Novel method for preparing graphene with glycerol as liquid phase by using planetary muller through wet method

A technology of planetary ball mill and glycerol, applied in the direction of graphene, nano-carbon, etc., can solve the problems that hinder the application of graphene, the quality of graphene is uneven, and the size of graphene is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

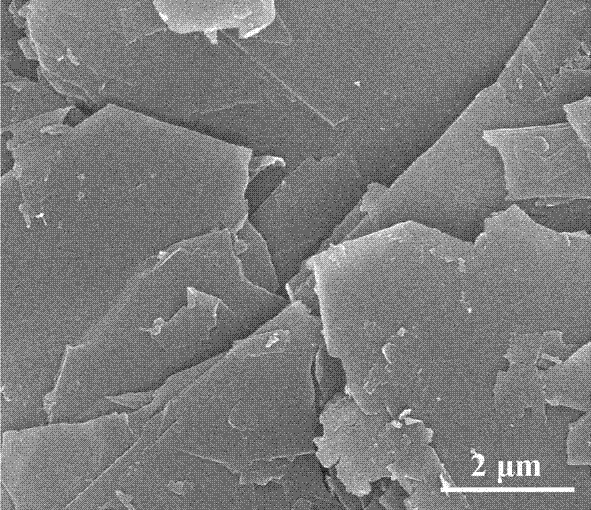

Image

Examples

Embodiment 1

[0013] 1. Weigh 2g of graphite and place it in a ceramic jar and control the volume ratio of graphite in the ceramic jar to 1:1.5, then calcined in a muffle furnace at 300°C for 2 hours, and place the calcined expanded graphite in Serve in a brown glass container;

[0014] 2. Weigh 1g of expanded graphite, put it in a beaker, then pour 20ml of glycerol organic solution at a certain temperature into the beaker, and stir it ultrasonically for 60 minutes before use; control the molar ratio of graphite to ethanol to 1:4, The ultrasonic power range is 200W, and the glycerin organic solution is kept at 35°C for 300min before use, and the stirring temperature is controlled at 35°C;

[0015] 3. Pour the above liquid into the insulated agate jar, shake it to a uniform state, then put the agate jar on the planetary ball mill, after 500 rpm / min and 3h, pour out the liquid in the agate jar, and use a deionized After water centrifugation, the supernatant was taken and freeze-dried for 24 ...

Embodiment 2

[0017] 1. Weigh 3g of graphite and place it in a ceramic jar and control the volume ratio of graphite in the ceramic jar to 1:2, then calcined in a muffle furnace at 280°C for 3 hours, then place the calcined expanded graphite in Serve in a brown glass container;

[0018] 2. Weigh 0.5g of expanded graphite, put it in a beaker, then pour 15ml of glycerol organic solution at a certain temperature into the beaker, and stir it ultrasonically for 80min before use; control the molar ratio of graphite to ethanol to 1:3.5 , the ultrasonic power range is 300W, and the glycerin organic solution is kept at 30°C for 40 minutes before use, and the stirring temperature is controlled at 30°C;

[0019] 3. Pour the above liquid into the insulated agate jar, shake it to a uniform state, then put the agate jar on the planetary ball mill, after 400 rpm / min and 4h, pour out the liquid in the agate jar, and use a deionized After water centrifugation, the supernatant was taken and freeze-dried for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com