Wire wrapping support sealing piece

A technology of seals and supports, applied in the direction of electrical components, etc., can solve the problem of unstable sealing effect in the life cycle, achieve stable structure, high sealing effect, and ensure the effect of sealing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In Embodiment 1, the axial bending of the inner liner is arc-shaped, so that the support is arc-shaped. Further, among the three parts of the two ends and the middle of the arc-shaped support, any one part is located at a different position from the other two parts. In a two-dimensional plane, in order to meet the requirements of conforming to the structure of the seal.

Embodiment 2

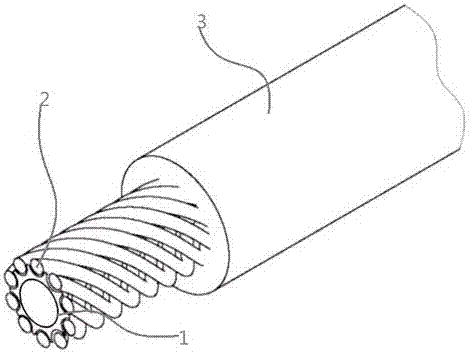

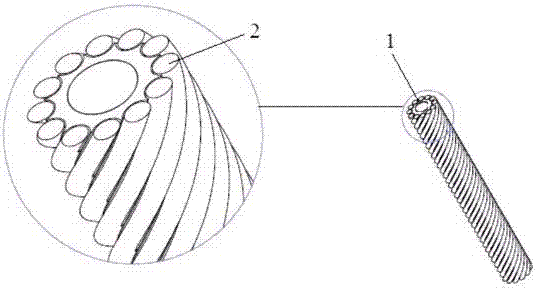

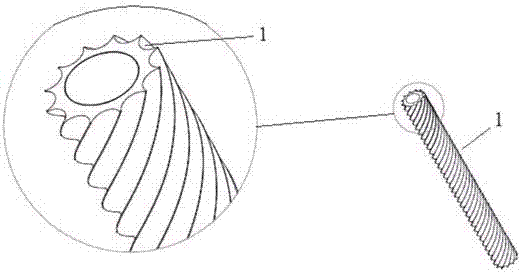

[0038] In embodiment 2, the inner liner is axially bent in a spiral shape. Further, each winding groove is spirally arranged along the outer periphery of the inner liner. There are 12 winding grooves arranged on the outer periphery of the inner liner. The spacing is set, and the 12 winding slots correspond to 12 metal wires to form a complete support and cooperate with the inner lining to strengthen its structural strength.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com