Lift and tower crane

A technology for elevators and tower cranes, applied in the field of elevators and tower cranes, can solve problems such as easy wear and tear of guide rails, safety accidents, etc., and achieve the effects of improving safety performance and comfort performance, stable connection, and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

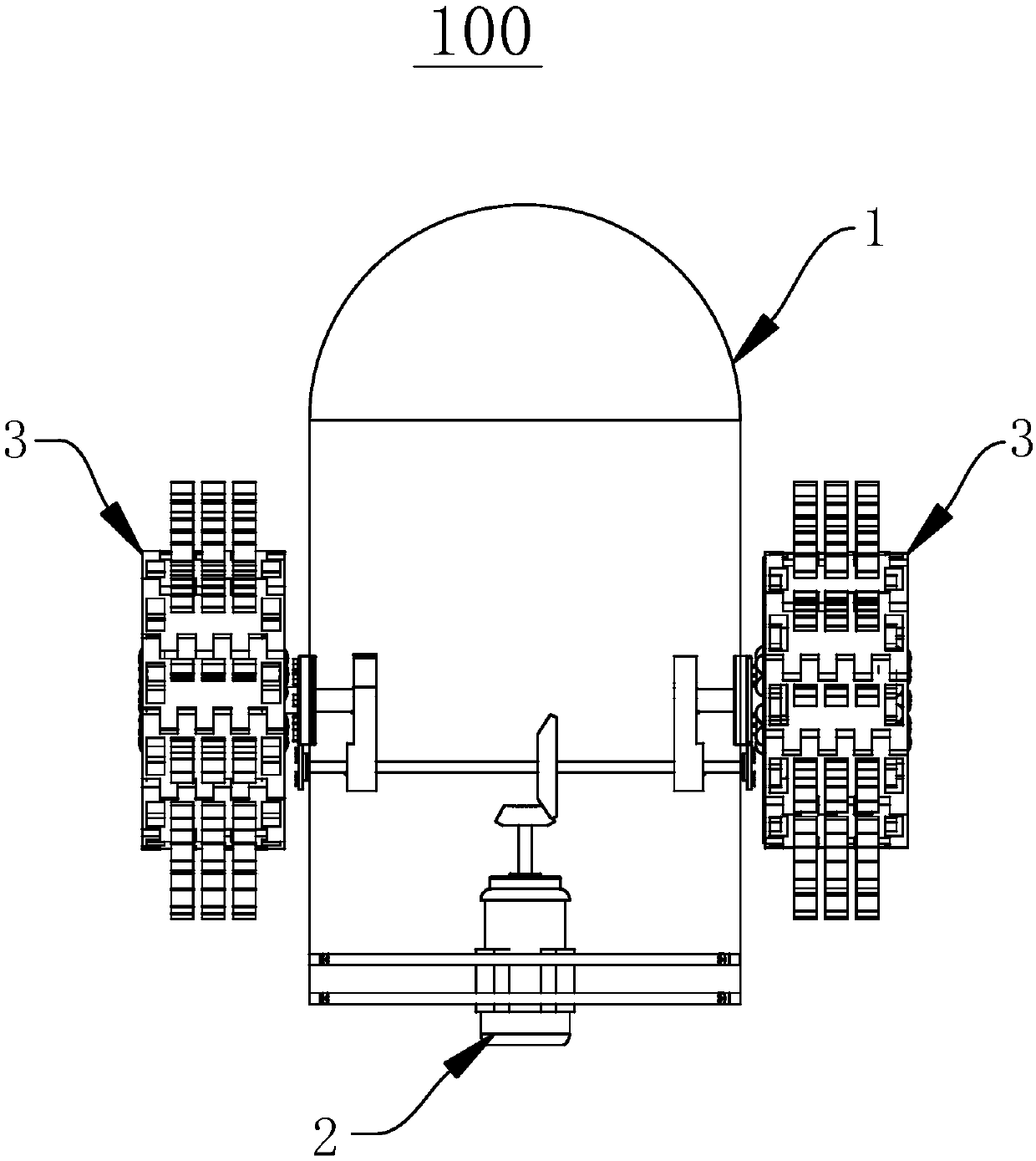

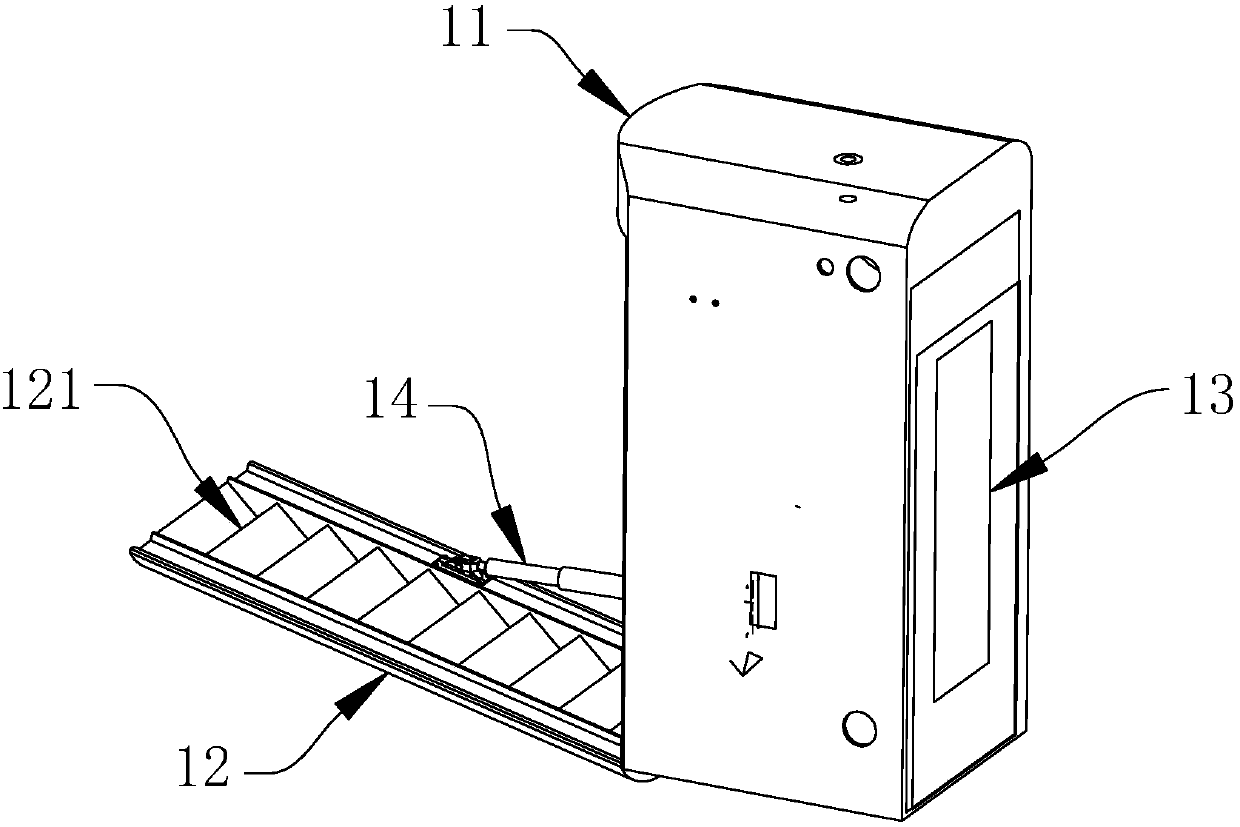

[0035] Please refer to figure 1 , this embodiment provides an elevator 100 , which is applied to a tower crane, and includes a car 1 , a driving mechanism 2 and two crawling mechanisms 3 .

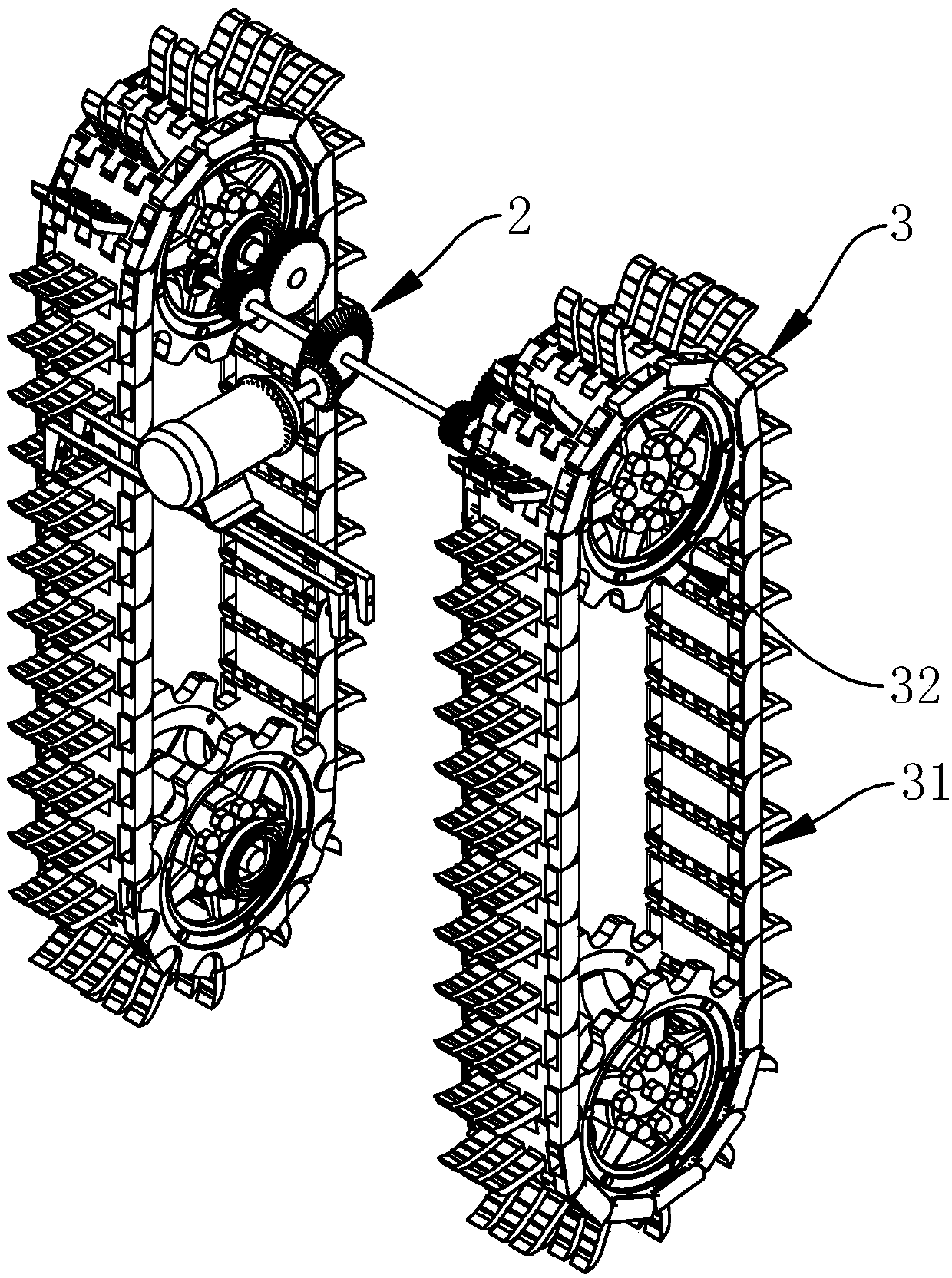

[0036] In this embodiment, the driving mechanism 2 is detachably arranged on the car 1, and it is convenient to overhaul the driving mechanism 2 during use; Balanced, the driving mechanism 2 is located between two crawling mechanisms 3. The crawling mechanism 3 includes a crawler belt 31, a driving wheel set 32 and a spur assembly. The crawler belt 31 is a chain ring structure, and the driving wheel set 32 is located in the chain ring. The driving wheel set 32 It is connected with the driving mechanism 2, and the driving wheel set 32 is used to drive the crawler belt 31 to rotate. The shoe shoe assembly is arranged around the axial direction of the crawler belt 31. The shoe shoe assembly is used to cooperate with the ladder of the tower crane and hang the crawler mechanism 3 on the t...

no. 2 example

[0060] Please refer to Figure 9 As shown, this embodiment provides a tower crane 400, including a tower crane body 41, a counterweight 42 and the elevator 100 provided in the first embodiment.

[0061] In this embodiment, the tower crane body 41 includes a plurality of standard sections 411, and the plurality of standard sections 411 are stacked vertically to form a tower hanger, such as Figure 10 As shown, the standard section 411 includes a plurality of steps 412 distributed along the length of the standard section 411, and the two ends of the steps 412 are respectively fixed to the standard section 411. The plurality of steps 412 is equivalent to the track for the elevator 100 to move on the tower crane 400. The steps 412 are used for Cooperate with thorn group 33. In order to keep the elevator 100 balanced when moving on the tower crane 400 , a balance weight 42 is provided on the side of the tower crane 400 opposite to the elevator 100 . Balance weight 42 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com