Fracturing technique for achieving complex crack through multiple particle class differential temporary blocking

A technology with complex fractures and multiple particle sizes, which is applied in the direction of drilling composition, production fluid, wellbore/well components, etc., can solve the problems of difficult treatment, low oil recovery rate, low recovery degree, etc., and achieve technological progress Simple and easy to implement, expand the degree of use, and improve the effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

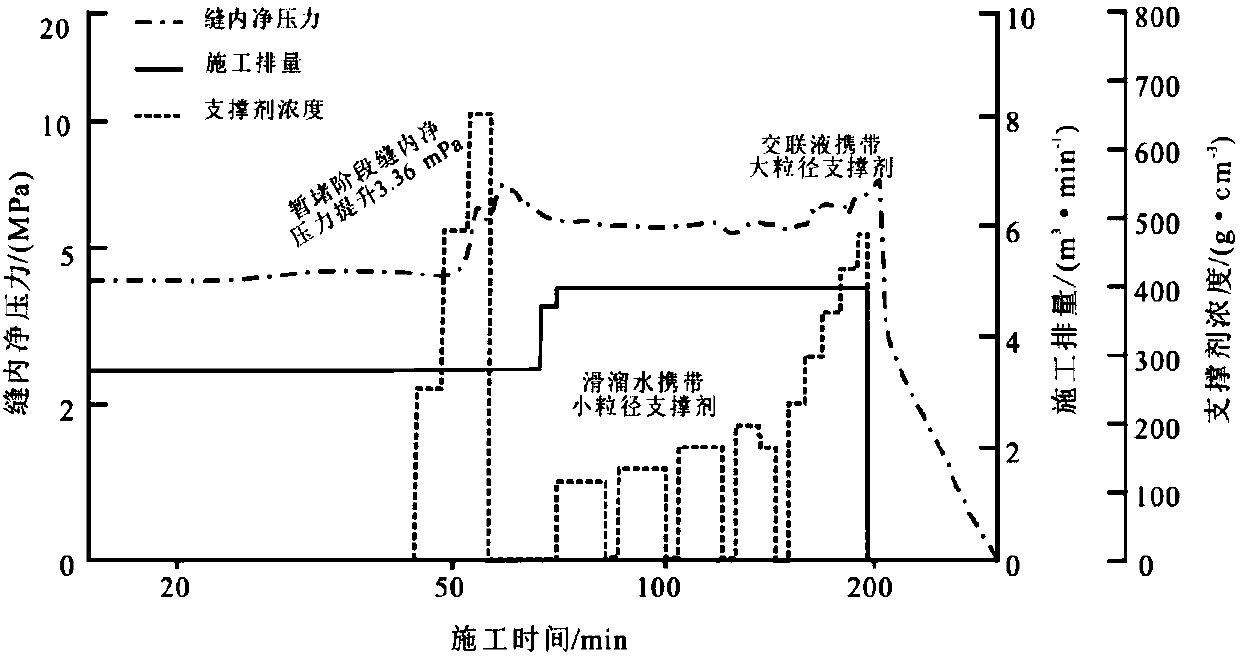

[0038] In order to solve the problem that the ultra-low permeability oilfield has a long production time and the lateral remaining oil is difficult to produce, while the conventional refracturing technology is difficult to realize the effective production of the remaining oil, the implementation effect is poor, and the effective period of the measures is short. This embodiment provides a Such as figure 1 and figure 2 The shown fracturing process for realizing complex fractures based on temporary plugging of various particle size differences includes the following steps:

[0039] Step 1: Preparation of construction materials:

[0040] (1) Plugging agent preparation: Mix four rigid temporary plugging agents with a particle size of 2.36-3.35mm, 0.85-2.00mm, 0.21-0.45mm and 0.12-0.15mm according to the mass ratio of 1:1:2:4 and mix them evenly , forming a temporary plugging agent composition with various particle size differences;

[0041] (2) Preparation of fiber fracturing f...

Embodiment 2

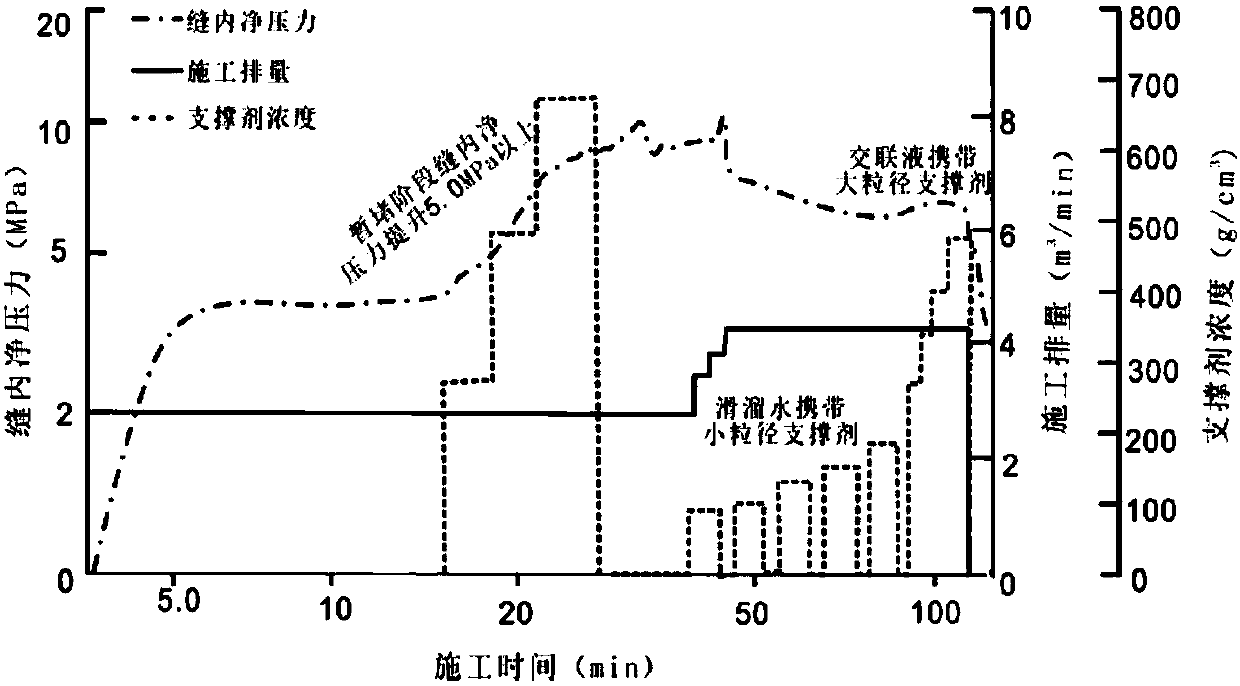

[0048] This embodiment provides a figure 1 and image 3 The shown fracturing process for realizing complex fractures based on temporary plugging of various particle size differences includes the following steps:

[0049] Step 1: Preparation of construction materials:

[0050] (1) Plugging agent preparation: Mix four rigid temporary plugging agents of 2.36-3.35mm, 0.85-2.00mm, 0.21-0.45mm and 0.12-0.15mm evenly according to the mass ratio of 1:1:2:4 to form multiple A temporary plugging agent composition with particle size difference;

[0051] (2) Preparation of fiber fracturing fluid: first prepare a guar gum base fluid with a mass concentration of 0.3%, and use the guar gum base fluid as a mother liquor to prepare a degradable polylactic acid resin fiber fracturing fluid with a mass concentration of 0.6% as a carrier fluid;

[0052] Step 2: Use active water at 0.5m 3 / min construction displacement to replace the liquid in the wellbore at a low rate, and use 0.5-3.0m 3 / m...

Embodiment 3

[0059] (1) Plugging agent preparation: Mix four rigid temporary plugging agents with a particle size of 2.36-3.35mm, 0.85-2.00mm, 0.21-0.45mm and 0.12-0.15mm according to the mass ratio of 1:1:2:4 and mix them evenly , forming a temporary plugging agent composition with a particle size difference;

[0060] (2) Preparation of fiber fracturing fluid: first prepare a guar gum base fluid with a mass concentration of 0.3%, and use the guar gum base fluid as a mother liquor to prepare a degradable polylactic acid resin fiber fracturing fluid with a mass concentration of 0.6% as a carrier fluid .

[0061] Step 2: Use active water at 0.5m 3 / min construction displacement to replace the liquid in the wellbore at a low rate, and use 0.5m 3 / min construction displacement to set the packer to ensure that the follow-up construction liquid and sand enter the formation;

[0062] Step 3: First set the size greater than 3.0m 3 The construction displacement per minute injects 40m of water r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com