Inner spiral eye socket wheel seed manure disk

A technology of internal helix and eyelet wheel, applied in fertilizer and seeding equipment, etc., can solve the problems of waste of resources, increase of cost of machinery and tools, etc., and achieve the effect of reducing economic cost, reliable quality and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

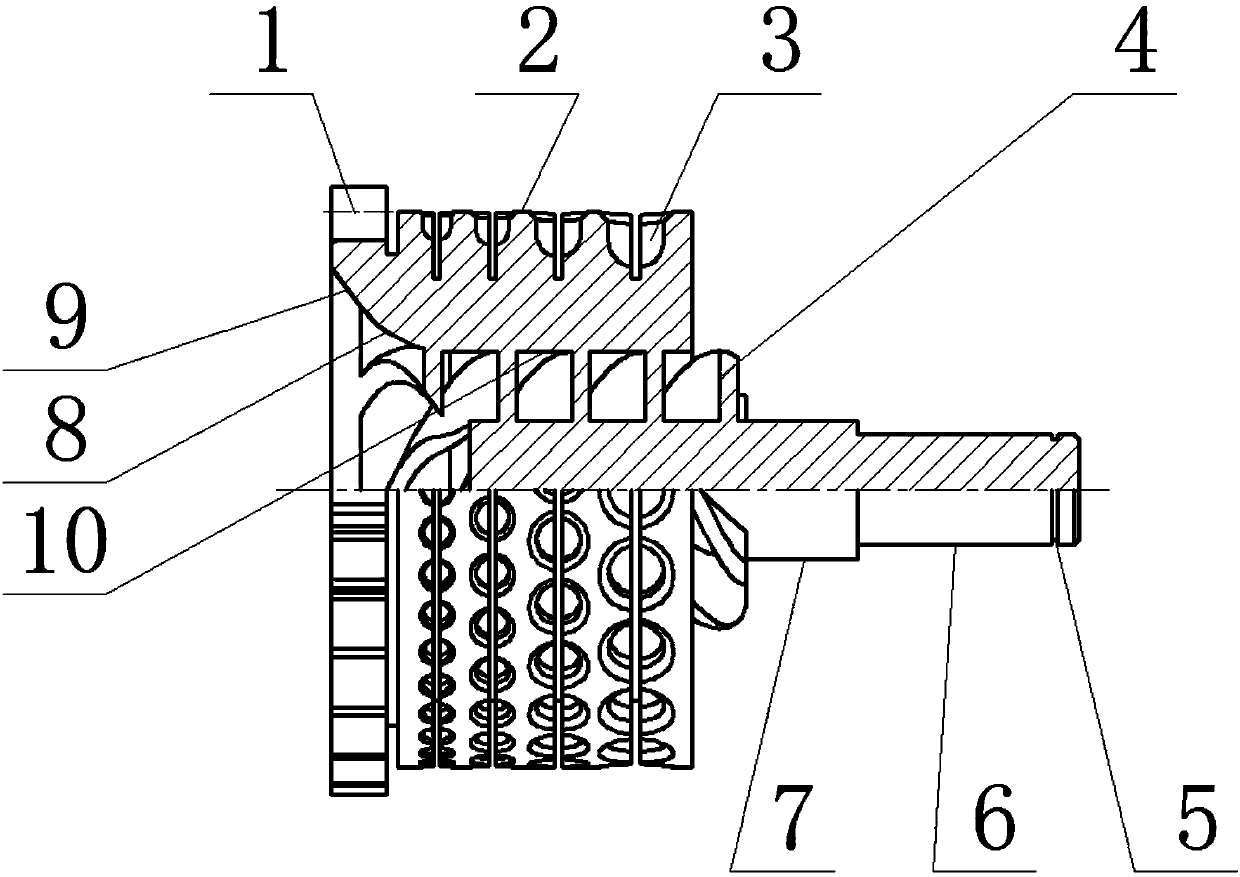

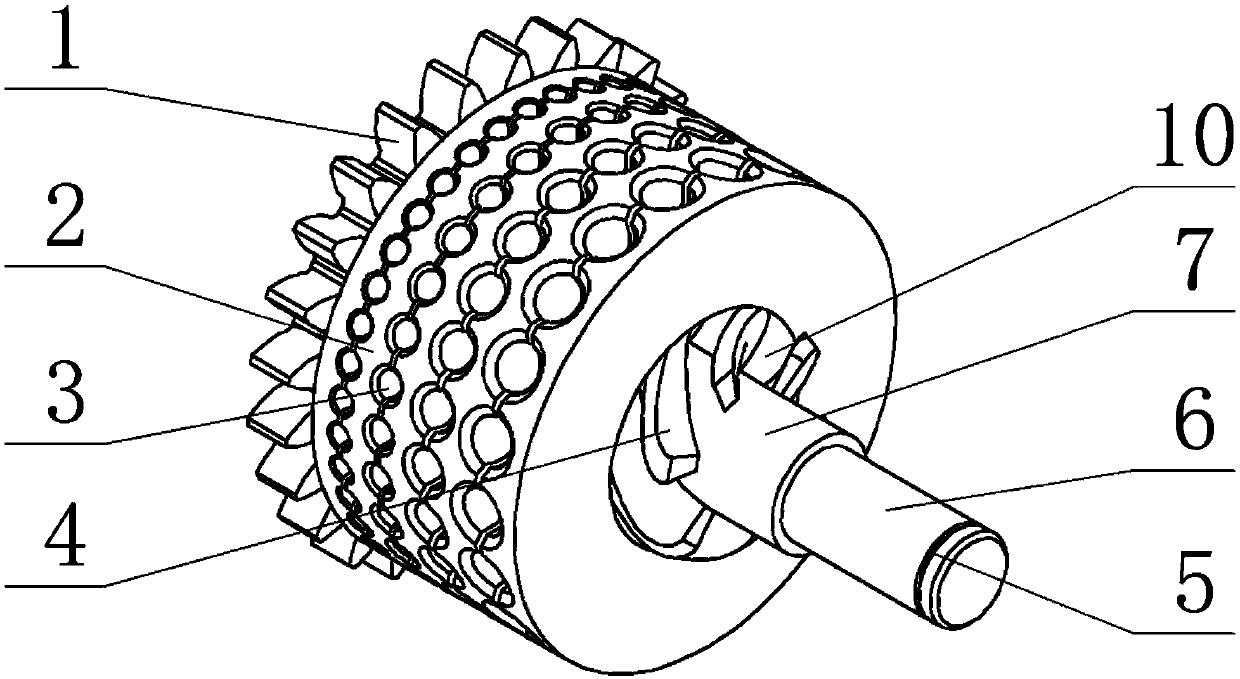

[0011] Below in conjunction with accompanying drawing, the embodiment that the present invention creates is described in detail:

[0012] An inner spiral nest wheel seeding tray, an external gear 1 is arranged on the outer edge of the left end of the inner spiral nest wheel seeding tray, two circumferentially evenly filled seed pockets 3 are arranged on the outer cylindrical surface of the middle part, and a circlip is arranged on the right end from left to right Groove 5, bearing shaft section 6 and fertilization cylinder 7, the inner spiral fertilization blade 4 is evenly distributed in the circumferential direction between the fertilization cylinder 7 and the inner cylindrical surface 10, and the left end of the fertilization cylinder 7 is inside the external gear 1 Set the curved conical cylinder surface 8 and the straight conical cylinder surface 9 in sequence.

[0013] When the internal spiral socket wheel is used for planting fertilizer, the plate is connected to the ho...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap