Low-pollution combustor head structure with main combustion stage oblique jetting nozzle

A technology of injection nozzle and main combustion stage, which is applied in the combustion chamber, continuous combustion chamber, combustion method, etc., can solve the problems of increasing the premixed air opening angle, high pollutant emission, and increasing the combustion range, and achieves enhanced ignition. performance, reduce pollution emissions, enhance the effect of mixing intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Describe the present invention in detail below in conjunction with accompanying drawing and specific embodiment:

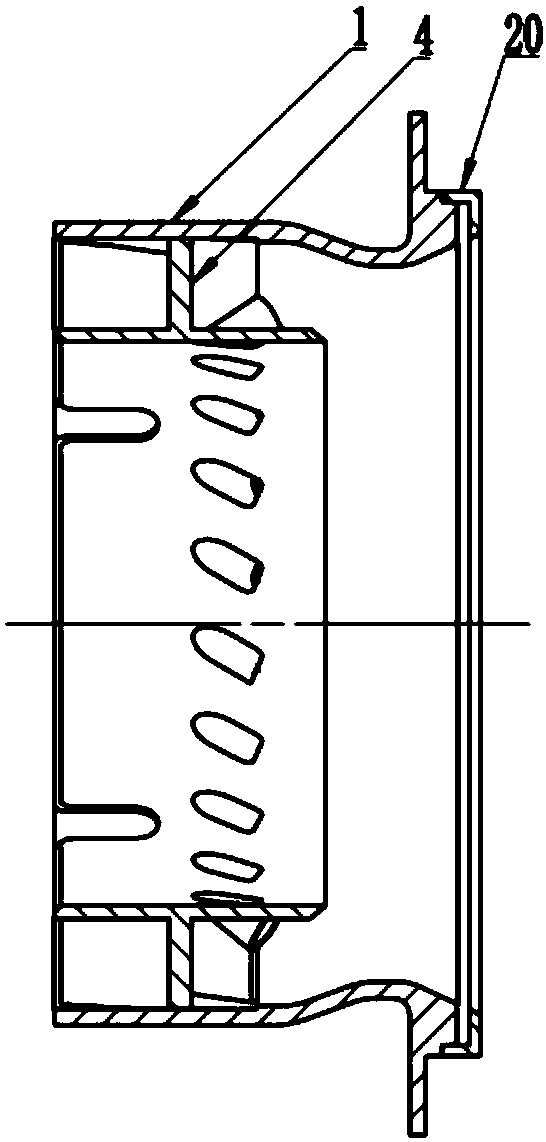

[0028] Such as figure 1As shown in this example, a main combustion stage adopts a low-pollution combustion chamber head structure with oblique injection nozzles, adopts oblique injection nozzles and a central staged structure design, and is made of stainless steel as a whole, and the burner part includes: main The combustion stage, the main combustion stage includes the main combustion stage casing 1, the main combustion stage swirl vane 4, the main combustion stage fuel injection hole 6, the main combustion stage inner ring 2, the main combustion stage inner ring outer 3, the main combustion stage premixing The channel 7 and the gas blocking ring 20; the pre-combustion stage includes the pre-combustion stage primary swirler 13, the venturi tube 14, the pre-combustion stage secondary swirler 15; the pneumatic diversion pipeline includes the inside of the se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com