Converter valve fire extinguishing device

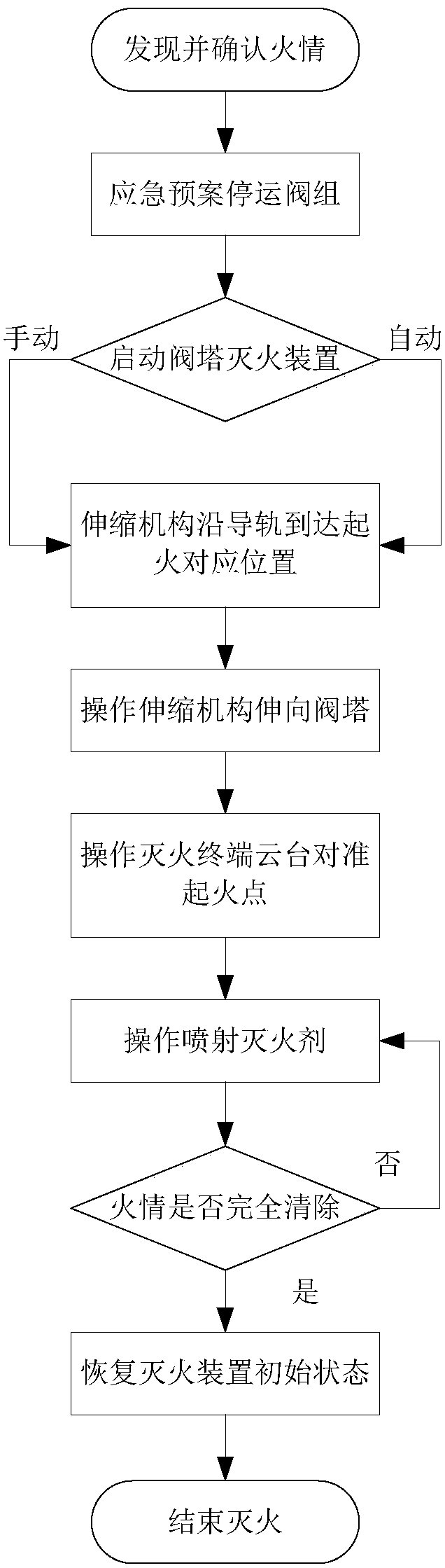

A technology of fire extinguishing device and converter valve, which is applied in fire rescue and other directions, can solve the problems of personal safety threat and low degree of automation, and achieve the effect of wide fire extinguishing range, improving fire extinguishing efficiency, and avoiding the spread of fire.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

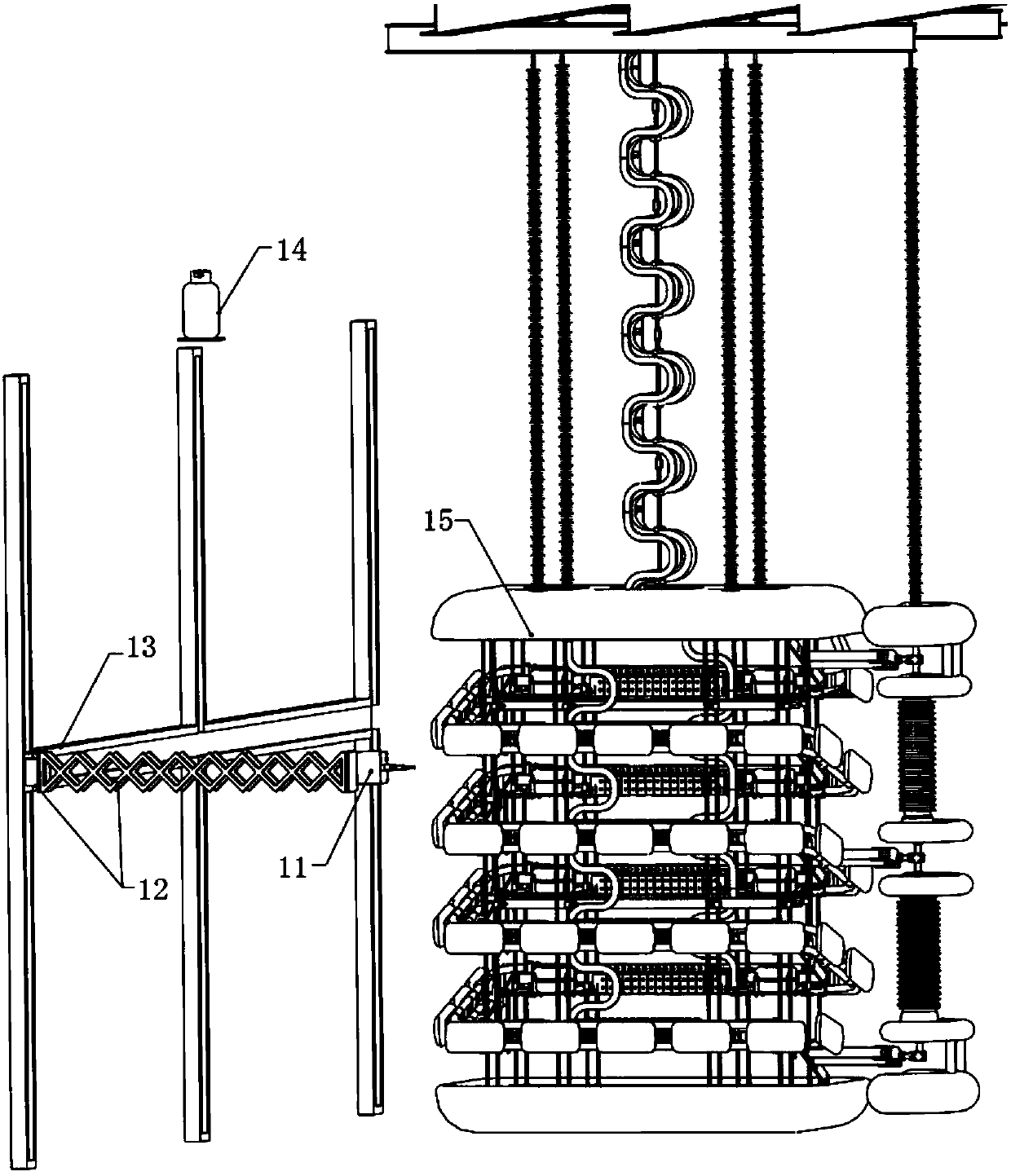

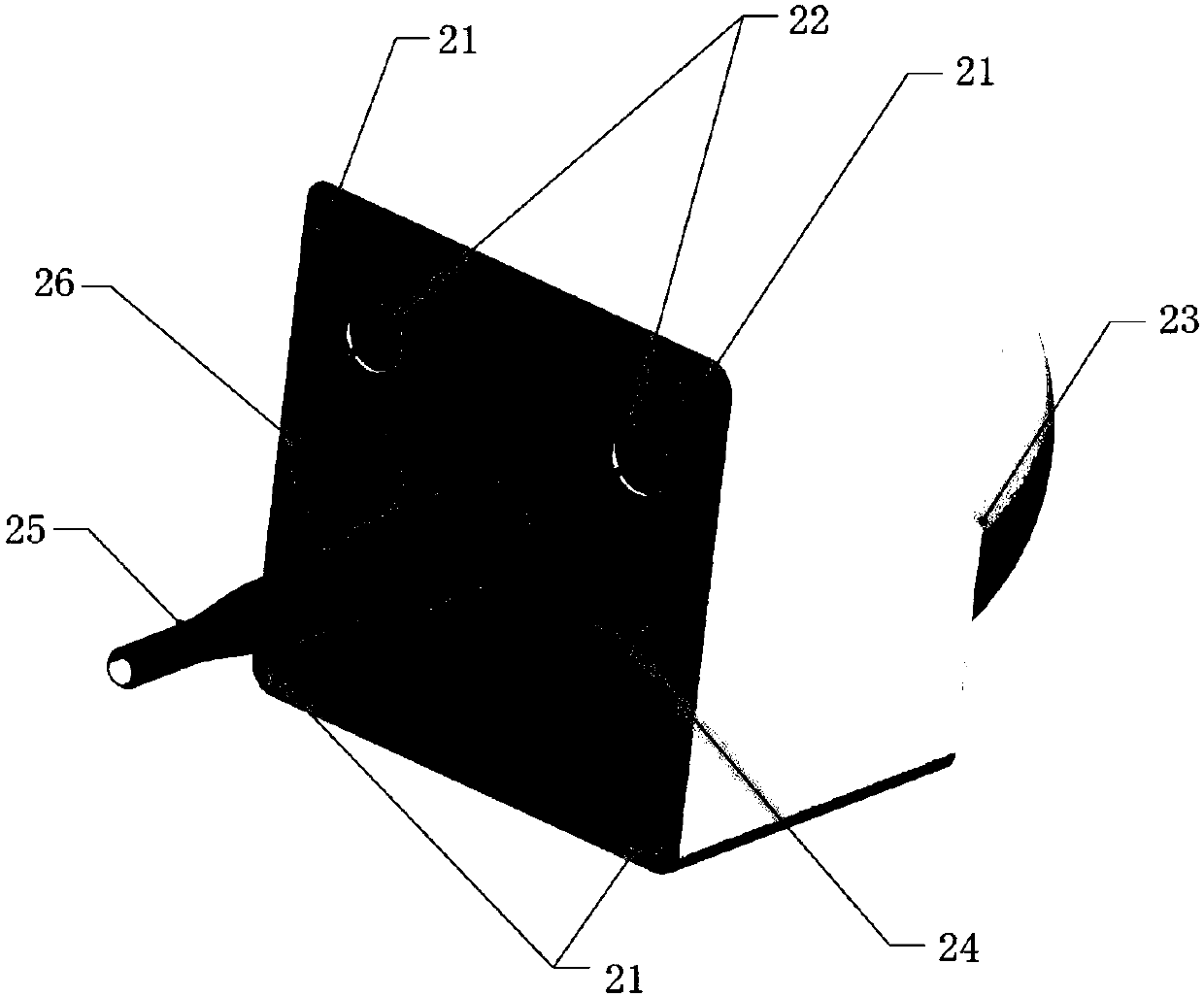

[0040] Such as Figure 4 , 5 As shown, the fire extinguishing device guide rail 13 is a side-mounted rail frame, and the side-mounted rail frame is in a side-mounted plane. The side-mounted plane is perpendicular to the horizontal plane and includes a first rail 31 arranged horizontally. A motion mechanism 32, the first motion mechanism 32 is provided with a second track 33, the second track 33 is provided with a second motion mechanism 34 for guiding movement, and the second track 33 and the first track 31 are intersected in a lateral plane. The shapes of the first track 31 and the second track 33 are not fixed, for example, they may be linear, curved, etc. The second movement mechanism 34 is connected with a hydraulic-mechanical telescopic mechanism 12 and a driving mechanism for driving the telescopic mechanism to expand or contract. The hydraulic-mechanical telescopic mechanism 12 drives the fire extinguishing device injection terminal 11 provided at its end.

[0041] Fi...

Embodiment 2

[0043] Such as Figure 6 As shown, the guide rail 13 of the fire extinguishing device is a side-mounted track frame, and the side-mounted track frame is in a side-mounted plane. The side-mounted plane is perpendicular to the horizontal plane and includes at least two rails arranged crosswise. A movement mechanism 41 is provided for guiding movement on the rails. The movement mechanism 41 is connected with a hydraulic mechanical telescopic mechanism 12 and a driving mechanism that drives the hydraulic mechanical telescopic mechanism 12 to expand or contract. The hydraulic mechanical telescopic mechanism 12 drives the fire extinguishing device injection terminal 11 provided at its end. The shape of these tracks is also not fixed, and can be straight, curved or the like.

[0044] Driven by the driving mechanism, the spray terminal 11 of the fire extinguishing device can move freely along the track. Such as Figure 6 As shown, move to the dotted line position in the figure along...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com