Demulsification device and method

A demulsification device and demulsification technology, which are applied in chemical instruments and methods, separation methods, grease/oily substances/floating matter removal devices, etc., can solve the problems of narrow application range, increased processing cost, long reaction time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

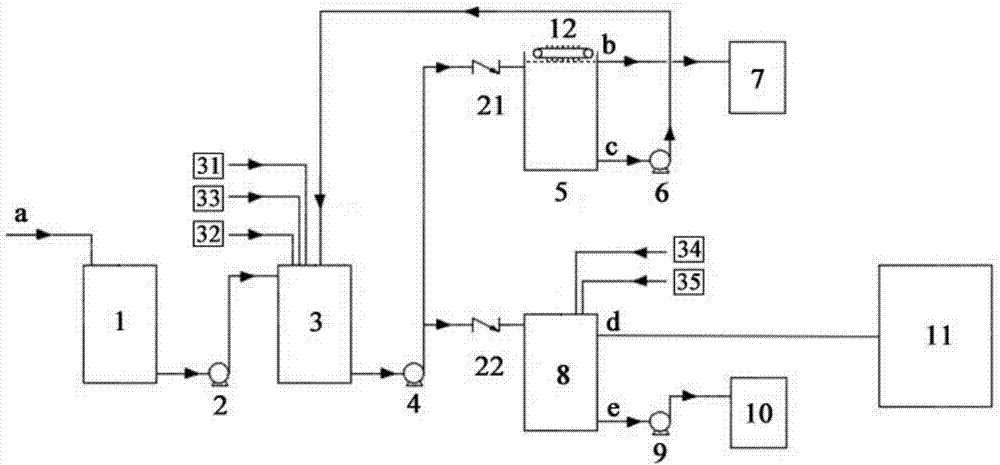

Method used

Image

Examples

Embodiment 1

[0057] The waste emulsion in this example was taken from the cutting fluid of a machining factory in Langfang. Table 1 is the water quality detection index of the cutting fluid. Among them, SS means suspended solids.

[0058] Table 1 Water quality detection index of a certain cutting fluid

[0059]

[0060] The cutting fluid contains less oil, and the solution is milky white, and is demulsified by directly demulsifying and precipitating. That is, in the emulsification device according to the present invention, the first passage (for example, the first valve) is closed / disconnected, and the second passage (for example, the second valve) is opened / connected.

[0061] The waste emulsion to be treated is introduced into the waste emulsion storage container, and then enters into the demulsification reaction container through the feed pump. Since the pH of the waste emulsion is 8, there is no need to add alkali, directly add 0.2% calcium chloride from the inorganic salt feeding p...

Embodiment 2

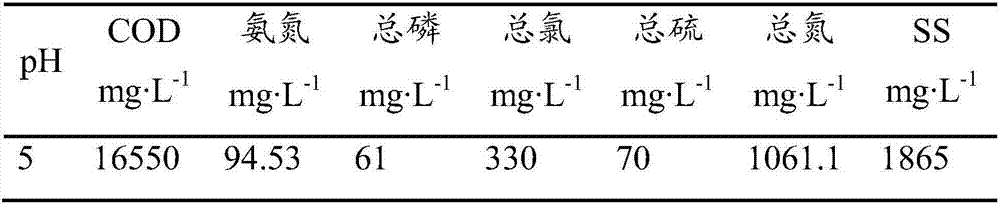

[0064] The waste emulsion was taken from a machine processing factory in Langfang. Table 2 is the water quality detection index of the waste emulsion.

[0065] Table 2 Water quality detection index of a certain waste emulsion

[0066]

[0067] The cutting fluid contains less oil, and the solution is milky white, and is demulsified by directly demulsifying and precipitating. That is, in the emulsification device according to the present invention, the first passage (for example, the first valve) is closed / disconnected, and the second passage (for example, the second valve) is opened / connected.

[0068] The waste emulsion to be treated is introduced into the waste emulsion storage container, and then enters into the demulsification reaction container through the feed pump. Since the pH of the waste emulsion is 5, directly add 0.1% calcium hypochlorite (which can not only break the emulsion, but also oxidize and degrade COD, and adjust the pH value) from the inorganic salt fe...

Embodiment 3

[0071] The waste emulsion was taken from a machine processing factory in Langfang. Table 3 is the water quality detection index of the waste emulsion.

[0072] Table 3 Water quality detection index of a certain waste emulsion

[0073]

[0074] The cutting fluid contains less oil, and the solution is milky white, and is demulsified by directly demulsifying and precipitating. That is, in the emulsification device according to the present invention, the first passage (for example, the first valve) is closed / disconnected, and the second passage (for example, the second valve) is opened / connected.

[0075] The waste emulsion to be treated is introduced into the waste emulsion storage container, and then enters into the demulsification reaction container through the feed pump. Since the pH of the waste emulsion is 9, first adjust the pH to 7 by the strong acid dosing pump, then add 0.5% magnesium chloride by the inorganic salt feeding pump, stir for 5 minutes at a speed of 300r / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com