Processing method of high-quality instant crisp water chestnut chips and crisp water chestnut chips

A technology of water chestnut chips and a processing method, applied in the field of food processing, can solve the problems of high cost, long drying time, non-enzymatic browning and the like, and achieves the effects of fast drying rate, high drying efficiency and inhibition of polyphenol oxidase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

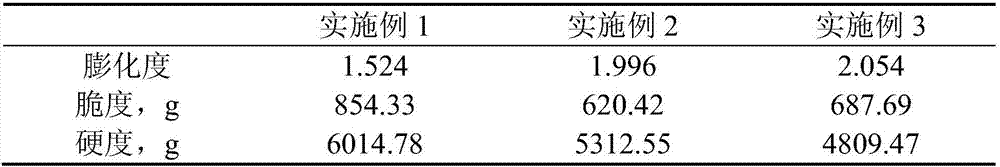

Examples

Embodiment 1

[0047] The processing method of the high-quality instant water chestnut chips of the present embodiment is:

[0048] (1) Select peeled slices: select fresh water chestnuts with the same size and no pests, peel the selected water chestnuts with a peeling machine, clean them according to the processing requirements of water chestnuts, and slice the peeled water chestnuts with a slicer. The thickness of the slices remains constant. Consistent, the thickness is 10mm;

[0049] (2) color protection: use color protection liquid to carry out color protection treatment to water chestnut slices, the soaking time of described color protection treatment is 1h;

[0050] (3) Pre-drying: pre-drying the water chestnut slices after the color protection treatment to obtain pre-dried water chestnut chips; pre-drying adopts hot air drying, the temperature of the hot air drying is 60°C, and the wind speed is 1.5m / s. The time is 120min;

[0051] (4) Air puffing: Carry out air puffing treatment to...

Embodiment 2

[0056] The difference between this embodiment and embodiment 1 is:

[0057] In step (3), vacuum drying is used for pre-drying, the temperature of the vacuum drying is 40°C, the pressure is -0.01MPa, and the time is 300min;

[0058] In step (4), when the temperature in the expansion tank is 85° C. and the pressure is 0.2 MPa, keep it for 15 minutes, open the vacuum valve, and instantly connect the expansion tank and the vacuum tank, thereby causing the pressure in the expansion tank to drop suddenly from 0.2 MPa to -0.0094MPa; In the process of dehumidification treatment, every time the pressure rises from -0.0094MPa to normal pressure, it is considered as a dehumidification treatment.

[0059] In step (5), the seasoning is to spray hot palm oil and the second seasoning successively on the surface of the water chestnut chips, by weight of the water chestnut chips, the hot palm oil is 3wt%, and the second seasoning is 7wt%, the oil temperature of the hot palm oil is 55°C; in pa...

Embodiment 3

[0061] The difference between this embodiment and embodiment 1 is:

[0062] In step (3), the pre-drying adopts medium-short-wave infrared drying, and the temperature of the medium-short-wave infrared drying is 90° C., and the time is 55 minutes;

[0063] In step (4), when the temperature in the expansion tank is 95°C and the pressure is 0.25 MPa, keep it for 15 minutes, open the vacuum valve, and make the expansion tank and the vacuum tank instantly connected, thereby causing the pressure in the expansion tank to drop from 0.25 MPa to -0.0096MPa, in the process of dehumidification treatment, every time the pressure rises from -0.0096MPa to normal pressure, it is considered as a dehumidification treatment.

[0064] In step (5), the seasoning is to spray hot palm oil and the third seasoning successively on the surface of the water chestnut chips, by weight of the water chestnut chips, the hot palm oil is 3wt%, and the third seasoning is 7wt%, the oil temperature of the hot palm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com