Photoelectric effect tester

A photoelectric effect and tester technology, which is applied in the direction of instruments, measuring device shells, and sound-generating instruments, can solve the problems of no protective shell, no heat dissipation plate, and no sound-absorbing board, etc., so as to increase the air circulation speed and structure. Scientific and reasonable, safe and convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

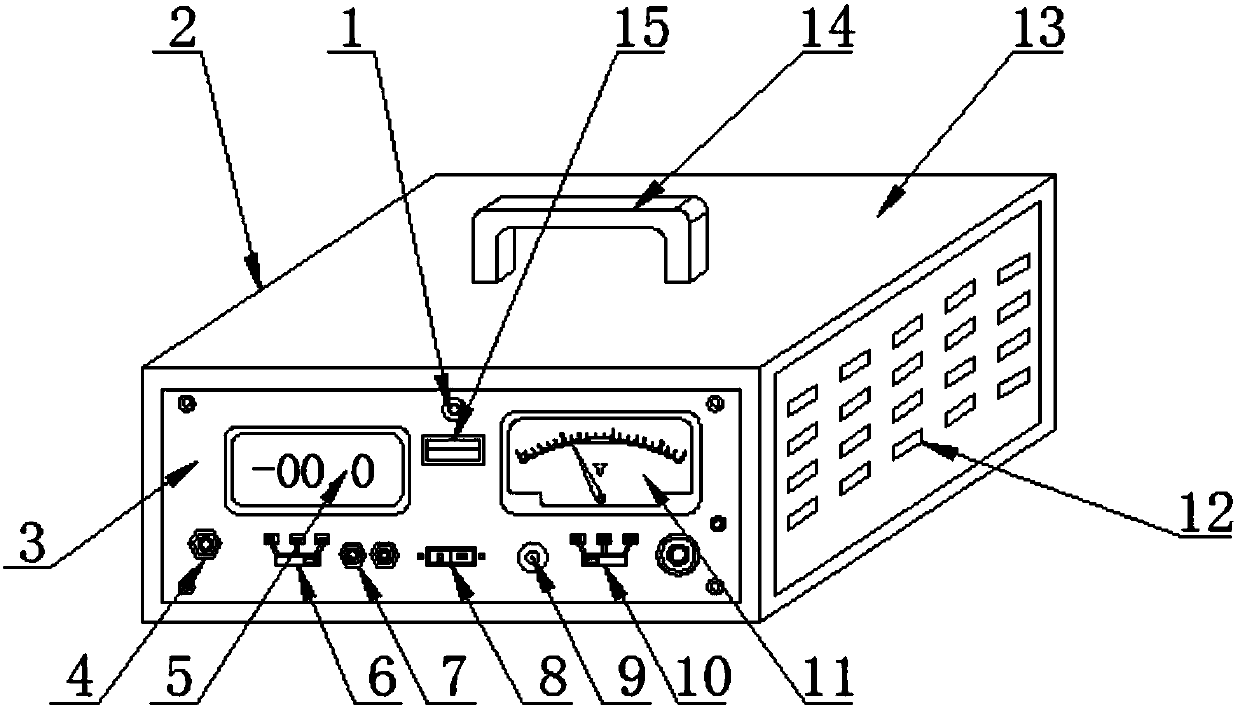

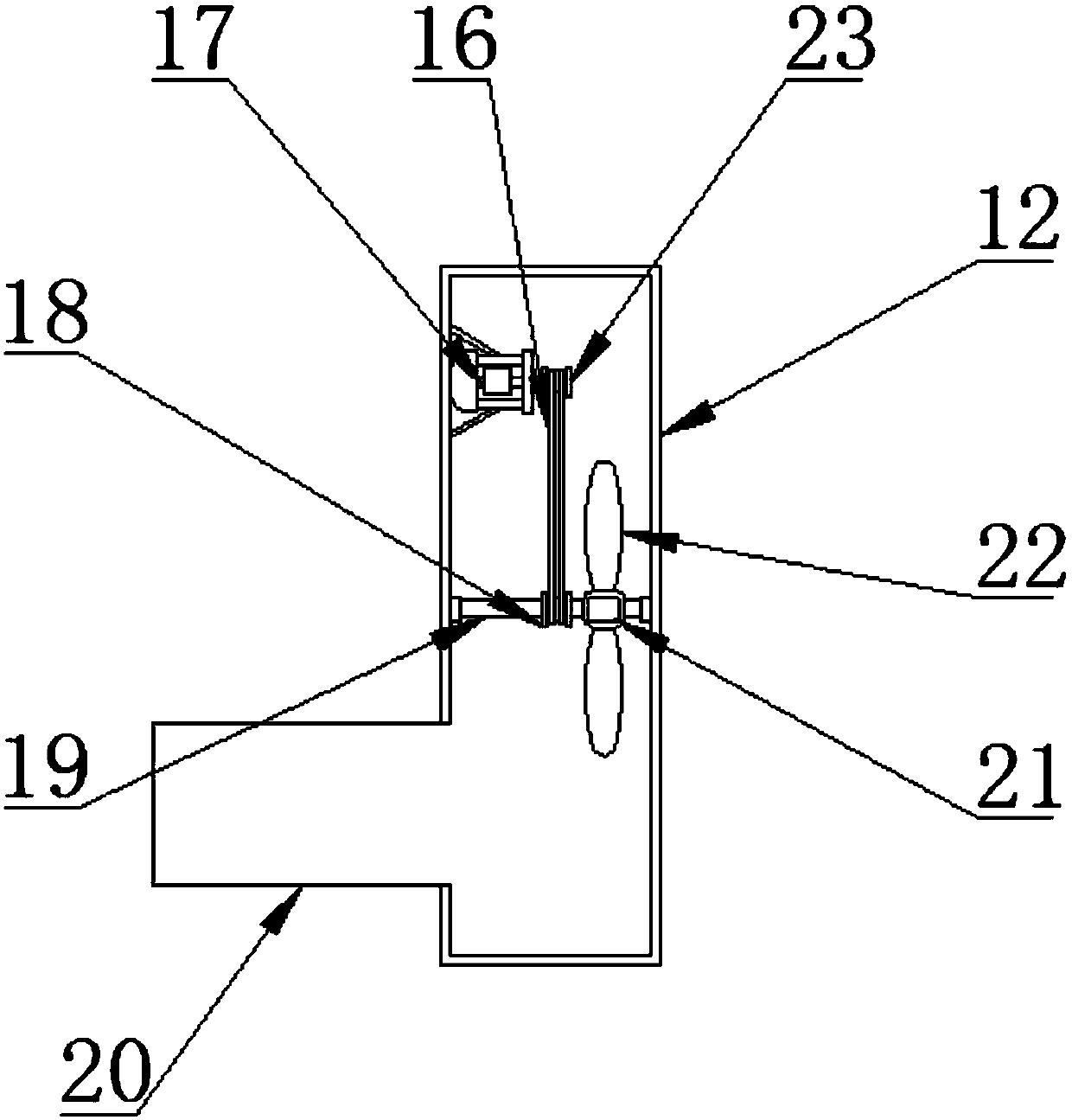

[0024] Example: such as Figure 1-5 As shown, the present invention provides a technical solution, a photoelectric effect tester, including a charging indicator light 1, a protective case 2, a tester body 3, a voltage input interface 4, a test display screen 5, a current control button 6, a voltage output Interface 7, switch 8, voltage polarity knob 9, voltage control button 10, voltage display meter 11, cooling plate 12, upper cover plate 13, handle 14, USB charging interface 15, belt 16, motor 17, driven pulley 18, Fixed rod 19, sound-absorbing plate 20, fixed seat 21, fan blade 22, driving pulley 23, support foot 24, leveling screw rod 25, first damping spring 26, air inlet plate 27, first buffer plate 28, second damper Shock spring 29 and the second buffer plate 30, the outside of the tester body 3 is fixed with a protective case 2, and the front surface of the tester body 3 is embedded with a test display screen 5, which is close to the test display screen on the tester b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com