorpha crude polysaccharide and add 5mL pH of 5.0 acetic acid-sodium acetate buffer amylase solution, add 5mL100U / mL amylase solution, reaction time 2h, reaction temperature 50 ℃, solid-liquid ratio 1:2000 (enzyme concentration 50U / mL), the enzymolysis solution after enzymolysis was boiled for 5min, and the enzyme was removed by centrifugation. Clearing effect.

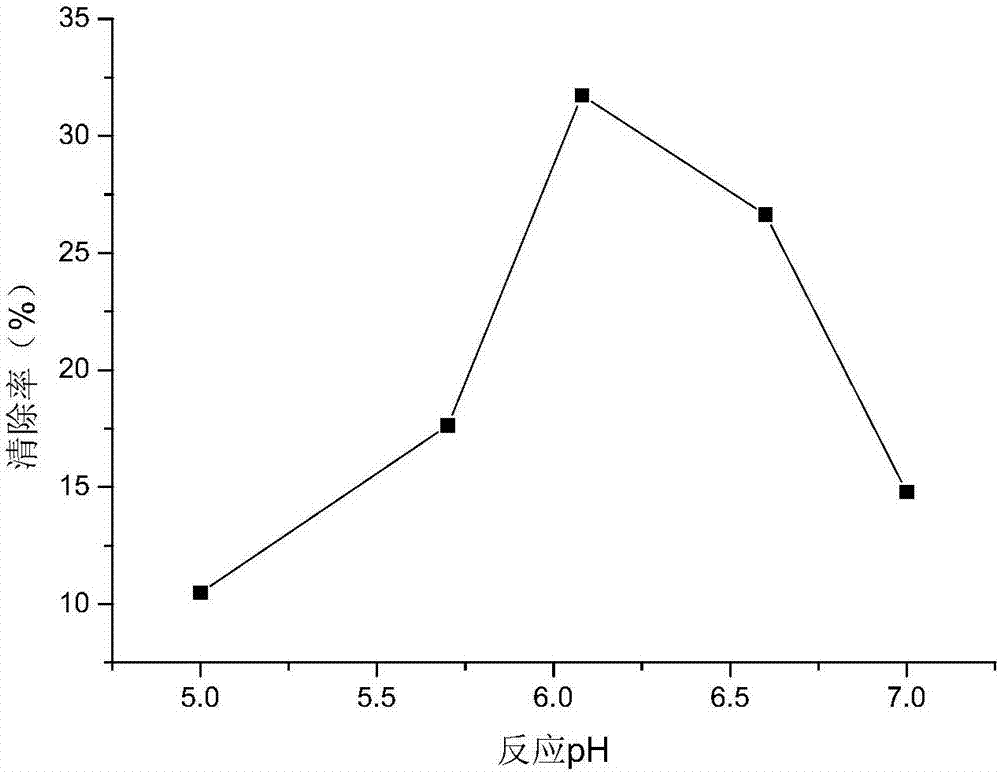

[0035] Change the reaction pH in Example 1-1 from 5.0 to 5.5, 6.0, 6.5, 7.0 respectively, and the rest are the same as Example 1-1 to obtain Examples 1-2, 1-3, 1-4, and 1-5.

[0036] The degraded enteromorpha polysaccharide obtained in embodiment 1-1 to 1-5 is plotted to the scavenging effect of OH figure 1 . The optimal reaction pH of amylase was 6.0.

Embodiment 2-1

[0038] Accurately weigh 0.05g of Enteromorpha crude polysaccharide, add 5mL of acetic acid-sodium acetate buffer solution with a pH of 6.0, add 5mL of 100U / mL amylase solution, reaction time 1h, reaction temperature 50°C, ratio of solid to liquid 1:2000 (enzyme concentration 50U / mL), boil the enzymolysis solution after enzymolysis for 5min, centrifuge to remove the enzyme, adjust the pH of the supernatant to neutral with alkali, and set the volume to 20mL, and use the Fenton reaction system to measure the removal of OH by Enteromorpha polysaccharide after degradation effect.

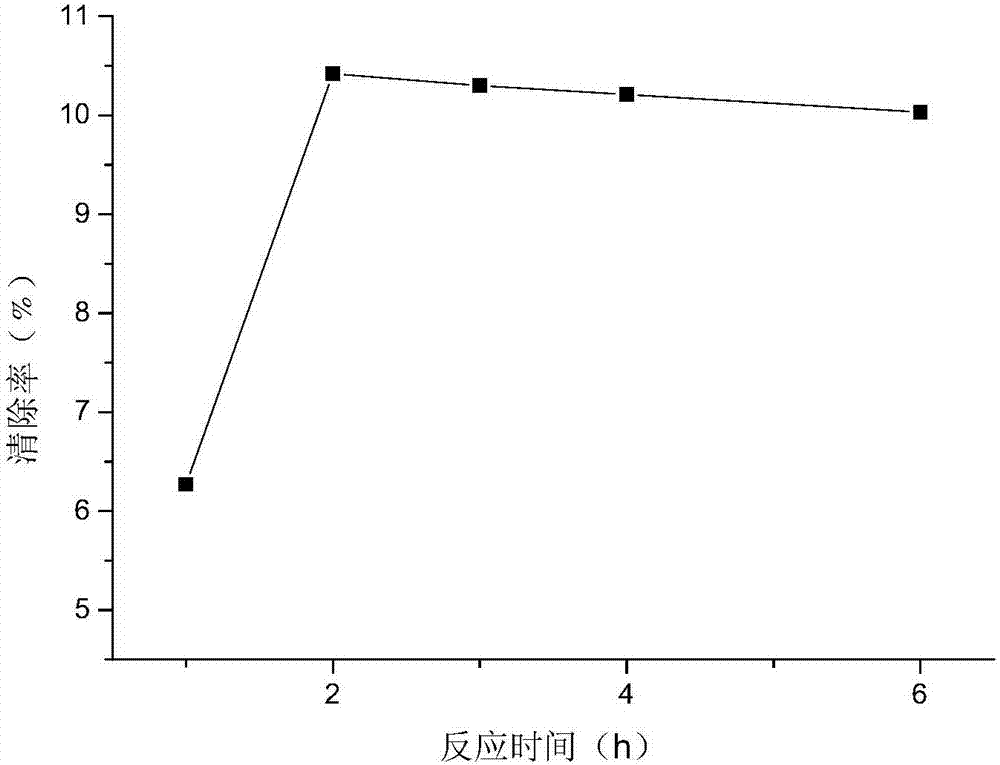

[0039] Change the reaction time in Example 2-1 from 1 h to 2, 3, 4, and 6 h respectively, and the rest are the same as Example 1-1 to obtain Examples 2-2, 2-3, 2-4, and 2-5.

[0040] The degraded Enteromorpha polysaccharide obtained in embodiment 2-1 to 2-5 is plotted to the scavenging effect of OH figure 2 . The optimal reaction time of amylase was 2h.

Embodiment 3-1

[0042]Weigh 0.05g of Enteromorpha crude polysaccharide, add 5mL of acetic acid-sodium acetate buffer solution with pH 6.0, add 5mL of 100U / mL amylase solution, reaction time 2h, reaction temperature 30°C, solid-liquid ratio 1:2000 (enzyme concentration 50U / mL), the enzymolysis solution after enzymolysis was boiled for 5 minutes, centrifuged to remove the enzyme, the supernatant was adjusted to neutral pH with alkali, and the volume was fixed to 20mL, and the Fenton reaction system was used to measure the scavenging of Enteromorpha polysaccharides to OH after degradation effect.

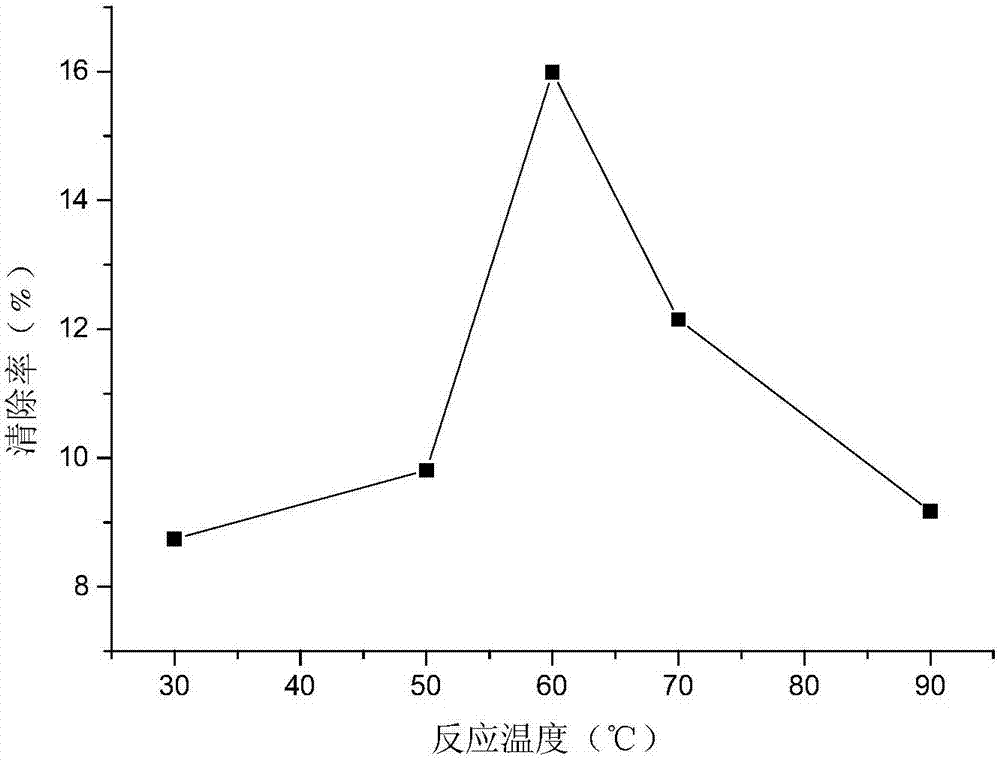

[0043] Change the reaction temperature in Example 3-1 from 30°C to 50, 60, 70, and 90°C respectively, and the rest are the same as in Example 3-1 to obtain Examples 3-2, 3-3, 3-4, and 3- 5.

[0044] The degraded Enteromorpha polysaccharide obtained in embodiment 3-1 to 3-5 is plotted to the scavenging effect of OH image 3 . The optimal reaction temperature of amylase was 60℃.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com